Ukucubungula isinyithi sephepha

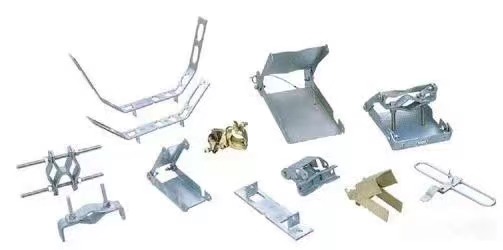

Ukucubungula isinyithi sephepha yiteknoloji yehabhu ekufuneka iingcali zesinyithi zephepha ziyiqonde, kwaye ikwayinkqubo ebalulekileyo ekwenzeni imveliso yesinyithi sephepha. Ukucubungula isinyithi sephepha kuquka iindlela zemveli zokusika, ukuvala, ukugoba kunye nokwenza kunye neeparamitha zenkqubo, kunye neendlela ezahlukeneyo zesakhiwo sedayisi yokunyathela kunye nenkqubo, imigaqo eyahlukeneyo yokusebenza kwezixhobo kunye neendlela zokusebenza, kunye netekhnoloji entsha yokunyathela kunye netekhnoloji entsha. Ukucubungula isinyithi sephepha lenxalenye kubizwa ngokuba yi-sheet metal processing.

Ukucubungula isinyithi kuthiwa kukucubungula isinyithi. Ngokukodwa, umzekelo, ukusetyenziswa kweepleyiti ukwenza iitshimini, iibhareli zesinyithi, iitanki zepetroli, iitanki zeoyile, iipayipi zomoya, iingqiniba, iingqiniba, izikwere, ii-funnels, njl. Iinkqubo eziphambili ziquka ukucheba, ukugoba, ukugoba, ukwenza, ukuwelda, ukugoba, njl. Ulwazi oluthile lwejometri. Iinxalenye zesinyithi zesinyithi ziindawo ezincinci zesinyithi, oko kukuthi, iindawo ezinokucutshungulwa ngokunyathela, ukugoba, ukolula nezinye iindlela. Inkcazo ngokubanzi yinxalenye enobukhulu obungaguqukiyo ngexesha lokucubungula. Ihambelana nokuphoswa, ukugqunywa, iindawo zomatshini, njl.

Ukukhetha izinto

Izinto ezisetyenziswa ngokubanzi ekucutshungulweni kwesinyithi sephepha yipleyiti eqengqelekayo ebandayo (SPCC), ipleyiti eqengqelekayo eshushu (SHCC), ipleyiti yegalvanized (SECC, SGCC), ithusi lekopolo (CU), ithusi elibomvu, ithusi leberyllium, ipleyiti yealuminiyam (6061, 5052) 1010, 1060, 6063, iduralumin, njl.njl.), iiprofayili zealuminiyam, intsimbi engatyiwayo (umphezulu wesipili, umphezulu oxutyiweyo, umphezulu ongamatte), kuxhomekeke kwindima yemveliso, ukhetho lwezinto zahlukile, kwaye ngokubanzi kufuneka luqwalaselwe kusetyenziso lwemveliso kunye nexabiso layo.

(1) I-SPCC yeshiti eqengqelekayo ebandayo, esetyenziselwa ikakhulu ukuplata nge-electroplating kunye nokubhaka iindawo zevarnish, ixabiso layo liphantsi, kulula ukuyila, kunye nobukhulu bezinto ezisetyenzisiweyo ≤ 3.2mm.

(2) Ishidi eligoqekileyo elishushu i-SHCC, eliyi-T≥3.0mm, likwasebenzisa i-electroplating, iindawo zepeyinti, ezingabizi kakhulu, kodwa kunzima ukuzenza, ikakhulu iindawo ezithe tyaba.

(3) I-SECC, iphepha le-galvanized le-SGCC. Ibhodi ye-electrolytic ye-SECC yahlulwe yaba zizinto ze-N kunye nezinto ze-P. Izinto ze-N zisetyenziselwa kakhulu unyango lomphezulu kwaye zibiza kakhulu. Izinto ze-P zisetyenziselwa iindawo ezitshiziweyo.

(4) I-Copper, esetyenziswa kakhulu kwizinto eziqhubayo, unyango lomphezulu luyi-nickel plating, i-chrome plating, okanye akukho nyango, ixabiso liphezulu.

(5) Ipleyiti ye-aluminiyam, ngokubanzi isebenzisa i-surface chromate (J11-A), i-oxidation (i-conductive oxidation, i-chemical oxidation), ixabiso eliphezulu, i-silver plating, i-nickel plating.

(6) Iiprofayili ze-aluminiyam, izixhobo ezinezakhiwo ezintsonkothileyo zecandelo elinqamlezileyo zisetyenziswa kakhulu kwiibhokisi ezahlukeneyo. Unyango lomphezulu lufana nepleyiti ye-aluminiyam.

(7) Intsimbi engagqwaliyo, isetyenziswa kakhulu ngaphandle kokulungiswa komphezulu, kwaye ixabiso liphezulu.

Izixhobo ezisetyenziswa rhoqo

- Ishidi lesinyithi eligayiweyo le-SECC

Isiseko se-SECC yi-coil yentsimbi eqhelekileyo eqengqelekayo ebandayo, eba yimveliso eyenziwe nge-electro-galvanized emva kokususa amafutha, ukuqhola, ukufakelwa nge-electroplating kunye neenkqubo ezahlukeneyo emva konyango kumgca wemveliso eqhubekayo ye-electro-galvanizing. I-SECC ayinazo nje kuphela iimpawu zoomatshini kunye nokuqhubekeka okufanayo kweshiti yentsimbi eqhelekileyo eqengqelekayo ebandayo, kodwa ikwanokumelana nokugqwala okuphezulu kunye nenkangeleko yokuhombisa. Ikhuphisana kakhulu kwaye inokutshintshwa kwimarike yeemveliso ze-elektroniki, izixhobo zasekhaya kunye nefenitshala. Umzekelo, i-SECC isetyenziswa kakhulu kwiimeko zekhompyutha.

2. Iphepha eliqhelekileyo elibandayo eliqengqelekayo le-SPCC

I-SPCC ibhekisa ekuqengqelekeni okuqhubekayo kwee-ingots zentsimbi ngokusebenzisa ii-cold rolling mills ziye kwii-coil zentsimbi okanye amaphepha anobukhulu obufunekayo. Akukho khuseleko kumphezulu we-SPCC, kwaye kulula ukuyi-oxidation xa ivezwa emoyeni, ingakumbi kwindawo efumileyo, isantya soku-oxidation siyakhawuleza, kwaye kuvela umhlwa obomvu omnyama. Umphezulu kufuneka upeyintwe, ufakwe i-electroplated okanye olunye ukhuseleko xa usetyenziswa. I-SPCC ibhekisa ekuqengqelekeni okuqhubekayo kwee-ingots zentsimbi ngokusebenzisa ii-cold rolling mills ziye kwii-coil zentsimbi okanye amaphepha anobukhulu obufunekayo. Akukho khuseleko kumphezulu we-SPCC, kwaye kulula ukuyi-oxidation xa ivezwa emoyeni, ingakumbi kwindawo efumileyo, isantya soku-oxidation siyakhawuleza, kwaye kuvela umhlwa obomvu omnyama. Umphezulu kufuneka upeyintwe, ufakwe i-electroplated okanye olunye ukhuseleko xa usetyenziswa.

3. Ishidi lesinyithi elishushu neligqunyiweyo le-SGCC

I-coil yentsimbi egqunyiweyo eshushu ibhekisa kwimveliso egqityiweyo emva kokuqengqeleka nokucoca okanye ukuqengqeleka okubandayo, ehlanjwa kwaye ihlale intywiliselwa kwibhafu ye-zinc enyibilikisiweyo kubushushu obumalunga ne-460°C, ukuze ishidi lesinyithi ligqunywe ngomaleko we-zinc kwaye emva koko licinywe kwaye izinto ze-SGCC ezithambileyo zibe nzima kunezinto ze-SECC, zinobunzima obuphantsi (ziphephe uyilo lomzobo olunzulu), umaleko we-zinc otyebileyo, kwaye azikwazi ukudityaniswa kakuhle.

4. I-SUS304 yentsimbi engenasici

Enye yezona ntsimbi zingenasici ezisetyenziswa kakhulu. Ngenxa yokuba ineNi (nickel), inokumelana nokugqwala kunye nokumelana nobushushu okungcono kuneCr (chromium) steel. Ineempawu ezintle kakhulu zoomatshini, ayinanto yokuqinisa unyango lobushushu, kwaye ayinakuthamba.

5. Intsimbi engatyiwayo i-SUS301

Umxholo we-Cr (chromium) uphantsi kunowe-SUS304, kwaye ukumelana nokugqwala akukuhle. Nangona kunjalo, inokufumana amandla okutsalwa kunye nobunzima obuhle xa inyathelwa emva kokusebenza ngokubanda, kwaye inokuqina okuhle. Isetyenziswa kakhulu kwizipringi ze-shrapnel kunye ne-anti-EMI.

Uhlolo lomzobo

Ukuze siqokelele ukuhamba kwenkqubo yenxalenye, kufuneka siqale sazi iimfuno zobugcisa ezahlukeneyo zomzobo wenxalenye; uphononongo lomzobo lolona khonkco lubalulekileyo ekuqokeleleni ukuhamba kwenkqubo yenxalenye.

(1) Jonga ukuba imizobo igqityiwe na.

(2) Ubudlelwane phakathi komzobo kunye nombono, nokuba ileyibhile icacile, iphelele, kunye neyunithi yobukhulu.

(3) Ubudlelwane phakathi kwendibano, imilinganiselo ephambili yeemfuno zendibano.

(4) Umahluko phakathi kweenguqulelo ezindala nezintsha zemizobo.

(5) Ukuguqulelwa kwemifanekiso kwiilwimi zasemzini.

(6) Ukuguqulwa kweekhowudi zetafile.

(7) Ingxelo kunye nokusombulula iingxaki zokuzoba.

(8) Izinto ezisetyenzisiweyo.

(9) Iimfuno zomgangatho kunye neemfuno zenkqubo.

(10) Ukukhutshwa ngokusemthethweni kwemizobo kufuneka kugximfizwe ngetywina lokulawula umgangatho.

Ukulumkela

Umbono owandisiweyo ngumbono wesicwangciso (2D) osekelwe kumzobo wenxalenye (3D).

(1) Indlela yokwandisa kufuneka ifaneleke, kwaye kufuneka ibe lula ukugcina izixhobo kunye nokuqhubekeka kokusebenza.

(2) Khetha ngokufanelekileyo indlela yesithuba kunye nesiphelo, T=2.0, isithuba singu-0.2, T=2-3, isithuba singu-0.5, kwaye indlela yesiphelo isebenzisa amacala amade kunye namacala amafutshane (iiphaneli zomnyango).

(3) Ingqwalasela efanelekileyo yemilinganiselo yokunyamezelana: umahluko ongalunganga uya esiphelweni, umahluko olungileyo uya esiphelweni; ubungakanani bomngxuma: umahluko olungileyo uya esiphelweni, umahluko ongalunganga uya esiphelweni.

(4) Isikhokelo seBurr.

(5) Zoba umbono onqamlezileyo kwicala lokukhupha, ukutsalwa koxinzelelo, ukukrazula, ukubhoboza iindawo ezixineneyo (iphakheji), njl.njl.

(6) Jonga izinto kunye nobukhulu bebhodi ukuze ubone ukuba ibhodi iyakwazi ukumelana nobukhulu bayo.

(7) Kwii-engile ezikhethekileyo, i-radius yangaphakathi ye-engile egobileyo (ngokubanzi i-R=0.5) kufuneka igobeke kwaye ivuleke.

(8) Iindawo ezinokuba neempazamo (ezifanayo nezingafaniyo) mazigqanyiswe.

(9) Imifanekiso emikhulu kufuneka yongezwe apho kukho ubungakanani obungaphezulu.

(10) Indawo eza kukhuselwa ngokutshiza kufuneka iboniswe.

Iinkqubo zokuvelisa

Ngokweyantlukwano kwisakhiwo seenxalenye zesinyithi, ukuhamba kwenkqubo kunokwahluka, kodwa isimbuku asidluli kula manqaku alandelayo.

- Ukusika: Kukho iindlela ezahlukeneyo zokusika, ikakhulu ezi zilandelayo.

①Umatshini wokucheba: Sisiqwenga esilula sezinto ezisebenzisa umatshini wokucheba ukusika imicu. Isetyenziswa kakhulu ekulungiseni isikhunta kunye nokulungisa. Ixabiso liphantsi, kwaye ukuchaneka kungaphantsi kwe-0.2, kodwa inokucubungula imicu okanye iibhloko kuphela ezingenamingxunya kwaye zingenamakona.

②Ukubethela: Isebenzisa ukubethela ukubethela iindawo ezithe tyaba emva kokutyhila iindawo ezikwipleyiti ngamanyathelo elinye okanye ngaphezulu ukwenza iimilo ezahlukeneyo zezinto. Iingenelo zayo kukuba zifutshane iiyure zomsebenzi, ukusebenza kakuhle, ukuchaneka okuphezulu, iindleko eziphantsi, kwaye ifanelekile kwimveliso enkulu. Kodwa kukuyila isikhunta.

③I-NC CNC blanking. Xa i-NC blanking, kufuneka uqale ubhale inkqubo yomatshini we-CNC. Sebenzisa isoftware yokucwangcisa ukubhala umfanekiso ozandisiweyo oza kutyhilwa ube yinkqubo enokuqatshelwa ngumatshini wokucubungula umzobo wedijithali we-NC, ukuze ukwazi ukubethelela nganye kwipleyiti inyathelo ngenyathelo ngokwezi nkqubo. Isakhiwo sisiqwenga esithe tyaba, kodwa isakhiwo saso sichaphazeleka bulwakhiwo lwesixhobo, ixabiso liphantsi, kwaye ukuchaneka yi-0.15.

④Ukusika nge-laser kukusetyenziswa kokusika nge-laser ukusika isakhiwo kunye nemilo yepleyiti ethe tyaba kwipleyiti enkulu ethe tyaba. Inkqubo ye-laser kufuneka icwangciswe ngendlela yokusika nge-NC. Ingalayisha iimilo ezahlukeneyo ezintsonkothileyo zeendawo ezithe tyaba ngexabiso eliphezulu kunye nokuchaneka okuphantsi. 0.1.

⑤Umatshini wokusarha: Sebenzisa ikakhulu iiprofayili ze-aluminium, iityhubhu zesikwere, iityhubhu zokuzoba, iibha ezingqukuva, njl.njl., ngexabiso eliphantsi kunye nokuchaneka okuphantsi.

2. Ukulungisa: ukucwila emanzini, ukucofa, ukuxovula, ukubhoboza.

I-angle ye-counterbore ngokubanzi yi-120℃, esetyenziselwa ukutsala ii-rivets, kwaye i-90℃ isetyenziselwa izikrufu ezifakwe kwi-countersunk kunye nokucofa imingxunya esezantsi ye-intshi.

3. Ukutsalwa kwemingxuma: Kukwabizwa ngokuba kukutsalwa kwemingxuma kunye nokujika imingxuma, oku kukudweba umngxuma omkhulu kancinci kumngxuma omncinci wesiseko, uze uwucofe. Ngokuyintloko ucutshungulwa ngesinyithi esincinci ukuze wonyuse amandla awo kunye nenani lemisonto. , Ukuze kuthintelwe amazinyo atyibilikayo, asetyenziswa ngokubanzi kubukhulu bepleyiti ebhityileyo, ukutsalwa kwemingxuma okuqhelekileyo okungaphantsi komhlaba, ubukhulu abutshintshi ngokusisiseko, kwaye ubukhulu buvunyelwe ukuba buncitshiswe ngama-30-40%, ngaphezulu kwama-40 kunokuphakama kwesiqhelo kokutsalwa. Kubude be-60%, ukuphakama okuphezulu kokutsalwa kunokufunyanwa xa ukuncitshiswa kungama-50%. Xa ubukhulu bepleyiti bukhulu, njenge-2.0, 2.5, njl.njl., bunokutsalwa ngqo.

4. Ukubethela: Yinkqubo yokucubungula esebenzisa ukwenza isikhunta. Ngokubanzi, ukubethela kuquka ukubethela, ukusika ikona, ukugquma, ukubethela isiqu esijijekileyo (ukugquma), ukubethela nokukrazula, ukubethela, ukwenza kunye nezinye iindlela zokucubungula. Ukucubungula kufuneka kube neendlela zokucubungula ezifanelekileyo. Isikhunta sisetyenziselwa ukugqiba imisebenzi, efana nokubethela nokubethela isikhunta, iisikhunta ezijijekileyo, ukukrazula iisikhunta, ukubethela isikhunta, ukwenza iisikhunta, njl. Lo msebenzi ugxila kakhulu kwindawo nakwicala.

5. Ukuqhoboshela ngoxinzelelo: Ngokuphathelele inkampani yethu, ukuqhoboshela ngoxinzelelo kubandakanya ikakhulu amantongomane okuqhoboshela ngoxinzelelo, izikrufu, njl. Lo msebenzi ugqitywa ngumatshini wokuqhoboshela ngoxinzelelo lwe-hydraulic okanye umatshini wokubhoboshela, oza kuziqhoboshela kwiindawo zesinyithi, kunye nomatshini wokuqhoboshela, ekufuneka unikele ingqalelo kwicala.

6. Ukugoba: Ukugoba kukugoba iindawo ezisicaba ze-2D zibe ziindawo ze-3D. Ukucubungula kufuneka kugqitywe ngebhedi yokugoba kunye neemolds ezihambelanayo zokugoba, kwaye kukwanolandelelwano oluthile lokugoba. Umgaqo kukuba ukusika okulandelayo akuphazamisi ukugoba kokuqala, kwaye ukuphazamiseka kuya kwenzeka emva kokugoba.

Inani leemicu ezigobileyo liphindwe ka-6 ubukhulu bepleyiti engaphantsi kwe-T=3.0mm ukuze kubalwe ububanzi begroove, ezinje ngezi: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Ukuhlelwa kwesikhunta sebhedi egobayo, imela ethe tye, isikere (80 ℃, 30 ℃).

Kukho iintanda xa ipleyiti yealuminiyam igobile. Ububanzi be-die slot esezantsi bunokwandiswa, kwaye i-die R ephezulu inokwandiswa (ukutsalwa kwe-annealing kungathintela iintanda).

Amanyathelo okuzikhusela xa ugoba: Ⅰ Ukuzoba, ubukhulu bepleyiti obufunekayo kunye nobungakanani; Ⅱ indlela yokugoba; Ⅲ i-engile yokugoba; Ⅳ ubungakanani bokugoba; Ⅵ imbonakalo, akukho miqolo ivumelekileyo kwizinto ezifakwe i-chrome. Ubudlelwane phakathi kokugoba kunye nenkqubo yokugoba i-pressure riveting ngokubanzi kukuqala kokugoba i-pressure riveting uze emva koko ugobe, kodwa ezinye izinto ziya kuphazamisana ne-pressure riveting, uze emva koko ucinezele kuqala, kwaye ezinye zifuna ukugoba-ukugoba-ukugoba-ukugoba kunye nezinye iinkqubo.

7. Ukuwelda: Inkcazo yokuwelda: Umgama phakathi kweeathom kunye neemolekyuli zezinto eziweldayo kunye nelatisi yeJingda zenza yonke into.

①Uhlobo: a Ukuwelda kwe-Fusion: ukuwelda kwe-argon arc, ukuwelda kwe-CO2, ukuwelda ngegesi, ukuwelda ngesandla. b Ukuwelda ngoxinzelelo: ukuwelda ngamabala, ukuwelda ngeempundu, ukuwelda ngamaqhuma. c Ukurhawuzelela: ukuwelda nge-chromium yombane, ucingo lwekopolo.

② Indlela yokuwelda: ukuwelda okukhuselwe yigesi ye-CO2. b Ukuwelda kwe-argon arc. c Ukuwelda okungabonakaliyo, njl. d Ukuwelda kwerobhothi.

Ukukhetha indlela yokuwelda kusekelwe kwiimfuno kunye nezixhobo zokwenyani. Ngokubanzi, ukuwelda okukhuselweyo ngegesi ye-CO2 kusetyenziswa ukuwelda ipleyiti yesinyithi; ukuwelda i-argon arc kusetyenziswa ukuwelda intsimbi engagqwaliyo kunye nepleyiti ye-aluminium. Ukuwelda kwerobhothi kunokonga iiyure zomsebenzi kwaye kuphucule ukusebenza kakuhle. Kwaye umgangatho wokuwelda, kunciphisa ubukhali bomsebenzi.

③ Uphawu lokuwelda: Ukuwelda kwe-Δ fillet, Д, ukuwelda kohlobo lwe-I, ukuwelda kohlobo lwe-V, ukuwelda kohlobo lwe-V olunecala elinye (V) Ukuwelda kohlobo lwe-V olunecala elingenanto (V), ukuwelda kwamabala (O), ukuwelda kweplagi okanye ukuwelda kwesloti (∏), ukuwelda kwe-Crimp (χ), ukuwelda okunecala elinye elinomfanekiso we-V onomphetho ongenanto (V), ukuwelda okunesimo se-U onomphetho ongenanto, ukuwelda okunesimo se-J onomphetho ongenanto, ukuwelda kwesiciko sangasemva, kunye nokuwelda ngakunye.

④ Iingcingo zotolo kunye nezihlanganisi.

⑤ Amanyathelo okukhusela kunye nokuwelda angekho.

Ukuwelda kwiindawo ezithile: ukuba amandla awonelanga, kungenziwa amaqhuma kwaye indawo yokuwelda ifakwe

Ukuwelda kwe-CO2: imveliso ephezulu, ukusetyenziswa kwamandla aphantsi, ixabiso eliphantsi, ukumelana nokugqwala okunamandla

Ukuwelda kwe-argon arc: ubunzulu bokunyibilika obungaphantsi, isantya sokuwelda esicothayo, ukusebenza kakuhle okuphantsi, iindleko eziphezulu zemveliso, iziphene zokufakwa kwe-tungsten, kodwa kunenzuzo yomgangatho olungileyo wokuwelda, kwaye kunokuwelda iintsimbi ezingezizo i-ferrous, ezifana ne-aluminium, i-copper, i-magnesium, njl.

⑥ Izizathu zokuguqulwa kwe-welding: ukulungiswa okunganelanga ngaphambi kokuwelda, kufuneka ezinye izixhobo. Inkqubo yokuphucula ii-jigs zokuwelda ezingalunganga. Ulandelelwano lwe-welding alulunganga.

⑦ Indlela yokulungisa ukuguquka kwesakhiwo seWelding: Indlela yokulungisa ilangatye. Indlela yokungcangcazela. Indlela yokubethela. Indlela yokuguga eyenziweyo.

ezinye ii-apps

Amanyathelo okucubungula iindawo zokucubungula kwindawo yokusebenzela yesinyithi ngala: uvavanyo lwangaphambi kokuveliswa kwemveliso, ukuveliswa kovavanyo lokucubungula imveliso kunye nokuveliswa kweqela lemveliso. Kwinyathelo lokuvelisa uvavanyo lokucubungula imveliso, kufuneka inxibelelane nabathengi ngexesha, kwaye emva kokufumana uvavanyo lokucubungula olufanelekileyo, imveliso inokuveliswa ngobuninzi.

Iteknoloji yokubhola nge-laser yeyona teknoloji isebenzayo yokuqala kwiteknoloji yokucubungula izinto ze-laser. Ukubhola nge-laser kwindawo yokusebenzela yesinyithi kusetyenziswa ii-laser ezishukumayo, ezinamandla aphezulu kunye nexesha elifutshane. Ingacubungula imingxunya emincinci ye-1μm. Ifanelekile ngokukodwa ekucubunguleni imingxunya emincinci ene-engile ethile kunye nezinto ezincinci, kwaye ikwafanelekile ekucubunguleni amandla kunye nobunzima. Imingxunya emincinci enzulu kunye nemingxunya emincinci kwiindawo zezixhobo eziphakamileyo okanye ezibuthathaka nezithambileyo.

I-laser inokuphumeza ukugrumba kweendawo ezitshisayo ze-turbine yegesi, kwaye isiphumo sokugrumba sinokufezekisa icala elinemilinganiselo emithathu, kwaye inani linokufikelela kumawaka. Izinto ezigqobhoziweyo ziquka intsimbi engatyiwayo, ii-alloys ze-nickel-chromium-iron, kunye nee-alloys ezisekelwe kwi-HASTELLOY. Itekhnoloji yokugrumba nge-laser ayichaphazeleki ziimpawu zoomatshini zezinto, kwaye kulula ukuzenza ngokuzenzekelayo.

Ngophuhliso lwetekhnoloji yokubhola nge-laser, umatshini wokusika nge-laser uye wasebenza ngokuzenzekelayo. Ukusetyenziswa kwishishini lesinyithi kutshintshe indlela yokucubungula itekhnoloji yesinyithi yendabuko, kwasebenza ngaphandle komntu, kwaphucula kakhulu ukusebenza kakuhle kwemveliso, kwaza kwasebenza yonke inkqubo. Ukusebenza ngokuzenzekelayo kukhuthaze uphuhliso loqoqosho lwesinyithi, kwaza kwaphucula isiphumo sokubhoboza ukuya kwinqanaba eliphezulu, kwaye isiphumo sokucubungula siyamangalisa.

Ixesha lokuthumela: Meyi-27-2021