Kev ua cov hlau ntawv

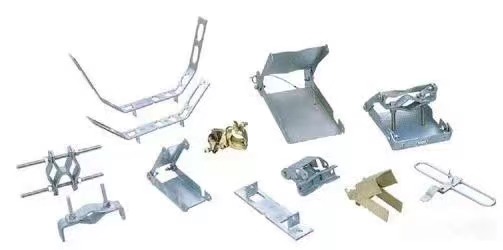

Kev ua cov hlau ntawv yog ib qho thev naus laus zis tseem ceeb uas cov kws kho hlau ntawv yuav tsum nkag siab, thiab nws kuj yog ib qho txheej txheem tseem ceeb hauv kev tsim cov khoom hlau ntawv. Kev ua cov hlau ntawv suav nrog kev txiav ib txwm muaj, kev ua kom dawb, kev khoov thiab kev tsim cov txheej txheem thiab cov txheej txheem txheej txheem, nrog rau ntau yam qauv pwm txias thiab cov txheej txheem txheej txheem, ntau yam khoom siv ua haujlwm thiab cov txheej txheem ua haujlwm, thiab cov thev naus laus zis tshiab thiab cov thev naus laus zis tshiab. Kev ua cov hlau ntawv feem ntau hu ua kev ua cov hlau ntawv.

Kev ua cov hlau ntawv hu ua kev ua cov hlau ntawv. Piv txwv li, kev siv cov phaj los ua cov pa taws, cov thoob hlau, cov thoob roj, cov thoob roj, cov kav dej cua, lub luj tshib, lub luj tshib, cov plaub fab, cov raj, thiab lwm yam. Cov txheej txheem tseem ceeb suav nrog kev txiav, khoov, khoov, tsim, vuam, riveting, thiab lwm yam. Qee qhov kev paub txog geometric. Cov hlau ntawv yog cov hlau ntawv nyias nyias, uas yog, cov khoom uas tuaj yeem ua tiav los ntawm kev ntaus, khoov, ncab thiab lwm yam. Lub ntsiab lus dav dav yog ib feem nrog qhov tuab tas li thaum lub sijhawm ua tiav. Sib xws rau kev castings, forgings, machining qhov chaw, thiab lwm yam.

Kev xaiv cov khoom siv

Cov ntaub ntawv feem ntau siv rau hauv kev ua cov hlau ntawv yog cov phaj txias dov (SPCC), phaj kub dov (SHCC), phaj galvanized (SECC, SGCC), tooj liab (CU) tooj dag, tooj liab liab, tooj liab beryllium, phaj txhuas (6061, 5052) 1010, 1060, 6063, duralumin, thiab lwm yam), cov ntaub ntawv txhuas, hlau tsis xeb (daim iav nto, txhuam nto, matte nto), nyob ntawm lub luag haujlwm ntawm cov khoom, kev xaiv cov ntaub ntawv sib txawv, thiab feem ntau yuav tsum tau xav txog los ntawm kev siv cov khoom thiab tus nqi.

(1) Cov ntawv SPCC txias dov, feem ntau yog siv rau electroplating thiab ci cov khoom siv varnish, tus nqi qis, yooj yim rau cov duab, thiab cov khoom siv tuab ≤ 3.2 hli.

(2) Daim ntawv kub dov SHCC, cov khoom siv T≥3.0mm, kuj siv electroplating, pleev xim rau qhov chaw, tus nqi qis, tab sis nyuaj rau tsim, feem ntau yog qhov chaw tiaj tus.

(3) SECC, SGCC galvanized sheet. SECC electrolytic board muab faib ua N khoom thiab P khoom. N khoom feem ntau yog siv rau kev kho saum npoo thiab tus nqi siab. P khoom siv rau cov khoom txau.

(4) Tooj liab, feem ntau yog siv cov khoom siv hluav taws xob, kev kho qhov chaw yog nickel plating, chrome plating, lossis tsis kho, tus nqi siab.

(5) Phaj txhuas, feem ntau siv cov chromate nto (J11-A), oxidation (conductive oxidation, tshuaj oxidation), tus nqi siab, nyiaj plating, nickel plating.

(6) Cov ntaub ntawv txhuas, cov ntaub ntawv uas muaj cov qauv sib tshooj nyuaj siv dav hauv ntau lub thawv me. Kev kho qhov chaw zoo ib yam li cov phaj txhuas.

(7) Cov hlau tsis xeb, nws feem ntau yog siv yam tsis muaj kev kho saum npoo, thiab tus nqi siab.

Cov ntaub ntawv siv feem ntau

- Cov ntawv hlau galvanized SECC

Lub substrate ntawm SECC yog cov hlau dov txias ib txwm, uas dhau los ua cov khoom electro-galvanized tom qab degreasing, pickling, electroplating thiab ntau yam kev kho mob tom qab ntawm cov kab ntau lawm electro-galvanizing tas mus li. SECC tsis yog tsuas yog muaj cov khoom siv kho tshuab thiab kev ua haujlwm zoo ib yam li cov hlau dov txias ib txwm, tab sis kuj muaj kev tiv thaiv corrosion zoo dua thiab zoo nkauj. Nws muaj kev sib tw heev thiab hloov tau hauv kev lag luam ntawm cov khoom siv hluav taws xob, cov khoom siv hauv tsev thiab rooj tog. Piv txwv li, SECC feem ntau siv rau hauv cov thawv computer.

2. Daim ntawv txias txias SPCC

SPCC yog hais txog kev dov cov hlau ingots tas mus li los ntawm cov tshuab dov txias mus rau hauv cov hlau coils lossis cov ntawv tuab uas xav tau. Tsis muaj kev tiv thaiv ntawm qhov chaw ntawm SPCC, thiab nws yooj yim oxidized thaum raug rau huab cua, tshwj xeeb tshaj yog nyob rau hauv ib puag ncig noo noo, qhov ceev oxidation yog ceev, thiab cov xeb liab tsaus tshwm sim. Qhov chaw yuav tsum tau pleev xim, electroplated lossis lwm yam kev tiv thaiv thaum siv. SPCC yog hais txog kev dov cov hlau ingots tas mus li los ntawm cov tshuab dov txias mus rau hauv cov hlau coils lossis cov ntawv tuab uas xav tau. Tsis muaj kev tiv thaiv ntawm qhov chaw ntawm SPCC, thiab nws yooj yim oxidized thaum raug rau huab cua, tshwj xeeb tshaj yog nyob rau hauv ib puag ncig noo noo, qhov ceev oxidation yog ceev, thiab cov xeb liab tsaus tshwm sim. Qhov chaw yuav tsum tau pleev xim, electroplated lossis lwm yam kev tiv thaiv thaum siv.

3. Cov ntawv hlau kub-dip galvanized SGCC

Cov hlau galvanized kub-dip yog hais txog cov khoom tiav ib nrab tom qab kub-dov thiab pickling lossis txias-dov, uas yog ntxuav thiab txuas ntxiv rau hauv lub dab dej zinc molten ntawm qhov kub ntawm kwv yees li 460 ° C, yog li ntawd cov ntawv hlau yog coated nrog ib txheej zinc thiab tom qab ntawd quenched thiab tempered SGCC khoom nyuaj dua li SECC khoom, muaj ductility tsis zoo (tsis txhob kos duab tob), txheej zinc tuab dua, thiab weldability tsis zoo.

4. Cov hlau tsis xeb SUS304

Yog ib qho ntawm cov hlau tsis xeb uas siv dav tshaj plaws. Vim nws muaj Ni (nickel), nws muaj kev tiv taus xeb thiab kub zoo dua li Cr (chromium) hlau. Nws muaj cov khoom siv kho tshuab zoo heev, tsis muaj qhov tshwm sim ntawm kev kho cua sov, thiab tsis muaj elasticity.

5. Cov hlau tsis xeb SUS301

Cov ntsiab lus ntawm Cr (chromium) qis dua li ntawm SUS304, thiab qhov tsis kam rau corrosion tsis zoo. Txawm li cas los xij, nws tuaj yeem tau txais lub zog tensile zoo thiab qhov nyuaj hauv kev stamping tom qab ua haujlwm txias, thiab muaj elasticity zoo. Nws feem ntau yog siv rau cov shrapnel springs thiab anti-EMI.

Kev tshuaj xyuas kos duab

Yuav kom sau tau cov txheej txheem ntawm ib feem, peb yuav tsum xub paub txog ntau yam kev cai ntawm daim duab kos; kev tshuaj xyuas daim duab kos yog qhov txuas tseem ceeb tshaj plaws hauv kev sau cov txheej txheem ntawm ib feem.

(1) Xyuas seb cov duab kos puas tiav.

(2) Kev sib raug zoo ntawm daim duab kos thiab qhov pom, seb daim ntawv lo puas meej, tiav, thiab chav ntsuas ntawm qhov ntev.

(3) Kev sib raug zoo ntawm kev sib dhos, qhov tseem ceeb ntawm cov kev cai sib dhos.

(4) Qhov sib txawv ntawm cov qauv qub thiab cov qauv tshiab ntawm cov duab.

(5) Kev txhais cov duab ua lus txawv teb chaws.

(6) Kev hloov pauv ntawm cov lej hauv rooj.

(7) Cov lus tawm tswv yim thiab kev pov tseg ntawm cov teeb meem kos duab.

(8) Cov Khoom Siv.

(9) Cov kev cai zoo thiab cov txheej txheem yuav tsum tau ua.

(10) Daim ntawv tso tawm ntawm cov duab kos yuav tsum tau muab luam tawm nrog lub foob tswj xyuas zoo.

Cov kev ceev faj

Daim duab pom dav dua yog daim phiaj xwm (2D) raws li daim duab kos (3D).

(1) Txoj kev nthuav dav yuav tsum tsim nyog, thiab nws yuav tsum yooj yim rau kev txuag cov ntaub ntawv thiab kev ua tiav.

(2) Xaiv qhov sib txawv thiab txoj kev ntug kom tsim nyog, T = 2.0, qhov sib txawv yog 0.2, T = 2-3, qhov sib txawv yog 0.5, thiab txoj kev ntug siv cov sab ntev thiab sab luv (qhov rooj vaj huam sib luag).

(3) Kev xav txog qhov ntev ntawm kev kam rau siab: qhov sib txawv tsis zoo mus txog qhov kawg, qhov sib txawv zoo mus ib nrab; qhov loj ntawm qhov: qhov sib txawv zoo mus txog qhov kawg, qhov sib txawv tsis zoo mus ib nrab.

(4) Kev taw qhia ntawm Burr.

(5) Kos ib daim duab hla-seem hauv qhov kev taw qhia ntawm kev rho tawm, kev nias riveting, kev rhuav, kev xuas nrig ntaus cov ntsiab lus convex (pob), thiab lwm yam.

(6) Xyuas cov khoom siv thiab tuab ntawm lub rooj tsavxwm kom txog rau qhov tuab ntawm lub rooj tsavxwm.

(7) Rau cov ces kaum tshwj xeeb, lub vojvoog sab hauv ntawm lub kaum sab xis (feem ntau R = 0.5) yuav tsum tau khoov thiab nthuav tawm.

(8) Cov chaw uas muaj qhov yuam kev (zoo sib xws) yuav tsum tau hais txog.

(9) Yuav tsum ntxiv cov duab loj dua qhov twg muaj ntau qhov loj dua.

(10) Yuav tsum qhia thaj chaw uas yuav tsum tau tiv thaiv los ntawm kev txau tshuaj.

Cov txheej txheem tsim khoom

Raws li qhov sib txawv ntawm cov qauv ntawm cov hlau ntawv, cov txheej txheem ntws tuaj yeem sib txawv, tab sis tag nrho tsis pub tshaj cov ntsiab lus hauv qab no.

- Kev Txiav: Muaj ntau txoj kev txiav, feem ntau yog cov hauv qab no.

① Tshuab Txiav: Nws yog ib daim khoom siv yooj yim uas siv lub tshuab txiav los txiav cov strips. Nws feem ntau yog siv rau kev ua pwm thiab kev npaj tsim. Tus nqi qis, thiab qhov tseeb tsawg dua 0.2, tab sis nws tsuas yog tuaj yeem ua cov strips lossis blocks uas tsis muaj qhov thiab tsis muaj ces kaum.

②Punch: Nws siv lub punch los punch tawm cov khoom tiaj tiaj tom qab nthuav cov khoom ntawm lub phaj hauv ib lossis ntau kauj ruam los tsim ntau yam duab ntawm cov khoom siv. Nws qhov zoo yog luv sijhawm ua haujlwm, ua haujlwm tau zoo, raug siab, pheej yig, thiab nws tsim nyog rau kev tsim khoom loj. , Tab sis los tsim cov pwm.

③NC CNC blanking. Thaum NC blanking, koj yuav tsum sau ib qho CNC machining program ua ntej. Siv cov software programming los sau cov duab kos uas tsis tau nthuav tawm rau hauv ib qho program uas NC digital drawing processing tshuab tuaj yeem paub, yog li nws tuaj yeem punch txhua daim ntawm lub phaj ib kauj ruam zuj zus raws li cov programs no. Cov qauv yog ib daim tiaj tiaj, tab sis nws cov qauv raug cuam tshuam los ntawm cov qauv ntawm lub cuab yeej, tus nqi qis, thiab qhov tseeb yog 0.15.

④Kev txiav laser yog kev siv laser txiav los txiav cov qauv thiab cov duab ntawm lub phaj tiaj tiaj ntawm lub phaj tiaj tiaj loj. Lub laser program yuav tsum tau programmed zoo li NC txiav. Nws tuaj yeem thauj ntau yam duab nyuaj ntawm cov khoom tiaj tiaj nrog tus nqi siab thiab qis dua qhov tseeb. 0.1.

⑤ Tshuab sawing: Feem ntau siv cov txhuas profiles, cov raj square, cov raj kos duab, cov kab puag ncig, thiab lwm yam, nrog tus nqi qis thiab qhov tseeb qis.

2. Fitter: countersinking, tapping, reaming, drilling.

Lub kaum sab xis ntawm lub qhov (counterbore angle) feem ntau yog 120 ℃, siv rau rub cov rivets, thiab 90 ℃ siv rau cov ntsia hlau uas muaj qhov thiab cov qhov hauv qab uas muaj qhov rau cov qhov (tapping).

3. Flanging: Nws tseem hu ua qhov kos duab thiab qhov tig, uas yog kos ib lub qhov loj me ntsis rau ntawm lub qhov me me, thiab tom qab ntawd coj mus rhaub nws. Nws feem ntau yog ua tiav nrog cov hlau nyias nyias kom nce nws lub zog thiab tus lej ntawm cov xov. , Txhawm rau kom tsis txhob swb cov hniav, feem ntau siv rau cov phaj nyias nyias, ib txwm muaj flanging ntiav ncig lub qhov, qhov tuab yeej tsis hloov pauv, thiab qhov tuab raug tso cai kom nyias los ntawm 30-40%, 40-siab dua qhov siab flangeing ib txwm tuaj yeem tau txais. Rau qhov siab ntawm 60%, qhov siab tshaj plaws flangeing tuaj yeem tau txais thaum thinning yog 50%. Thaum lub phaj tuab loj dua, xws li 2.0, 2.5, thiab lwm yam, nws tuaj yeem coj mus rhaub ncaj qha.

4. Punch: Nws yog ib txoj kev ua haujlwm uas siv pwm tsim. Feem ntau, kev ua haujlwm punching suav nrog kev punching, txiav ces kaum, blanking, punching convex hull (bump), punching thiab tearing, punching, forming thiab lwm yam kev ua haujlwm. Kev ua haujlwm yuav tsum muaj cov txheej txheem ua haujlwm sib xws. Lub pwm yog siv los ua kom tiav cov haujlwm, xws li punching thiab blanking pwm, convex pwm, tearing pwm, punching pwm, tsim pwm, thiab lwm yam. Kev ua haujlwm feem ntau them sai sai rau qhov chaw thiab kev coj ua.

5. Kev siv lub tshuab riveting siab: Raws li peb lub tuam txhab, kev siv lub tshuab riveting siab feem ntau suav nrog kev siv lub tshuab riveting siab, ntsia hlau, thiab lwm yam. Kev ua haujlwm tiav los ntawm lub tshuab riveting siab hydraulic lossis lub tshuab xuas nrig ntaus, riveting lawv rau ntawm cov hlau ntawv, thiab txoj kev riveting, yuav tsum tau them sai sai rau kev taw qhia.

6. Kev Khoov: Kev khoov yog kev quav 2D tiaj tiaj ua 3D qhov chaw. Kev ua tiav yuav tsum tau ua tiav nrog lub txaj quav thiab cov pwm khoov sib xws, thiab nws kuj muaj qee qhov kev khoov. Lub hauv paus ntsiab lus yog tias qhov txiav tom ntej tsis cuam tshuam nrog thawj qhov quav, thiab kev cuam tshuam yuav tshwm sim tom qab quav.

Tus naj npawb ntawm cov kab txaij khoov yog 6 npaug ntawm qhov tuab ntawm lub phaj hauv qab T = 3.0 hli los xam qhov dav ntawm qhov zawj, xws li: T = 1.0, V = 6.0 F = 1.8, T = 1.2, V = 8, F = 2.2, T = 1.5, V = 10, F = 2.7, T = 2.0, V = 12, F = 4.0.

Kev faib tawm ntawm lub txaj pwm khoov, riam ncaj, scimitar (80 ℃, 30 ℃).

Muaj cov kab nrib pleb thaum lub phaj txhuas raug khoov. Qhov dav ntawm qhov tuag qis dua tuaj yeem nce ntxiv, thiab qhov tuag sab saud R tuaj yeem nce ntxiv (annealing tuaj yeem zam kev tawg).

Cov kev ceev faj thaum khoov: Ⅰ Kos duab, qhov tuab ntawm daim hlau thiab qhov ntau npaum li cas; Ⅱ kev taw qhia khoov; Ⅲ lub kaum sab xis khoov; Ⅳ qhov loj ntawm khoov; Ⅵ tsos, tsis pub muaj qhov nkhaus ntawm cov khoom siv electroplated chromed. Kev sib raug zoo ntawm kev khoov thiab kev nias riveting feem ntau yog thawj qhov kev nias riveting thiab tom qab ntawd khoov, tab sis qee cov ntaub ntawv yuav cuam tshuam rau qhov kev nias riveting, thiab tom qab ntawd nias ua ntej, thiab qee qhov xav tau kev khoov-siab riveting-tom qab ntawd khoov thiab lwm yam txheej txheem.

7. Vuam: Vuam txhais: Qhov kev ncua deb ntawm cov atoms thiab molecules ntawm cov khoom siv welded thiab Jingda lattice tsim ib qho tag nrho.

①Kev Faib Tawm: a Kev vuam sib xyaw: argon arc vuam, CO2 vuam, roj vuam, vuam tes. b Kev vuam siab: vuam qhov chaw, vuam pob tw, vuam pob. c Kev sib txhuam: vuam hluav taws xob chromium, hlau tooj liab.

② Txoj kev vuam: a. Siv roj CO2 los tiv thaiv kev vuam. b. Siv argon arc vuam. c. Siv qhov chaw vuam, thiab lwm yam. d. Siv neeg hlau vuam.

Kev xaiv txoj kev vuam yog raws li qhov xav tau tiag tiag thiab cov ntaub ntawv. Feem ntau, CO2 roj shielded vuam siv rau hlau phaj vuam; argon arc vuam siv rau stainless hlau thiab txhuas phaj vuam. Robot vuam tuaj yeem txuag tau sijhawm ua haujlwm thiab txhim kho kev ua haujlwm zoo. Thiab qhov zoo ntawm kev vuam, txo qhov siv zog ua haujlwm.

③ Lub cim vuam: Δ fillet vuam, Д, I hom vuam, V hom vuam, ib sab V hom vuam (V) V hom vuam nrog ntug blunt (V), qhov chaw vuam (O), ntsaws vuam lossis qhov vuam (∏), Crimp vuam (χ), ib sab V-puab vuam nrog ntug blunt (V), U-puab vuam nrog blunt, J-puab vuam nrog blunt, nraub qaum vuam, thiab txhua qhov vuam.

④ Cov xov hlau xub thiab cov khoom sib txuas.

⑤ Tsis muaj kev vuam thiab kev tiv thaiv.

Qhov chaw vuam: yog tias lub zog tsis txaus, cov pob tuaj yeem ua tau thiab thaj chaw vuam raug yuam

CO2 vuam: kev tsim khoom siab, kev siv hluav taws xob tsawg, tus nqi qis, muaj zog tiv taus xeb

Argon arc vuam: qhov tob melting ntiav, qeeb qeeb vuam ceev, qis efficiency, siab ntau lawm nqi, tungsten suav nrog qhov tsis xws luag, tab sis muaj qhov zoo ntawm qhov zoo vuam, thiab tuaj yeem vuam cov hlau tsis yog ferrous, xws li txhuas, tooj liab, magnesium, thiab lwm yam.

⑥ Vim li cas ho vuam tsis zoo: tsis npaj txhij ua ntej vuam, xav tau cov khoom siv ntxiv. Txhim kho cov txheej txheem rau cov jigs vuam tsis zoo. Cov txheej txheem vuam tsis zoo.

⑦ Txoj Kev Kho Qhov Kev Hloov Pauv ntawm Kev Vuam: Txoj Kev Kho Hluav Taws Xob. Txoj Kev Co. Txoj Kev Rauj. Txoj Kev Laus Dag.

lwm cov apps

Cov kauj ruam ua cov khoom ua hauv lub rooj cob qhia hlau yog: kev sim ua ntej, kev sim ua cov khoom thiab kev tsim khoom ntau ntau. Hauv cov kauj ruam sim ua cov khoom, nws yuav tsum sib txuas lus nrog cov neeg siv khoom raws sijhawm, thiab tom qab tau txais kev ntsuam xyuas ntawm cov txheej txheem sib xws, cov khoom tuaj yeem tsim tau ntau.

Kev siv tshuab laser drilling yog cov thev naus laus zis laser ua tau zoo tshaj plaws hauv kev siv tshuab laser ua cov khoom siv. Kev siv laser drilling hauv lub rooj cob qhia hlau feem ntau siv cov lasers pulsed, uas muaj lub zog ceev dua thiab lub sijhawm luv dua. Nws tuaj yeem ua cov qhov me me ntawm 1μm. Nws yog qhov tshwj xeeb tshaj yog rau kev ua cov qhov me me nrog lub kaum sab xis thiab cov khoom nyias nyias, thiab nws kuj tsim nyog rau kev ua lub zog thiab qhov nyuaj. Cov qhov me me sib sib zog nqus thiab cov qhov me me hauv cov khoom siab dua lossis ntau dua brittle thiab softer.

Lub laser tuaj yeem ua tiav qhov kev khawb ntawm cov khoom siv combustor ntawm lub cav roj turbine, thiab qhov cuam tshuam drilling tuaj yeem ua tiav qhov kev taw qhia peb-seem, thiab tus lej tuaj yeem ncav cuag txhiab. Cov ntaub ntawv perforated suav nrog stainless hlau, nickel-chromium-iron alloys, thiab HASTELLOY-based alloys. Lub tshuab laser drilling tsis cuam tshuam los ntawm cov khoom siv kho tshuab ntawm cov khoom siv, thiab nws yooj yim dua los ua tiav automation.

Nrog rau kev txhim kho ntawm cov thev naus laus zis laser drilling, lub tshuab txiav laser tau ua tiav kev ua haujlwm tsis siv neeg. Daim ntawv thov hauv kev lag luam hlau ntawv tau hloov pauv txoj kev ua cov txheej txheem ntawm cov thev naus laus zis hlau ntawv ib txwm muaj, ua tiav kev ua haujlwm tsis muaj neeg tsav, txhim kho kev tsim khoom zoo heev, thiab ua tiav tag nrho cov txheej txheem. Kev ua haujlwm tsis siv neeg tau txhawb nqa kev txhim kho ntawm kev lag luam hlau ntawv, thiab tau txhim kho cov nyhuv xuas nrig mus rau qib siab dua, thiab cov nyhuv ua tiav zoo kawg nkaus.

Lub sijhawm tshaj tawm: Tsib Hlis-27-2021