Kukonza zitsulo zapepala

Kukonza zitsulo ndi ukadaulo wa hub womwe akatswiri a zitsulo ayenera kumvetsetsa, ndipo ndi njira yofunika kwambiri popanga zinthu zachitsulo. Kukonza zitsulo kumaphatikizapo njira zachikhalidwe zodula, kuchotsa zinthu zobisika, kupinda ndi kupanga ndi magawo a njira, komanso njira zosiyanasiyana zopangira ndi kukonza zinthu zozizira, mfundo zosiyanasiyana zogwirira ntchito ndi njira zogwirira ntchito, komanso ukadaulo watsopano wopaka zitsulo ndi ukadaulo watsopano. Kukonza zitsulo zachitsulo kumatchedwa kukonza zitsulo zachitsulo.

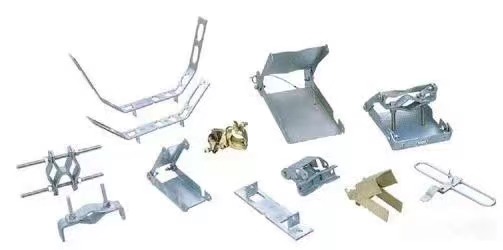

Kukonza zitsulo za pepala kumatchedwa kukonza zitsulo za pepala. Mwachitsanzo, kugwiritsa ntchito mbale popanga ma chimney, migolo yachitsulo, matanki amafuta, matanki amafuta, mapaipi opumira mpweya, zigongono, zigongono, masikweya, ma funnel, ndi zina zotero. Njira zazikulu zimaphatikizapo kudula, kupindika, kupindika, kupanga, kuwotcherera, riveting, ndi zina zotero. Chidziwitso china cha geometry. Zigawo zachitsulo za pepala ndi zigawo zoonda zachitsulo za pepala, ndiko kuti, zigawo zomwe zitha kukonzedwa poponda, kupindika, kutambasula ndi njira zina. Tanthauzo lalikulu ndi gawo lomwe lili ndi makulidwe osasintha panthawi yokonza. Lofanana ndi zoponyera, zopangira, zida zopangira, ndi zina zotero.

Kusankha zinthu

Zipangizo zomwe zimagwiritsidwa ntchito kwambiri pokonza zitsulo ndi mbale yopukutidwa yozizira (SPCC), mbale yopukutidwa yotentha (SHCC), mbale yopangidwa ndi galvanized (SECC, SGCC), mkuwa (CU), mkuwa wofiira, mkuwa wa beryllium, mbale ya aluminiyamu (6061, 5052) 1010, 1060, 6063, duralumin, ndi zina zotero), ma profiles a aluminiyamu, chitsulo chosapanga dzimbiri (pamwamba pagalasi, pamwamba pa brushed, pamwamba pa matte), kutengera ntchito ya chinthucho, kusankha zipangizo ndikosiyana, ndipo nthawi zambiri kumafunika kuganiziridwa poganizira momwe chinthucho chigwiritsidwira ntchito komanso mtengo wake.

(1) Cold rolled sheet SPCC, yomwe imagwiritsidwa ntchito makamaka popangira ma varnish ndi kuphika, yotsika mtengo, yosavuta kupanga, komanso makulidwe a zinthu ≤ 3.2mm.

(2) SHCC yophimbidwa ndi moto, yopangidwa ndi T≥3.0mm, imagwiritsanso ntchito ma electroplating, utoto, wotsika mtengo, koma wovuta kupanga, makamaka zigawo zathyathyathya.

(3) SECC, pepala la galvanized la SGCC. Bolodi la electrolytic la SECC limagawidwa m'magulu awiri: N ndi P. N imagwiritsidwa ntchito makamaka pochiza pamwamba komanso pamtengo wokwera. P imagwiritsidwa ntchito popopera zinthu.

(4) Mkuwa, womwe umagwiritsidwa ntchito kwambiri ndi zinthu zoyendetsera magetsi, pamwamba pake pamakhala nickel plating, chrome plating, kapena palibe chithandizo, mtengo wake ndi wokwera.

(5) Mbale ya aluminiyamu, nthawi zambiri imagwiritsa ntchito chromate pamwamba (J11-A), okosijeni (okosijeni woyendetsa, okosijeni wa mankhwala), mtengo wokwera, siliva wopangira, nickel plating.

(6) Ma profile a aluminiyamu, zipangizo zokhala ndi mapangidwe ovuta zimagwiritsidwa ntchito kwambiri m'mabokosi ang'onoang'ono osiyanasiyana. Kukonza pamwamba pake ndi kofanana ndi mbale ya aluminiyamu.

(7) Chitsulo chosapanga dzimbiri, chimagwiritsidwa ntchito kwambiri popanda kukonzedwa pamwamba, ndipo mtengo wake ndi wokwera.

Zipangizo zomwe zimagwiritsidwa ntchito kwambiri

- Chitsulo chopangidwa ndi chitsulo cha SECC

Gawo la SECC ndi coil yachitsulo yozungulira yozizira, yomwe imakhala chinthu chopangidwa ndi magetsi pambuyo pochotsa mafuta, kusakaniza, kuyika ma electroplating ndi njira zosiyanasiyana zochizira pambuyo pa kuyeretsa pa mzere wopangira magetsi wozungulira. SECC sikuti ili ndi mphamvu zamakina zokha komanso kuthekera kofanana ndi pepala lachitsulo lozungulira lozizira, komanso imakhala ndi kukana dzimbiri komanso mawonekedwe okongola. Ndi yopikisana kwambiri ndipo imatha kusinthidwa pamsika wazinthu zamagetsi, zida zapakhomo ndi mipando. Mwachitsanzo, SECC imagwiritsidwa ntchito kwambiri m'makompyuta.

2. Wamba ozizira adakulungidwa pepala SPCC

SPCC imatanthauza kuzunguliza kosalekeza kwa ma ingot achitsulo kudzera m'mafakitale ozizira ozungulira kupita ku ma coil achitsulo kapena mapepala okhala ndi makulidwe ofunikira. Palibe chitetezo pamwamba pa SPCC, ndipo chimasungunuka mosavuta chikawonekera mumlengalenga, makamaka pamalo ozizira, liwiro la okosijeni limakulitsidwa, ndipo dzimbiri lofiira lakuda limawonekera. Pamwamba pake payenera kupakidwa utoto, kupakidwa ndi electroplated kapena chitetezo china chikagwiritsidwa ntchito. SPCC imatanthauza kuzunguliza kosalekeza kwa ma ingot achitsulo kudzera m'mafakitale ozizira ozungulira kupita ku ma coil achitsulo kapena mapepala okhala ndi makulidwe ofunikira. Palibe chitetezo pamwamba pa SPCC, ndipo chimasungunuka mosavuta chikawonekera mumlengalenga, makamaka pamalo ozizira, liwiro la okosijeni limakulitsidwa, ndipo dzimbiri lofiira lakuda limawonekera. Pamwamba pake payenera kupakidwa utoto, kupakidwa ndi electroplated kapena chitetezo china chikagwiritsidwa ntchito.

3. Chitsulo chotentha cha SGCC

Chophimba chachitsulo chotenthedwa ndi madzi otentha chimatanthauza chinthu chomalizidwa theka pambuyo pochipukuta ndi kuviika kapena kuzizira, chomwe chimatsukidwa ndikumizidwa mosalekeza mu bafa yosungunuka ya zinc pa kutentha kwa pafupifupi 460°C, kotero kuti pepala lachitsulolo limakutidwa ndi zinc wosanjikiza kenako ndikuzimitsidwa ndikufewetsa zinthu za SGCC zimakhala zolimba kuposa zinthu za SECC, zimakhala ndi ductility yofooka (pewani kapangidwe kozama kojambula), zinc wosanjikiza wokhuthala, komanso kusasinthasintha bwino.

4. Chitsulo chosapanga dzimbiri SUS304

Chimodzi mwa zitsulo zosapanga dzimbiri zomwe zimagwiritsidwa ntchito kwambiri. Popeza chili ndi Ni (nickel), chimakhala ndi kukana dzimbiri komanso kutentha kuposa chitsulo cha Cr (chromium). Chili ndi mphamvu zabwino kwambiri zamakanika, sichimalimbitsa kutentha, komanso sichimasinthasintha.

5. Chitsulo chosapanga dzimbiri SUS301

Kuchuluka kwa Cr (chromium) ndi kochepa kuposa kwa SUS304, ndipo kukana dzimbiri ndi kochepa. Komabe, imatha kukhala ndi mphamvu yabwino yogwira ntchito komanso kulimba poyimitsa pambuyo poyimitsa, ndipo imakhala ndi kusinthasintha kwabwino. Imagwiritsidwa ntchito kwambiri pa ma shrapnel springs ndi anti-EMI.

Ndemanga yojambula

Kuti tipeze njira yoyendetsera gawo, choyamba tiyenera kudziwa zofunikira zosiyanasiyana zaukadaulo pa kujambula gawo; kuwunikanso zojambula ndiye njira yofunika kwambiri yopangira njira yoyendetsera gawo.

(1) Onani ngati zojambulazo zatha.

(2) Ubale pakati pa chithunzicho ndi mawonekedwe ake, kaya chizindikirocho chili chomveka bwino, chokwanira, komanso gawo la kukula kwake.

(3) Ubale pakati pa mapangano, miyeso yofunika kwambiri ya zofunikira pa mapangano.

(4) Kusiyana pakati pa mitundu yakale ndi yatsopano ya zithunzi.

(5) Kumasulira zithunzi m'zilankhulo zakunja.

(6) Kusintha kwa ma code a tebulo.

(7) Kuyankha ndi kuthetsa mavuto ojambula.

(8) Zinthu zofunika.

(9) Zofunikira pa khalidwe ndi zofunikira pa njira.

(10) Kutulutsidwa kovomerezeka kwa zojambulazo kuyenera kusindikizidwa ndi chisindikizo chowongolera khalidwe.

Kusamalitsa

Mawonekedwe okulirapo ndi mawonekedwe a pulani (2D) kutengera chithunzi cha gawo (3D).

(1) Njira yowonjezera iyenera kukhala yoyenera, ndipo iyenera kukhala yosavuta kusunga zinthu ndi kukonzedwa mosavuta.

(2) Sankhani bwino njira ya mpata ndi m'mphepete, T=2.0, mpata ndi 0.2, T=2-3, mpata ndi 0.5, ndipo njira ya m'mphepete imagwiritsa ntchito mbali zazitali ndi mbali zazifupi (mapanelo a zitseko).

(3) Kuganizira moyenera za miyeso ya kulekerera: kusiyana koipa kumapita kumapeto, kusiyana kwabwino kumapita theka; kukula kwa dzenje: kusiyana kwabwino kumapita kumapeto, kusiyana koipa kumapita theka.

(4) Kuwongolera kwa Burr.

(5) Jambulani mawonekedwe ozungulira mbali yochokera komwe kumachokera, kukakamiza, kung'amba, kubowola mfundo zozungulira (phukusi), ndi zina zotero.

(6) Chongani zinthu ndi makulidwe a bolodi kuti muwone ngati bolodiyo ndi lokwanira makulidwe ake.

(7) Pa ma ngodya apadera, utali wamkati wa ngodya yopindika (nthawi zambiri R=0.5) uyenera kupindika ndikutsegulidwa.

(8) Malo omwe nthawi zambiri amalakwitsa (osafanana) ayenera kuonetsedwa.

(9) Zithunzi zokulira ziyenera kuwonjezedwa pamene pali kukula kwakukulu.

(10) Malo oti atetezedwe ndi kupopera ayenera kusonyezedwa.

Njira zopangira

Malinga ndi kusiyana kwa kapangidwe ka zigawo zachitsulo, kayendedwe ka njira kangakhale kosiyana, koma chiwerengero chonse sichidutsa mfundo zotsatirazi.

- Kudula: Pali njira zosiyanasiyana zodulira, makamaka njira zotsatirazi.

①Makina odulira ubweya: Ndi chinthu chosavuta chomwe chimagwiritsa ntchito makina odulira ubweya kudula mizere. Amagwiritsidwa ntchito makamaka pokonza ndi kukonza nkhungu. Mtengo wake ndi wotsika, ndipo kulondola kwake ndi kochepera 0.2, koma amatha kungokonza mizere kapena mabuloko opanda mabowo ndi ngodya.

②Kuboola: Imagwiritsa ntchito kuboola kuti itulutse zigawo zathyathyathya pambuyo potsegula zigawo zomwe zili pa mbaleyo mu sitepe imodzi kapena zingapo kuti ipange mawonekedwe osiyanasiyana a zipangizo. Ubwino wake ndi waufupi, kugwira ntchito bwino, kulondola kwambiri, mtengo wotsika, ndipo ndi yoyenera kupanga zinthu zambiri. Koma kupanga nkhungu.

③Kuchotsa zinthu mu CNC. Mukachotsa zinthu mu CNC, choyamba muyenera kulemba pulogalamu yopangira makina a CNC. Gwiritsani ntchito pulogalamu yopangira mapulogalamu kuti mulembe chithunzi chojambulidwa chomwe chatsegulidwa mu pulogalamu yomwe ingathe kuzindikirika ndi makina opangira zojambula za digito a NC, kuti athe kuyika chilichonse pa mbale pang'onopang'ono malinga ndi mapulogalamu awa. Kapangidwe kake ndi kosalala, koma kapangidwe kake kamakhudzidwa ndi kapangidwe ka chida, mtengo wake ndi wotsika, ndipo kulondola kwake ndi 0.15.

④Kudula pogwiritsa ntchito laser ndi kugwiritsa ntchito laser kudula kapangidwe ndi mawonekedwe a mbale yathyathyathya pa mbale yayikulu yathyathyathya. Pulogalamu ya laser iyenera kukonzedwa ngati kudula kwa NC. Imatha kuyika mawonekedwe osiyanasiyana ovuta a zigawo zathyathyathya ndi mtengo wokwera komanso kulondola kochepa. 0.1.

⑤Makina odulira: Gwiritsani ntchito makamaka ma profiles a aluminiyamu, machubu ozungulira, machubu ojambulira, mipiringidzo yozungulira, ndi zina zotero, zotsika mtengo komanso zolondola pang'ono.

2. Woyenerera: kuponda, kugogoda, kupukuta, kuboola.

Ngodya ya counterbore nthawi zambiri imakhala 120℃, imagwiritsidwa ntchito kukoka ma rivets, ndipo 90℃ imagwiritsidwa ntchito pokoka zomangira zozungulira ndi kugogoda mabowo apansi a inchi.

3. Kupindika: Kumatchedwanso kujambula mabowo ndi kutembenuza mabowo, komwe ndiko kujambula dzenje lalikulu pang'ono pa dzenje laling'ono loyambira, kenako nkuligwira. Kawirikawiri limakonzedwa ndi chitsulo chopyapyala kuti liwonjezere mphamvu zake ndi kuchuluka kwa ulusi. , Pofuna kupewa kutsetsereka kwa mano, nthawi zambiri amagwiritsidwa ntchito pa makulidwe a mbale yopyapyala, kupindika kosaya bwino mozungulira dzenje, makulidwewo sasintha kwenikweni, ndipo makulidwewo amaloledwa kuchepetsedwa ndi 30-40%, 40-kuposa kutalika kwabwinobwino kwa kupindika komwe kungapezeke. Pa kutalika kwa 60%, kutalika kwakukulu kwa kupindika kungapezeke pamene kupendekeka kuli 50%. Pamene makulidwe a mbaleyo ndi akulu, monga 2.0, 2.5, ndi zina zotero, amatha kuponyedwa mwachindunji.

4. Kuboola: Ndi njira yopangira zinthu yomwe imagwiritsa ntchito kupanga nkhungu. Kawirikawiri, kuboola kumaphatikizapo kuboola, kudula ngodya, kubisa zinthu, kuboola thupi lozungulira (bump), kuboola ndi kung'amba, kuboola, kupanga ndi njira zina zogwirira ntchito. Kukonza kumafunika kukhala ndi njira zogwirira ntchito zofanana. Nkhungu imagwiritsidwa ntchito kumaliza ntchito, monga kuboola ndi kubisa zinthu, nkhungu zozungulira, kuboola nkhungu, kuboola nkhungu, kupanga nkhungu, ndi zina zotero. Ntchitoyi imayang'ana kwambiri malo ndi komwe ikupita.

5. Kupopera mphamvu: Ponena za kampani yathu, kupopera mphamvu kumaphatikizapo mtedza wopopera mphamvu, zomangira, ndi zina zotero. Ntchitoyi imamalizidwa ndi makina opopera mphamvu a hydraulic kapena makina opopera mphamvu, kuwapopera ku zigawo zachitsulo, ndi njira yopopera mphamvu, ndipo ayenera kusamala ndi komwe akupita.

6. Kupindika: Kupindika ndiko kupindika zigawo za 2D zosalala kukhala zigawo za 3D. Kukonza kuyenera kumalizidwa ndi bedi lopindika ndi mawonekedwe opindika ofanana, ndipo kulinso ndi njira inayake yopindika. Mfundo yake ndi yakuti kudula kotsatira sikusokoneza kupindika koyamba, ndipo kusokonezeka kudzachitika mutapinda.

Chiwerengero cha mizere yopindika ndi kuwirikiza kasanu ndi kamodzi kuposa makulidwe a mbale pansi pa T=3.0mm kuti muwerengere m'lifupi mwa groove, monga: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Kugawa nkhungu ya bedi, mpeni wowongoka, scimitar (80 ℃, 30 ℃).

Pali ming'alu pamene mbale ya aluminiyamu yapindika. M'lifupi mwa malo otsika a die slot mutha kuonjezedwa, ndipo die R yapamwamba ikhoza kuonjezedwa (kunyowa kungapewe ming'alu).

Chenjezo mukapinda: Ⅰ Kujambula, makulidwe ndi kuchuluka kwa mbale komwe kumafunika; Ⅱ njira yopinda; Ⅲ ngodya yopinda; Ⅳ kukula kopinda; Ⅵ mawonekedwe, palibe mikwingwirima yomwe imaloledwa pa zinthu zopangidwa ndi chrome. Ubale pakati pa kupindika ndi njira yopopera mphamvu nthawi zambiri umakhala woyamba kupindika mphamvu kenako kupindika, koma zipangizo zina zimasokoneza kupindika kwa mphamvu, kenako kukanikiza kaye, ndipo zina zimafuna kupindika-kupopera mphamvu-kenako kupindika ndi njira zina.

7. Kuwotcherera: Tanthauzo la kuwotcherera: Mtunda pakati pa maatomu ndi mamolekyu a zinthu zowotcherera ndi latisi ya Jingda umapanga zonse.

①Kugawa: a Kuwotcherera kwa Fusion: kuwotcherera kwa argon arc, kuwotcherera kwa CO2, kuwotcherera kwa gasi, kuwotcherera kwamanja. b Kuwotcherera kwa Pressure: kuwotcherera malo, kuwotcherera matako, kuwotcherera kwa bump. c Brazing: kuwotcherera kwa chromium yamagetsi, waya wamkuwa.

② Njira yowotcherera: kuwotcherera kotetezedwa ndi mpweya wa CO2. b Kuwotcherera kwa Argon arc. c Kuwotcherera kwa malo, ndi zina zotero. d Kuwotcherera kwa Robot.

Kusankha njira yowotcherera kumadalira zofunikira zenizeni ndi zipangizo. Kawirikawiri, kuwotcherera kwa CO2 komwe kumatetezedwa ndi mpweya kumagwiritsidwa ntchito powotcherera mbale zachitsulo; kuwotcherera kwa argon arc kumagwiritsidwa ntchito powotcherera zitsulo zosapanga dzimbiri ndi mbale za aluminiyamu. Kuwotcherera kwa robot kumatha kusunga maola ogwira ntchito ndikuwonjezera magwiridwe antchito. Ndipo ubwino wa kuwotcherera umachepetsa mphamvu ya ntchito.

③ Chizindikiro cha kutchinjiriza: Δ fillet welding, Д, I type welding, V type welding, single side V type welding (V) V type welding yokhala ndi blunt edge (V), spot welding (O), plug welding kapena slot welding (∏), Crimp welding (χ), single-side V-shaped welding yokhala ndi blunt edge (V), U-shaped welding yokhala ndi blunt, J-shaped welding yokhala ndi blunt, back cover welding, ndi welding iliyonse.

④ Mawaya ndi zolumikizira za mivi.

⑤ Palibe njira zowotcherera ndi zodzitetezera.

Kuwotcherera malo: ngati mphamvu sikokwanira, ma bumps angapangidwe ndipo malo owotcherera amayikidwa

Kuwotcherera kwa CO2: kupanga bwino kwambiri, kugwiritsa ntchito mphamvu zochepa, mtengo wotsika, kukana dzimbiri mwamphamvu

Kuwotcherera kwa Argon arc: kuya kwa kusungunuka kosaya kwambiri, liwiro lowotcherera pang'onopang'ono, magwiridwe antchito otsika, mtengo wokwera wopanga, zolakwika zophatikizika ndi tungsten, koma kuli ndi ubwino wokhala ndi mtundu wabwino wowotcherera, ndipo kumatha kuwotcherera zitsulo zopanda chitsulo, monga aluminiyamu, mkuwa, magnesium, ndi zina zotero.

⑥ Zifukwa zosinthira kuluka kwa welding: kukonzekera kosakwanira musanaluke, pakufunika zida zina zowonjezera. Kukonza njira yogwiritsira ntchito ma jig osagwira bwino ntchito. Njira yolukitsira welding si yabwino.

⑦ Njira Yokonzera Kusintha kwa Kuwotcherera: Njira Yokonzera Moto. Njira Yogwedera. Njira Yopangira Kudula. Njira Yokonzera Kukalamba.

mapulogalamu ena

Njira zogwiritsira ntchito zida zogwirira ntchito mu workshop ya chitsulo ndi izi: kuyesa zinthu zisanachitike, kuyesa kupanga zinthu ndi kupanga zinthu zambiri. Mu gawo loyesera kupanga zinthu, ziyenera kulankhulana ndi makasitomala nthawi yake, ndipo pambuyo poyesa kukonza koyenera, chinthucho chikhoza kupangidwa mochuluka.

Ukadaulo woboola pogwiritsa ntchito laser ndiye ukadaulo wakale kwambiri wothandiza paukadaulo wokonza zinthu pogwiritsa ntchito laser. Kuboola pogwiritsa ntchito laser mu workshop yachitsulo nthawi zambiri kumagwiritsa ntchito ma laser opangidwa ndi pulsed, omwe ali ndi mphamvu zambiri komanso nthawi yochepa. Amatha kukonza mabowo ang'onoang'ono a 1μm. Ndi oyenera kwambiri kukonza mabowo ang'onoang'ono okhala ndi ngodya inayake komanso zinthu zopyapyala, komanso ndi oyeneranso kukonza mphamvu ndi kuuma. Mabowo ang'onoang'ono akuya komanso mabowo ang'onoang'ono m'zigawo zina za zinthu zazitali kapena zofooka komanso zofewa.

Laser imatha kukumba zigawo zoyatsira za turbine ya gasi, ndipo zotsatira zake zokumba zimatha kukumba mbali zitatu, ndipo chiwerengerocho chikhoza kufika zikwizikwi. Zipangizo zobowoka zimaphatikizapo chitsulo chosapanga dzimbiri, nickel-chromium-iron alloys, ndi HASTELLOY-based alloys. Ukadaulo wokumba laser sukhudzidwa ndi mphamvu za makina a chinthucho, ndipo n'zosavuta kuchita zokha.

Ndi chitukuko cha ukadaulo woboola pogwiritsa ntchito laser, makina odulira pogwiritsa ntchito laser agwira ntchito yokha. Kugwiritsa ntchito kwa makina opangira zitsulo kwasintha njira yogwiritsira ntchito ukadaulo wachikhalidwe wa zitsulo zopangira zitsulo, kwagwira ntchito popanda munthu, kwathandiza kwambiri kupanga bwino, komanso kwathandiza njira yonse. Kugwira ntchito yokha kwathandizira chitukuko cha chuma cha zitsulo zopangira zitsulo zopangira zitsulo, ndipo kwathandiza kuti ntchito yoboola ikhale yapamwamba kwambiri, ndipo zotsatira zake ndi zodabwitsa.

Nthawi yotumizira: Meyi-27-2021