Sarrafa takardar ƙarfe

Sarrafa takardar ƙarfe fasaha ce mai cibiya da masu fasaha ke buƙatar fahimta, kuma muhimmin tsari ne a cikin ƙirƙirar samfurin takardar ƙarfe. Sarrafa takardar ƙarfe ya haɗa da yankewa na gargajiya, ɓoyewa, lanƙwasawa da ƙirƙirar hanyoyin da sigogin sarrafawa, da kuma sigogin tsarin sanyaya da sanyi, ƙa'idodi daban-daban na aiki da hanyoyin aiki, da sabuwar fasahar sanya tambari da sabuwar fasaha. Sarrafa takardar ƙarfe ana kiransa sarrafa takardar ƙarfe.

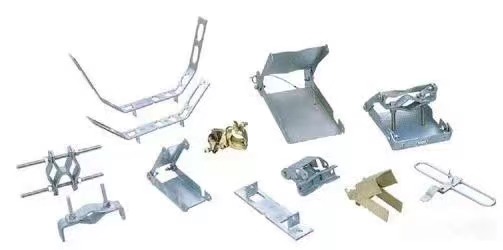

Ana kiran sarrafa ƙarfen sheet metal processing. Musamman, misali, amfani da faranti don yin bututun hayaki, ganga na ƙarfe, tankunan mai, tankunan mai, bututun iska, gwiwar hannu, murabba'ai, mazurari, da sauransu. Manyan hanyoyin sun haɗa da aski, lanƙwasawa, lanƙwasawa, ƙirƙirawa, walda, riveting, da sauransu. Wasu ilimin lissafi. Sassan ƙarfe sheet metal slimmer stools ne na ƙarfe sheet, wato, sassan da za a iya sarrafa su ta hanyar buga tambari, lanƙwasawa, shimfiɗawa da sauran hanyoyi. Ma'anar gabaɗaya wani ɓangare ne mai kauri akai-akai yayin sarrafawa. Ya yi daidai da siminti, ƙirƙira, sassan injina, da sauransu.

Zaɓin kayan aiki

Kayan da ake amfani da su a fannin sarrafa ƙarfe sune farantin da aka yi da sanyi (SPCC), farantin da aka yi da zafi (SHCC), farantin galvanized (SECC, SGCC), tagulla na jan ƙarfe (CU), jan ƙarfe, jan ƙarfe na beryllium, farantin aluminum (6061, 5052) 1010, 1060, 6063, duralumin, da sauransu), bayanan aluminum, bakin ƙarfe (surface madubi, surface mai gogewa, surface mai matte), ya danganta da rawar da samfurin ke takawa, zaɓin kayan ya bambanta, kuma gabaɗaya ana buƙatar la'akari da amfani da samfurin da farashinsa.

(1) Takardar SPCC mai sanyi da aka yi amfani da ita, wacce aka fi amfani da ita wajen yin amfani da kayan lantarki da kuma yin burodi, mai rahusa, mai sauƙin siffantawa, da kuma kauri na kayan ≤ 3.2mm.

(2) Takardar SHCC mai zafi, kayan T≥3.0mm, tana amfani da fenti mai laushi, sassa masu laushi, amma tana da wahalar samarwa, galibi sassa masu faɗi.

(3) Takardar galvanized ta SECC, SGCC. An raba allon lantarki na SECC zuwa kayan N da kayan P. Ana amfani da kayan N galibi don maganin saman da tsada mai yawa. Ana amfani da kayan P don sassan da aka fesa.

(4) Tagulla, galibi ana amfani da shi wajen sarrafa kayan aiki, maganin saman shine nickel plating, chrome plating, ko babu magani, farashi mai tsada.

(5) Farantin aluminum, gabaɗaya yana amfani da saman chromate (J11-A), oxidation (mai haifar da oxidation, sinadarai), farashi mai tsada, plating na azurfa, nickel plating.

(6) Bayanan aluminum, kayan da ke da tsarin giciye mai rikitarwa ana amfani da su sosai a cikin ƙananan akwatuna daban-daban. Maganin saman iri ɗaya ne da farantin aluminum.

(7) Bakin karfe, galibi ana amfani da shi ba tare da wani magani na saman ba, kuma farashin yana da yawa.

Kayan da aka fi amfani da su

- Takardar ƙarfe ta galvanized SECC

Tsarin SECC shine na'urar ƙarfe mai sanyi ta yau da kullun, wacce ke zama samfurin lantarki bayan an cire mai, an cire ciyayi, an cire electroplating da kuma hanyoyin bayan magani daban-daban akan layin samar da electro-galvanizing mai ci gaba. SECC ba wai kawai tana da halayen injiniya da kuma irin wannan ikon sarrafawa na takardar ƙarfe mai sanyi gaba ɗaya ba, har ma tana da juriyar tsatsa da kuma kyawun ado. Yana da gasa sosai kuma ana iya maye gurbinsa a kasuwar kayayyakin lantarki, kayan gida da kayan daki. Misali, ana amfani da SECC akai-akai a cikin shari'o'in kwamfuta.

2. Takardar SPCC mai sanyi ta yau da kullun

SPCC tana nufin ci gaba da birgima ingots na ƙarfe ta cikin injin niƙa mai sanyi zuwa cikin na'urorin ƙarfe ko zanen gado masu kauri da ake buƙata. Babu kariya a saman SPCC, kuma ana iya yin oxidize cikin sauƙi lokacin da aka fallasa shi ga iska, musamman a cikin yanayi mai danshi, saurin oxidation yana ƙaruwa, kuma tsatsa mai duhu ja ta bayyana. Ya kamata a fenti saman, a yi amfani da electroplated ko wani kariya lokacin da ake amfani da shi. SPCC tana nufin ci gaba da birgima ingots na ƙarfe ta cikin injin niƙa mai sanyi zuwa cikin na'urorin ƙarfe ko zanen gado masu kauri da ake buƙata. Babu kariya a saman SPCC, kuma ana iya oxidize shi cikin sauƙi lokacin da aka fallasa shi ga iska, musamman a cikin yanayi mai danshi, saurin oxidation yana ƙaruwa, kuma ja mai duhu tsatsa ta bayyana. Ya kamata a fenti saman, a yi amfani da electroplated ko wani kariya lokacin da ake amfani da shi.

3. Zafi-tsoma galvanized karfe takardar SGCC

Na'urar ƙarfe mai kauri da aka yi da zafi tana nufin samfurin da aka gama bayan an yi birgima da yayyanka ko kuma an yi birgima da sanyi, wanda ake wankewa kuma ana ci gaba da nutsar da shi a cikin baho mai narke zinc a zafin jiki na kimanin 460°C, don haka takardar ƙarfe ta shafa da layin zinc sannan a kashe ta kuma a sanyaya ta SGCC ta fi kayan SECC wahala, tana da ƙarancin sassauci (guje wa ƙirar zane mai zurfi), layin zinc mai kauri, da kuma rashin iya walda.

4. Bakin ƙarfe SUS304

Ɗaya daga cikin ƙarfen bakin ƙarfe da aka fi amfani da shi. Saboda yana ɗauke da Ni (nickel), yana da juriyar tsatsa da kuma juriyar zafi fiye da ƙarfe Cr (chromium). Yana da kyawawan halaye na injiniya, babu wani abu mai taurarewa na maganin zafi, kuma babu sassauci.

5. Bakin ƙarfe SUS301

Abun da ke cikin Cr (chromium) ya yi ƙasa da na SUS304, kuma juriyar tsatsa ba ta da kyau. Duk da haka, yana iya samun ƙarfi mai kyau da tauri yayin da ake buga shi bayan sanyi, kuma yana da kyakkyawan sassauci. Ana amfani da shi galibi don maɓuɓɓugan busassun kaya da kuma hana EMI.

Sharhin zane

Domin tattara tsarin aiwatar da wani ɓangare, dole ne mu fara sanin buƙatun fasaha daban-daban na zanen ɓangaren; bitar zane ita ce hanya mafi mahimmanci wajen tattara tsarin aiwatar da ɓangaren.

(1) Duba ko zane-zanen sun cika.

(2) Alaƙar da ke tsakanin zane da kallo, ko lakabin a bayyane yake, cikakke ne, da kuma naúrar girma.

(3) Hulɗar taro, muhimman ma'auni na buƙatun taro.

(4) Bambanci tsakanin tsoffin sigar zane-zane da sabbin sigar.

(5) Fassarar hotuna a cikin harsunan waje.

(6) Canza lambobin tebur.

(7) Ra'ayoyi da kuma kawar da matsalolin zane.

(8) Kayan aiki.

(9) Bukatun inganci da buƙatun tsari.

(10) Dole ne a buga zane-zanen da hatimin kula da inganci a hukumance.

Matakan kariya

Faɗaɗar ra'ayi shine tsarin ra'ayi (2D) bisa ga zane na ɓangaren (3D).

(1) Hanyar faɗaɗawa ya kamata ta dace, kuma ya kamata ta kasance mai dacewa don adana kayan aiki da iya sarrafa su.

(2) Zaɓi hanyar gibin da gefuna daidai gwargwado, T=2.0, gibin shine 0.2, T=2-3, gibin shine 0.5, kuma hanyar gefuna tana amfani da dogayen gefuna da gajerun gefuna (ayyukan ƙofa).

(3) La'akari mai kyau game da ma'aunin haƙuri: bambanci mara kyau yana zuwa ƙarshe, bambanci mai kyau yana zuwa rabi; girman rami: bambanci mai kyau yana zuwa ƙarshe, bambanci mara kyau yana zuwa rabi.

(4) Alkiblar Burr.

(5) Zana wani ra'ayi na giciye a gefen cirewa, toshewar matsi, yagewa, huda wuraren da ke kewaye (kunshin), da sauransu.

(6) Duba kayan da kauri na allon zuwa ga juriyar kauri na allon.

(7) Ga kusurwoyi na musamman, radius na ciki na kusurwar lanƙwasa (gabaɗaya R=0.5) yana buƙatar a lanƙwasa shi kuma a buɗe shi.

(8) Ya kamata a haskaka wuraren da ke fuskantar kurakurai (irin wannan rashin daidaito).

(9) Ya kamata a ƙara manyan hotuna inda akwai ƙarin girma.

(10) Dole ne a nuna yankin da za a kare ta hanyar feshi.

Tsarin masana'antu

Dangane da bambancin tsarin sassan ƙarfe na takarda, kwararar tsari na iya zama daban, amma jimlar ba ta wuce maki masu zuwa ba.

- Yankewa: Akwai hanyoyi daban-daban na yankewa, galibi waɗannan hanyoyin.

①Injin aski: Wani abu ne mai sauƙi wanda ke amfani da injin aski don yanke tsiri. Ana amfani da shi galibi don shirya mold da kuma shirya shi. Kudin yana da ƙasa, kuma daidaiton bai wuce 0.2 ba, amma yana iya sarrafa tsiri ko tubalan ne kawai ba tare da ramuka ko kusurwoyi ba.

②Punch: Yana amfani da naushi don fitar da sassan da ke kwance bayan buɗe sassan da ke kan farantin a matakai ɗaya ko fiye don samar da siffofi daban-daban na kayan aiki. Amfaninsa sune gajerun sa'o'i na aiki, inganci mai yawa, daidaito mai yawa, ƙarancin farashi, kuma ya dace da samar da kayayyaki da yawa. Amma don tsara ƙirar.

③NC CNC blanking. Lokacin da NC blanking yake, dole ne ka fara rubuta shirin injin CNC. Yi amfani da manhajar shirye-shirye don rubuta hoton da aka zana a cikin wani shiri wanda injin sarrafa zane na dijital na NC zai iya gane shi, ta yadda zai iya buga kowanne a kan farantin mataki-mataki bisa ga waɗannan shirye-shiryen. Tsarin yanki ne mai faɗi, amma tsarinsa yana shafar tsarin kayan aikin, farashin yana da ƙasa, kuma daidaito shine 0.15.

④Yankewar Laser shine amfani da yanke laser don yanke tsari da siffar farantin lebur akan babban farantin lebur. Shirin laser yana buƙatar a tsara shi kamar yankewar NC. Yana iya ɗora siffofi daban-daban masu rikitarwa na sassa masu lebur tare da farashi mai yawa da ƙarancin daidaito. 0.1.

⑤Na'urar sawing: A mafi yawan lokuta ana amfani da bayanan aluminum, bututun murabba'i, bututun zane, sandunan zagaye, da sauransu, tare da ƙarancin farashi da ƙarancin daidaito.

2. Mai gyarawa: nutsewa, taɓawa, sake yin gyaran fuska, haƙa rami.

Kusurwar counterbore gabaɗaya tana da 120℃, ana amfani da ita don jan rivets, kuma ana amfani da ita 90℃ don sukurori masu ɓoyewa da kuma taɓa ramukan ƙasan inci.

3. Faɗin Rami: Ana kuma kiransa da zana rami da jujjuya rami, wanda shine zana rami mai ɗan girma a kan ƙaramin ramin tushe, sannan a taɓa shi. Ana sarrafa shi da ƙarfe mai siriri don ƙara ƙarfinsa da adadin zare. , Don guje wa zamewar haƙora, wanda galibi ana amfani da shi don kauri farantin siriri, flange na yau da kullun a kusa da ramin, kauri ba ya canzawa, kuma ana barin kauri ya zama siriri da kashi 30-40%, ana iya samun tsayin flange na yau da kullun sama da 40. Don tsayin 60%, ana iya samun matsakaicin tsayin flange lokacin da sirara ta kai 50%. Lokacin da kauri na farantin ya fi girma, kamar 2.0, 2.5, da sauransu, ana iya taɓa shi kai tsaye.

4. Naushi: Tsarin sarrafawa ne wanda ke amfani da ƙirƙirar mold. Gabaɗaya, sarrafa naushi ya haɗa da naushi, yanke kusurwa, faɗuwa, huda ƙusoshi masu lanƙwasa (bump), huda da tsagewa, hudawa, ƙirƙira da sauran hanyoyin sarrafawa. Ana buƙatar sarrafa naushi ya zama yana da hanyoyin sarrafawa masu dacewa. Ana amfani da naushi don kammala ayyukan, kamar hudawa da faɗuwa molds, ƙusoshin masu lanƙwasa, tsage molds, huda molds, ƙirƙirar molds, da sauransu. Aikin galibi yana mai da hankali kan matsayi da alkibla.

5. Rike matsi: Dangane da kamfaninmu, rike matsi ya ƙunshi goro mai rike matsi, sukurori, da sauransu. Ana kammala aikin ta hanyar injin rike matsi na hydraulic ko injin hudawa, a rike su zuwa sassan ƙarfe na sheet, da kuma rike Way, ana buƙatar kulawa da alkibla.

6. Lankwasawa: Lankwasawa ita ce a naɗe sassan 2D masu faɗi zuwa sassa 3D. Ana buƙatar a kammala aikin da gadon naɗewa da kuma molds masu lankwasawa masu dacewa, kuma yana da wani tsari na lankwasawa. Ka'idar ita ce yanke na gaba ba ya tsoma baki ga naɗewa na farko, kuma tsangwama za ta faru bayan naɗewa.

Adadin layukan lanƙwasa ya ninka kauri na farantin da ke ƙasa da T=3.0mm sau 6 don ƙididdige faɗin ramin, kamar: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V=10, F=2.7, T=2.0, V=12, F=4.0.

Rarraba kayan gado mai lanƙwasa, wuka madaidaiciya, scimitar (80 ℃, 30 ℃).

Akwai tsagewa idan aka lanƙwasa farantin aluminum. Ana iya ƙara faɗin ramin ƙasan ramin die, kuma ana iya ƙara girman die R na sama (annealing na iya guje wa tsagewa).

Gargaɗi yayin lanƙwasawa: Ⅰ Zane, kauri da adadin farantin da ake buƙata; Ⅱ alkiblar lanƙwasa; Ⅲ kusurwar lanƙwasa; Ⅳ girman lanƙwasawa; Ⅵ bayyanar, ba a yarda da ƙuraje a kan kayan chromed mai haske ba. Alaƙar da ke tsakanin lanƙwasawa da tsarin riveting na matsi gabaɗaya shine riveting na matsi na farko sannan lanƙwasawa, amma wasu kayan zasu tsoma baki tare da riveting na matsi, sannan a danna farko, wasu kuma suna buƙatar lanƙwasawa-riveting na matsi-sannan lanƙwasawa da sauran hanyoyin.

7. Walda: Ma'anar walda: Nisa tsakanin kwayoyin halitta da kwayoyin halitta na kayan da aka haɗa da layin Jingda sun zama cikakke.

① Rarrabawa: a Haɗa walda: argon arc walda, CO2 walda, gas walda, walda da hannu. b Walda matsi: walda tabo, walda butt, walda ta bump. c Brazing: walda chromium na lantarki, waya ta jan ƙarfe.

② Hanyar walda: walda mai kariya daga iskar CO2. b walda mai kauri ta Argon. c Walda mai tabo, da sauransu. d Walda mai robot.

Zaɓin hanyar walda ya dogara ne akan ainihin buƙatu da kayan aiki. Gabaɗaya, walda mai kariya daga iskar gas ta CO2 ana amfani da ita don walda farantin ƙarfe; walda argon arc ana amfani da ita don walda farantin bakin ƙarfe da aluminum. Walda robot na iya adana sa'o'i na aiki da inganta ingancin aiki. Kuma ingancin walda yana rage ƙarfin aiki.

③ Alamar walda: ③ walda fillet, �, walda nau'in I, walda nau'in V, walda nau'in V guda ɗaya (V) walda nau'in V tare da gefen blunt (V), walda tabo (O), walda ko walda rami (∏), walda mai kauri (χ), walda mai siffar V guda ɗaya tare da gefen blunt (V), walda mai siffar U tare da blunt, walda mai siffar J tare da blunt, walda murfin baya, da kowane walda.

④ Wayoyin kibiya da masu haɗawa.

⑤ Rashin walda da matakan kariya.

Walda tabo: idan ƙarfin bai isa ba, ana iya yin ƙusoshi kuma an sanya yankin walda

Walda ta CO2: yawan aiki mai yawa, ƙarancin amfani da makamashi, ƙarancin farashi, juriyar tsatsa mai ƙarfi

Walda ta Argon arc: zurfin narkewa mai zurfi, saurin walda a hankali, ƙarancin inganci, farashin samarwa mai yawa, lahani a cikin haɗa tungsten, amma yana da fa'idar ingancin walda mai kyau, kuma yana iya walda ƙarfe marasa ƙarfe, kamar aluminum, jan ƙarfe, magnesium, da sauransu.

⑥ Dalilan nakasar walda: rashin shiri kafin walda, ana buƙatar ƙarin kayan aiki. Inganta tsari don rashin kyawun jigs na walda. Jerin walda ba shi da kyau.

⑦ Hanyar Gyaran Nakasa ta Walda: Hanyar Gyaran Wuta. Hanyar Girgizawa. Hanyar Hammering. Hanyar tsufa ta wucin gadi.

wasu manhajoji

Matakan sarrafa sassan sarrafa kayayyaki a cikin bitar ƙarfe sune: gwajin samfura kafin gwaji, gwajin sarrafa samfura da kuma samar da samfura. A cikin matakin gwajin sarrafa samfura, ya kamata ya yi magana da abokan ciniki akan lokaci, kuma bayan samun kimantawar sarrafa da ta dace, ana iya samar da samfurin da yawa.

Fasahar haƙa Laser ita ce fasahar laser ta farko a fasahar sarrafa kayan laser. Haƙa Laser a cikin bitar ƙarfe mai sheet yawanci yana amfani da lasers masu pulsed, waɗanda ke da yawan kuzari mafi girma da gajeriyar lokaci. Yana iya sarrafa ƙananan ramuka na 1μm. Ya dace musamman don sarrafa ƙananan ramuka tare da wani kusurwa da sirara abu, kuma ya dace da sarrafa ƙarfi da tauri. Ƙananan ramuka masu zurfi da ƙananan ramuka a cikin sassan kayan da suka fi girma ko mafi rauni da laushi.

Laser ɗin zai iya gano haƙa sassan injin turbin gas, kuma tasirin haƙa zai iya cimma alkiblar girma uku, kuma adadin zai iya kaiwa dubbai. Kayayyakin da aka huda sun haɗa da bakin ƙarfe, gami da nickel-chromium-iron, da kuma gami da HASTELLOY. Fasahar haƙa laser ba ta shafar halayen injiniya na kayan ba, kuma yana da sauƙin aiwatarwa ta atomatik.

Tare da haɓaka fasahar haƙa laser, injin yanke laser ya fara aiki ta atomatik. Aikace-aikacen a masana'antar ƙarfe na sheet metal ya canza hanyar sarrafa fasahar ƙarfe na gargajiya, ya sami aikin ba tare da matuƙi ba, ya inganta ingantaccen samarwa sosai, kuma ya cimma dukkan tsarin. Aikin atomatik ya haɓaka ci gaban tattalin arzikin ƙarfe na sheet metal, kuma ya inganta tasirin bugun ƙarfe zuwa mafi girma, kuma tasirin sarrafawa abin mamaki ne.

Lokacin Saƙo: Mayu-27-2021