Ka hana ʻana i ka pepa metala

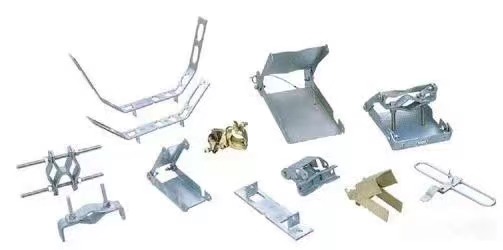

ʻO ka hana ʻana i ka pepa metala kahi ʻenehana kikowaena e pono ai nā loea pepa metala e hoʻomaopopo, a he hana koʻikoʻi nō hoʻi ia i ka hana ʻana i nā huahana pepa metala. Hoʻokomo pū ka hana ʻana i ka pepa metala i nā ʻano hana ʻoki kuʻuna, ka hoʻopaʻa ʻana, ke kūlou ʻana a me ke kūkulu ʻana a me nā palena hana, a me nā ʻano hana make stamping anu like ʻole a me nā palena hana, nā loina hana like ʻole a me nā ʻano hana, a me nā ʻenehana stamping hou a me nā ʻenehana hou. Ua kapa ʻia ka hana ʻana i ka pepa metala ʻāpana he hana pepa metala.

ʻO ka hana ʻana i ka pepa metala ua kapa ʻia ʻo ka hana ʻana i ka pepa metala. ʻO ke ʻano kikoʻī, no ka laʻana, ka hoʻohana ʻana i nā papa e hana i nā lua ahi, nā pahu hao, nā pahu wahie, nā pahu ʻaila, nā paipu hoʻoulu ea, nā kuʻekuʻe lima, nā kuʻekuʻe lima, nā huinahā, nā funnels, a pēlā aku. ʻO nā kaʻina hana nui e pili ana i ka ʻoki ʻana, ke kūlou ʻana, ke kūlou ʻana, ka hoʻokumu ʻana, ka hoʻopaʻa ʻana, ka riveting, a pēlā aku. Kekahi ʻike geometric. ʻO nā ʻāpana pepa metala he mau ʻāpana pepa metala lahilahi, ʻo ia hoʻi, nā ʻāpana hiki ke hana ʻia ma ke kahakaha ʻana, ke kūlou ʻana, ke kīkoʻo ʻana a me nā ʻano ʻē aʻe. ʻO ka wehewehe laulā he ʻāpana me ka mānoanoa mau i ka wā e hana ai. E pili ana i ka hoʻolei ʻana, ka forgings, nā ʻāpana mīkini, a pēlā aku.

Koho mea

ʻO nā mea i hoʻohana nui ʻia i ka hana ʻana i ka metala pepa he papa ʻōwili anu (SPCC), papa ʻōwili wela (SHCC), papa galvanized (SECC, SGCC), keleawe (CU) keleawe, keleawe ʻulaʻula, keleawe beryllium, papa alumini (6061, 5052) 1010, 1060, 6063, duralumin, etc.), nā ʻaoʻao alumini, kila kila (ʻili aniani, ʻili palaki, ʻili matte), ma muli o ke ʻano o ka huahana, ʻokoʻa ke koho ʻana o nā mea, a pono e noʻonoʻo ʻia mai ka hoʻohana ʻana a me ke kumukūʻai o ka huahana.

(1) ʻO ka pepa SPCC i ʻōwili anu ʻia, i hoʻohana nui ʻia no ka electroplating a me ka hoʻomoʻa ʻana i nā ʻāpana varnish, haʻahaʻa ke kumukūʻai, maʻalahi ke ʻano, a me ka mānoanoa o ka mea ≤ 3.2mm.

(2) ʻO ka pepa SHCC i ʻōwili wela ʻia, mea T≥3.0mm, hoʻohana pū i ka electroplating, nā ʻāpana pena, haʻahaʻa ke kumukūʻai, akā paʻakikī ke hana, ʻo nā ʻāpana pālahalaha nui.

(3) SECC, pepa galvanized SGCC. Ua māhele ʻia ka papa electrolytic SECC i ka mea N a me ka mea P. Hoʻohana nui ʻia ka mea N no ka mālama ʻana i ka ʻili a me ke kumukūʻai kiʻekiʻe. Hoʻohana ʻia ka mea P no nā ʻāpana i pīpī ʻia.

(4) Keleawe, hoʻohana nui ʻia nā mea alakaʻi, ʻo ka mālama ʻili he nikala, chrome, a i ʻole ʻaʻohe mālama, he kumukūʻai kiʻekiʻe.

(5) Papa aluminika, hoʻohana nui ʻia ka chromate ʻili (J11-A), oxidation (conductive oxidation, chemical oxidation), ke kumu kūʻai kiʻekiʻe, kālā, nickel plating.

(6) ʻO nā ʻaoʻao alumini, nā mea me nā ʻano ʻāpana paʻakikī e hoʻohana nui ʻia i nā pahu liʻiliʻi like ʻole. ʻO ke ʻano o ka mālama ʻana i ka ʻili e like me ka papa alumini.

(7) Ke kila kila, hoʻohana nui ʻia me ka ʻole o ka mālama ʻana i ka ʻili, a kiʻekiʻe ke kumukūʻai.

Nā mea i hoʻohana pinepine ʻia

- Pepa kila galvanized SECC

ʻO ke kumu o SECC he wili kila ʻōwili anu maʻamau, kahi e lilo ai i huahana electro-galvanized ma hope o ka degreasing, pickling, electroplating a me nā kaʻina hana like ʻole ma ka laina hana electro-galvanizing hoʻomau. ʻAʻole wale nā waiwai mechanical a me ke kaʻina hana like o ka pepa kila ʻōwili anu maʻamau, akā he kūpaʻa kiʻekiʻe hoʻi i ka corrosion a me ke ʻano hoʻonaninani. He hoʻokūkū kiʻekiʻe a hiki ke pani ʻia ma ka mākeke o nā huahana uila, nā lako home a me nā lako. No ka laʻana, hoʻohana pinepine ʻia ʻo SECC i nā hihia kamepiula.

2. ʻO ka pepa SPCC i ʻōwili anu maʻamau

ʻO SPCC ke ʻōwili mau nei o nā ʻiʻo kila ma o nā wili anu i loko o nā ʻōwili kila a i ʻole nā palapala o ka mānoanoa i koi ʻia. ʻAʻohe pale ma luna o ka ʻili o SPCC, a maʻalahi ke oxidized i ka wā e hōʻike ʻia ai i ka lewa, ʻoi aku hoʻi i kahi kaiapuni humid, hoʻolalelale ʻia ka wikiwiki o ka oxidation, a ʻike ʻia ka ʻulaʻula ʻeleʻele. Pono e pena ʻia ka ʻili, electroplated a i ʻole kekahi pale ʻē aʻe i ka wā e hoʻohana ʻia ai. ʻO SPCC ke ʻōwili mau nei o nā ʻiʻo kila ma o nā wili anu i loko o nā ʻōwili kila a i ʻole nā palapala o ka mānoanoa i koi ʻia. ʻAʻohe pale ma luna o ka ʻili o SPCC, a maʻalahi ke oxidized i ka wā e hōʻike ʻia ai i ka lewa, ʻoi aku hoʻi i kahi kaiapuni humid, hoʻolalelale ʻia ka wikiwiki o ka oxidation, a ʻike ʻia ka ʻulaʻula ʻeleʻele. Pono e pena ʻia ka ʻili, electroplated a i ʻole kekahi pale ʻē aʻe i ka wā e hoʻohana ʻia ai.

3.Hot-dip galvanized steel sheet SGCC

ʻO ke kila kila galvanized wela e pili ana i ka huahana semi-hoʻopau ma hope o ka ʻōwili wela a me ka pickling a i ʻole ka ʻōwili anu, kahi i holoi ʻia a hoʻomau ʻia i loko o ka ʻauʻau zinc hoʻoheheʻe ʻia ma kahi mahana o 460 ° C, i uhi ʻia ka pepa kila me kahi papa zinc a laila hoʻopau ʻia a hoʻomaʻamaʻa ʻia ka mea SGCC ʻoi aku ka paʻakikī ma mua o ka mea SECC, he ductility maikaʻi ʻole (e pale i ka hoʻolālā kaha kiʻi hohonu), ka papa zinc mānoanoa, a me ka weldability maikaʻi ʻole.

4. kila kila SUS304

ʻO kekahi o nā kila kila i hoʻohana nui ʻia. No ka mea aia ka Ni (nickel), ʻoi aku ka maikaʻi o kona kūpaʻa ʻana i ka pala a me ke kūpaʻa wela ma mua o ke kila Cr (chromium). He maikaʻi loa kona mau waiwai mechanical, ʻaʻohe hanana paʻakikī o ka mālama wela, a ʻaʻohe elasticity.

5. kila kila SUS301

ʻOi aku ka haʻahaʻa o ka nui o Cr (chromium) ma mua o SUS304, a ʻaʻole maikaʻi ke kūpaʻa ʻana i ka pala. Eia nō naʻe, hiki iā ia ke loaʻa ka ikaika tensile maikaʻi a me ka paʻakikī i ka wā e kuʻi ai ma hope o ka hana anu, a he elasticity maikaʻi. Hoʻohana nui ʻia no nā pūnāwai shrapnel a me ka anti-EMI.

Loiloi kaha kiʻi

No ka hōʻuluʻulu ʻana i ke kaʻina hana o kahi ʻāpana, pono mua mākou e ʻike i nā koi loea like ʻole o ke kaha kiʻi ʻāpana; ʻo ka loiloi kaha kiʻi ka loulou koʻikoʻi loa i ka hōʻuluʻulu ʻana o ke kaʻina hana ʻāpana.

(1) E nānā inā ua pau nā kiʻi.

(2) ʻO ka pilina ma waena o ke kaha kiʻi a me ka nānā ʻana, inā maopopo ka lepili, piha, a me ke ana o ka nui.

(3) Nā pilina ʻaha kanaka, nā ana koʻikoʻi o nā koi ʻaha kanaka.

(4) ʻO ka ʻokoʻa ma waena o nā mana kahiko a me nā mana hou o nā kiʻi.

(5) Unuhi ʻana i nā kiʻi ma nā ʻōlelo ʻē.

(6) Hoʻololi ʻana o nā code papa.

(7) Manaʻo hoʻihoʻi a me ka hoʻopau ʻana i nā pilikia kaha kiʻi.

(8) Mea Hana.

(9) Nā koi maikaʻi a me nā koi kaʻina hana.

(10) Pono e hoʻopaʻa ʻia ka hoʻokuʻu kūhelu ʻana o nā kiʻi me kahi sila hoʻomalu maikaʻi.

Nā Mālama

ʻO ka hiʻohiʻona i hoʻonui ʻia he hiʻohiʻona hoʻolālā (2D) i hoʻokumu ʻia ma ke kaha kiʻi ʻāpana (3D).

(1) Pono ke ʻano hoʻonui e kūpono, a pono e maʻalahi hoʻi e mālama i nā mea a me ka hiki ke hana.

(2) E koho pono i ke ʻano hakahaka a me ka lihi, T=2.0, ʻo ka hakahaka he 0.2, T=2-3, ʻo ka hakahaka he 0.5, a hoʻohana ke ʻano lihi i nā ʻaoʻao lōʻihi a me nā ʻaoʻao pōkole (nā panela puka).

(3) Noʻonoʻo kūpono i nā ana hoʻomanawanui: hele ka ʻokoʻa maikaʻi ʻole a hiki i ka hopena, hele ka ʻokoʻa maikaʻi i ka hapalua; nui o ka lua: hele ka ʻokoʻa maikaʻi a hiki i ka hopena, hele ka ʻokoʻa maikaʻi ʻole i ka hapalua.

(4) Ke kuhikuhi ʻana o Burr.

(5) E kaha kiʻi i kahi hiʻohiʻona ʻokiʻoki ma ke kuhikuhi o ka unuhi ʻana, ke kaomi ʻana i ka riveting, ka haehae ʻana, ka punching ʻana i nā kiko convex (pūʻolo), a pēlā aku.

(6) E nānā i ka mea a me ka mānoanoa o ka papa i ka hoʻomanawanui mānoanoa o ka papa.

(7) No nā kihi kūikawā, pono e kulou a wehe ʻia ke radius o loko o ke kihi kūlou (ma ke ʻano maʻamau ʻo R = 0.5).

(8) Pono e hōʻike ʻia nā wahi i maʻalahi i ka hewa (like asymmetry).

(9) Pono e hoʻohui ʻia nā kiʻi i hoʻonui ʻia ma kahi i ʻoi aku ka nui.

(10) Pono e hōʻike ʻia kahi e pale ʻia e ka pīpī ʻana.

Nā kaʻina hana hana

Wahi a ka ʻokoʻa o ke ʻano o nā ʻāpana metala pepa, hiki ke ʻokoʻa ke kahe o ke kaʻina hana, akā ʻaʻole iʻoi aku ka huina ma mua o nā helu aʻe.

- ʻOki ʻana: Aia nā ʻano ʻoki like ʻole, ʻo ia nā ʻano hana ma lalo nei.

①Mīkini ʻokiʻoki: He ʻāpana mea maʻalahi ia e hoʻohana ana i ka mīkini ʻokiʻoki e ʻoki i nā ʻāpana. Hoʻohana nui ʻia ia no ka hoʻopau ʻana i ka ʻōpala a me ka hoʻomākaukau ʻana i ke kūkulu ʻana. He haʻahaʻa ke kumukūʻai, a ʻoi aku ka pololei ma mua o 0.2, akā hiki iā ia ke hana i nā ʻāpana a i ʻole nā poloka me nā lua ʻole a me nā kihi ʻole. .

②Punch: Hoʻohana ia i ka punch e punch i nā ʻāpana pālahalaha ma hope o ka wehe ʻana i nā ʻāpana ma ka pā i hoʻokahi a ʻoi aku paha mau ʻanuʻu e hana i nā ʻano mea like ʻole. ʻO kona mau pono he mau hola kanaka pōkole, ka pono kiʻekiʻe, ke kiko kiʻekiʻe, ke kumukūʻai haʻahaʻa, a kūpono ia no ka hana nui ʻana. , Akā no ka hoʻolālā ʻana i ka ʻōmole.

③NC CNC blanking. I ka wā e NC blanking ai, pono ʻoe e kākau mua i kahi polokalamu mīkini CNC. E hoʻohana i ka polokalamu papahana e kākau i ke kiʻi i kaha ʻia i loko o kahi polokalamu hiki ke ʻike ʻia e ka mīkini hana kaha kiʻi kikohoʻe NC, i hiki iā ia ke kuʻi i kēlā me kēia ma ka pā i kēlā me kēia ʻanuʻu e like me kēia mau polokalamu. He ʻāpana pālahalaha ke ʻano, akā ua hoʻopilikia ʻia kona ʻano e ke ʻano o ka mea hana, haʻahaʻa ke kumukūʻai, a ʻo ka pololei he 0.15.

④ʻO ka ʻoki laser ka hoʻohana ʻana i ka ʻoki laser e ʻoki i ke ʻano a me ke ʻano o ka papa pālahalaha ma kahi papa pālahalaha nui. Pono e hoʻolālā ʻia ka papahana laser e like me ka ʻoki NC. Hiki iā ia ke hoʻouka i nā ʻano paʻakikī like ʻole o nā ʻāpana pālahalaha me ke kumukūʻai kiʻekiʻe a me ka pololei haʻahaʻa. 0.1.

⑤Mīkini ʻokiʻoki: Hoʻohana nui i nā ʻaoʻao alumini, nā paipu huinaha, nā paipu kaha kiʻi, nā kaola poepoe, a me nā mea ʻē aʻe, me ke kumu kūʻai haʻahaʻa a me ka pololei haʻahaʻa.

2.Mea hoʻoponopono: hoʻopio ʻana i ka lepo, kāʻei ʻana, hoʻomaʻemaʻe hou ʻana, ʻeli ʻana.

ʻO ke kihi counterbore maʻamau he 120 ℃, hoʻohana ʻia no ka huki ʻana i nā rivets, a ʻo 90 ℃ hoʻohana ʻia no nā wili countersunk a me ke kī ʻana i nā lua lalo ʻīniha.

3. Flanging: Ua kapa ʻia hoʻi ʻo ia he hole-drawing a me ka hoʻohuli ʻana i ka lua, ʻo ia hoʻi ke kahakiʻi ʻana i kahi lua nui iki ma kahi lua kumu liʻiliʻi, a laila e paʻi iā ia. Hana nui ʻia me ka metala pepa lahilahi e hoʻonui i kona ikaika a me ka helu o nā kaula. , I mea e pale aku ai i nā niho paheʻe, hoʻohana pinepine ʻia no ka mānoanoa o ka papa lahilahi, ʻo ka flanging pāpaʻu maʻamau a puni ka lua, ʻaʻole i loli ka mānoanoa, a ʻae ʻia ka mānoanoa e hoʻomāmā ʻia e 30-40%, 40-ʻoi aku ke kiʻekiʻe ma mua o ke kiʻekiʻe flanging maʻamau. No ke kiʻekiʻe o 60%, hiki ke loaʻa ke kiʻekiʻe flanging kiʻekiʻe loa ke 50% ka lahilahi. Ke nui aʻe ka mānoanoa o ka papa, e like me 2.0, 2.5, a pēlā aku, hiki ke paʻi pololei ʻia.

4. Kuʻi: He hana hana ia e hoʻohana ana i ka hana ʻana i ka mold. Ma keʻano laulā, ʻo ka hana ʻana i ka punching e komo pū ana me ka punching, ka ʻoki kihi, ka blanking, ka punching convex hull (bump), ka punching a me ka haehae ʻana, ka punching, ka hoʻokumu ʻana a me nā ʻano hana ʻē aʻe. Pono ka hana ʻana i nā ʻano hana like. Hoʻohana ʻia ka mold e hoʻopau i nā hana, e like me ka punching a me ka blanking molds, convex molds, haehae molds, punching molds, forming molds, etc. Hoʻolohe nui ka hana i ke kūlana a me ke kuhikuhi ʻana.

5. Kaomi ʻana i ke kaomi: No kā mākou hui, ʻo ke kaomi ʻana i ke kaomi e pili ana i nā nati kaomi, nā wili, a pēlā aku. Hoʻopau ʻia ka hana e ka mīkini kaomi hydraulic a i ʻole ka mīkini punching, e hoʻopili ana iā lākou i nā ʻāpana metala pepa, a me ke ala riveting, pono e hoʻolohe i ke kuhikuhi ʻana.

6. Kulou: ʻO ke kulou ʻana, ʻo ia ke pelu ʻana i nā ʻāpana pālahalaha 2D i nā ʻāpana 3D. Pono e hoʻopau ʻia ka hana ʻana me kahi moena pelu a me nā ʻōmole pelu e pili ana, a he ʻano pelu nō hoʻi. ʻO ke kumumanaʻo, ʻaʻole e hoʻopilikia ka ʻoki aʻe i ka pelu mua, a e hana ʻia ke keakea ma hope o ka pelu ʻana.

ʻO ka helu o nā ʻāpana kūlou he 6 manawa ka mānoanoa o ka papa ma lalo o T=3.0mm e helu ai i ka laulā o ke awāwa, e like me: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Ka hoʻokaʻawale ʻana o ka moena kūlou, ka pahi pololei, ka scimitar (80 ℃, 30 ℃).

Aia nā māwae ke kūlou ʻia ka papa alumini. Hiki ke hoʻonui ʻia ka laulā o ke kaha make haʻahaʻa, a hiki ke hoʻonui ʻia ka make luna R (hiki i ka annealing ke pale aku i nā māwae).

Nā akahele i ke kūlou ʻana: Ⅰ Ke kaha kiʻi ʻana, ka mānoanoa a me ka nui o ka pā i koi ʻia; Ⅱ ke kuhikuhi kūlou; Ⅲ ke kihi kūlou; Ⅳ ka nui kūlou; Ⅵ ke ʻano, ʻaʻohe ʻae ʻia nā creases ma ka mea chromed electroplated. ʻO ka pilina ma waena o ke kūlou ʻana a me ke kaʻina hana riveting kaomi maʻamau ka riveting kaomi mua a laila kūlou, akā e hoʻopilikia kekahi mau mea i ka riveting kaomi, a laila kaomi mua, a koi kekahi i ke kūlou-kaomi riveting-a laila kūlou a me nā kaʻina hana ʻē aʻe.

7. Kuʻihao: Wehewehena kuʻihao: ʻO ka mamao ma waena o nā ʻātoma a me nā molekala o ka mea i kuʻihao ʻia a me ka lattice Jingda e hana i kahi holoʻokoʻa.

①Hoʻokaʻawale ʻana: a Kuʻihao Fusion: kuʻihao argon arc, kuʻihao CO2, kuʻihao kinoea, kuʻihao lima. b Kuʻihao kaomi: kuʻihao kiko, kuʻihao butt, kuʻihao puʻupuʻu. c Hoʻopaʻa lima: kuʻihao chromium uila, uea keleawe.

② Ke ʻano hana kuʻihao: a Kuʻihao pale kinoea CO2. b Kuʻihao ʻākuhi Argon. c Kuʻihao kiko, a pēlā aku. d Kuʻihao lopako.

ʻO ke koho ʻana o ke ʻano hana kuʻihao e pili ana i nā koi maoli a me nā mea hana. Ma ke ʻano laulā, hoʻohana ʻia ka kuʻihao pale kinoea CO2 no ka kuʻihao pā hao; hoʻohana ʻia ka kuʻihao argon arc no ka kuʻihao kila kila a me ka pā alumini. Hiki i ka kuʻihao robot ke mālama i nā hola hana a hoʻomaikaʻi i ka pono o ka hana. A me ka maikaʻi o ka kuʻihao, e hōʻemi i ka ikaika o ka hana.

③ Hōʻailona kuʻihao: kuʻihao ʻāpana Δ, Д, kuʻihao ʻano I, kuʻihao ʻano V, kuʻihao ʻano V hoʻokahi ʻaoʻao (V) kuʻihao ʻano V me kahi lihi blunt (V), kuʻihao kiko (O), kuʻihao plug a i ʻole kuʻihao slot (∏), kuʻihao Crimp (χ), kuʻihao ʻano V hoʻokahi ʻaoʻao me kahi lihi blunt (V), kuʻihao ʻano U me ka blunt, kuʻihao ʻano J me ka blunt, kuʻihao uhi hope, a me kēlā me kēia kuʻihao.

④ Nā uea pua a me nā mea hoʻohui.

⑤ Nā hana kuʻihao a me nā hana pale i nalowale.

Kuʻi kiko: inā ʻaʻole lawa ka ikaika, hiki ke hana ʻia nā puʻupuʻu a kau ʻia ka wahi kuʻi

Kuʻihao CO2: huahua kiʻekiʻe, hoʻohana ikehu haʻahaʻa, kumukūʻai haʻahaʻa, kūpaʻa ikaika i ka popo

ʻO ka hoʻoheheʻe ʻana o Argon arc: hohonu hoʻoheheʻe pāpaʻu, wikiwiki o ka hoʻoheheʻe ʻana, haʻahaʻa ka pono, kiʻekiʻe ke kumukūʻai hana, nā hemahema hoʻokomo tungsten, akā he pono ke ʻano maikaʻi o ka hoʻoheheʻe ʻana, a hiki ke hoʻoheheʻe i nā metala non-ferrous, e like me ka alumini, keleawe, magnesium, a pēlā aku.

⑥ Nā kumu no ka hoʻololi ʻana o ka wili ʻana: ʻaʻole lawa ka hoʻomākaukau ʻana ma mua o ka wili ʻana, pono nā mea paʻa hou. Hoʻomaikaʻi i ke kaʻina hana no nā jigs wili maikaʻi ʻole. ʻAʻole maikaʻi ke kaʻina wili.

⑦ Ke ʻAno Hoʻoponopono Hoʻololi ʻAno Kuʻi: Ke ʻAno Hoʻoponopono Lapa. Ke ʻAno Haʻalulu. Ke ʻAno Kuʻi. Ke ʻAno ʻElemakule Hana.

nā polokalamu ʻē aʻe

ʻO nā kaʻina hana o nā ʻāpana hana i loko o ka hale hana pepa metala: ka hoʻāʻo mua ʻana o ka huahana, ka hana hoʻāʻo hana huahana a me ka hana ʻana i ka hui huahana. I ke kaʻina hana hoʻāʻo hana huahana, pono e kamaʻilio me nā mea kūʻai aku i ka manawa, a ma hope o ka loaʻa ʻana o ka loiloi o ka hana like, hiki ke hana nui ʻia ka huahana.

ʻO ka ʻenehana wili laser ka ʻenehana laser mua loa i ka ʻenehana hana mea laser. ʻO ka wili laser ma ka hale hana metala pepa e hoʻohana pinepine i nā lasers pulsed, nona ka nui o ka ikehu a me ka manawa pōkole. Hiki iā ia ke hana i nā lua liʻiliʻi o 1μm. He kūpono loa ia no ka hana ʻana i nā lua liʻiliʻi me kahi kihi a me ka mea lahilahi, a kūpono hoʻi no ka hana ʻana i ka ikaika a me ka paʻakikī. ʻO nā lua liʻiliʻi hohonu a me nā lua liʻiliʻi ma nā ʻāpana o nā mea kiʻekiʻe a ʻoi aku ka palupalu a palupalu.

Hiki i ka laser ke hoʻokō i ka wili ʻana o nā ʻāpana kuni o ka turbine kinoea, a hiki i ka hopena wili ke hoʻokō i ke kuhikuhi ʻekolu-dimensional, a hiki i ka helu ke hiki i nā tausani. ʻO nā mea i perforated ʻia e komo pū me ke kila kila, nā nickel-chromium-iron alloys, a me nā HASTELLOY-based alloys. ʻAʻole i hoʻopilikia ʻia ka ʻenehana wili laser e nā waiwai mechanical o ka mea, a ʻoi aku ka maʻalahi o ka hoʻokō ʻana i ka automation.

Me ka hoʻomohala ʻana o ka ʻenehana ʻeli laser, ua hoʻokō ka mīkini ʻoki laser i ka hana automated. Ua hoʻololi ka noi ʻana i ka ʻoihana pepa metala i ke ʻano hana o ka ʻenehana pepa metala kuʻuna, ua hoʻokō i ka hana unmanned, hoʻomaikaʻi nui i ka pono hana, a ua hoʻokō i ke kaʻina holoʻokoʻa. Ua hoʻolaha ka hana automated i ka hoʻomohala ʻana o ka hoʻokele waiwai pepa metala, a ua hoʻomaikaʻi i ka hopena punching i kahi pae kiʻekiʻe, a he mea kupaianaha ka hopena hana.

Ka manawa hoʻouna: Mei-27-2021