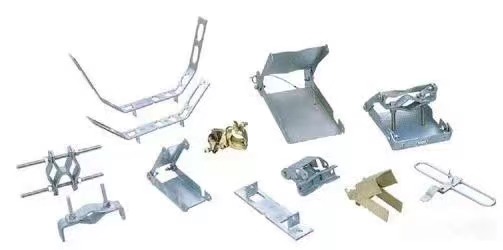

Gutunganya ibyuma by'amabati

Gutunganya ibyuma ni ikoranabuhanga ry’inyuma abatekinisiye b’ibyuma bakeneye gusobanukirwa, kandi ni inzira y’ingenzi mu gukora ibikoresho by’ibyuma. Gutunganya ibyuma birimo uburyo gakondo bwo gukata, gusiba, kunama no gukora hamwe n’ibipimo by’imikorere, hamwe n’imiterere itandukanye y’icyuma gikonjesha n’ibipimo by’imikorere, amahame atandukanye y’imikorere n’uburyo bw’imikorere, hamwe n’ikoranabuhanga rishya ryo gukata n’ikoranabuhanga rishya. Gutunganya ibyuma by’ibyuma byitwa gutunganya ibyuma by’icyuma.

Gutunganya ibyuma byitwa gutunganya ibyuma by'amabati. Urugero, ikoreshwa ry'amasahani mu gukora imashini zitanga umwotsi, imiyoboro y'icyuma, ibigega bya lisansi, ibigega bya peteroli, imiyoboro y'umwuka, inkokora, inkokora, kare, imiyoboro, nibindi. Inzira nyamukuru zirimo gukata, kunama, kunama, gushushanya, gusudira, gukurura, nibindi. Ubumenyi bumwe na bumwe bwa geometrike. Ibice by'icyuma by'amabati ni ibice by'icyuma bito, ni ukuvuga ibice bishobora gutunganywa hakoreshejwe gukata, kunama, kunagura n'ubundi buryo. Igisobanuro rusange ni igice gifite ubugari buhoraho mu gihe cyo gutunganya. Bijyanye n'imashini zikoreshwa mu gukata, gucura, ibice by'imashini, nibindi.

Guhitamo ibikoresho

Ibikoresho bikoreshwa muri rusange mu gutunganya ibyuma ni icyuma gikonje gikozwe mu buryo bwa "cold rolled plate" (SPCC), icyuma gishyushye gikozwe mu buryo bwa "hot rolled plate" (SHCC), icyuma gikozwe mu buryo bwa "galvanized plate" (SECC, SGCC), umuringa (CU), umuringa utukura, umuringa wa beryllium, icyuma cya aluminiyumu (6061, 5052) 1010, 1060, 6063, duralumin, nibindi), imiterere ya aluminiyumu, icyuma kitagira umugese (ubuso bw'indorerwamo, ubuso bukozwe mu buryo bwa "brushed", ubuso bukozwe mu buryo bwa "matte"), bitewe n'uruhare rw'umusaruro, amahitamo y'ibikoresho aratandukanye, kandi muri rusange bigomba kuzirikanwa ku ikoreshwa ry'umusaruro n'ikiguzi cyawo.

(1) SPCC ikonje irambitse, ikoreshwa cyane cyane mu gusiga no guteka ibice bya varnish, ihendutse, yoroshye kuyishushanya, kandi ifite ubugari bwa ≤ 3.2mm.

(2) SHCC y'urupapuro rushyushye, ibikoresho T≥3.0mm, ikoresha kandi electroplating, irangi, ihendutse, ariko bigoye kuyikora, ahanini ibice birambuye.

(3) SECC, urupapuro rwa galvanized rwa SGCC. Urubaho rwa electrolytic rwa SECC rugabanyijemo ibikoresho bya N n'ibikoresho bya P. Ibikoresho bya N ahanini bikoreshwa mu gutunganya ubuso kandi bihenze. Ibikoresho bya P bikoreshwa mu bice byasizwe.

(4) Umuringa, ahanini ukoreshwa mu bikoresho biyobora amashanyarazi, isukura hejuru ni ugushyiraho nikeli, gushushanya chrome, cyangwa nta gukosora, igiciro ni kinini.

(5) Isahani ya aluminiyumu, muri rusange ikoresha chromate yo hejuru (J11-A), ogisijeni (ogisijeni itwara amazi, ogisijeni y'ibinyabutabire), ihendutse, irangi rya feza, irangi rya nikeli.

(6) Ibikoresho bya aluminiyumu, bifite imiterere ikomeye ikoreshwa mu dusanduku duto dutandukanye bikoreshwa cyane. Uburyo bwo gutunganya ubuso ni bumwe n'uburyo aluminiyumu ikoreshwamo.

(7) Icyuma kidakoresha ifu, gikoreshwa cyane cyane nta gusukura ubuso, kandi igiciro cyacyo ni kinini.

Ibikoresho bikunze gukoreshwa

- Ibati ry'icyuma rya galvanised SECC

Igice cya SECC ni icyuma gisanzwe gikonjeshwa n'ubukonje, kiba ibikoresho bya electro-galvanized nyuma yo gukuraho amavuta, gusya, gusiga electroplating n'ibindi bikorwa bitandukanye nyuma yo kugitunganya ku murongo uhoraho w'icyuma gikonjeshwa n'ubukonje. SECC ntabwo ifite gusa imiterere ya mekanike n'uburyo bwo kuyitunganya nk'icyuma gikonjeshwa n'ubukonje, ahubwo inafite ubushobozi bwo kurwanya ingese no gusa neza. Irapiganwa cyane kandi ishobora gusimburwa ku isoko ry'ibikoresho by'ikoranabuhanga, ibikoresho byo mu rugo n'ibikoresho byo mu nzu. Urugero, SECC ikoreshwa cyane mu bikoresho bya mudasobwa.

2. SPCC isanzwe ikonje irazingirwa

SPCC yerekeza ku kuzunguruka kw'ibyuma bikozwe mu byuma bikonje biva mu byuma bikonje bijya mu byuma bikonje cyangwa impapuro z'ubugari bukenewe. Nta burinzi buri ku buso bwa SPCC, kandi byoroshye gukaraba iyo bishyizwe mu kirere, cyane cyane mu kirere gikonje, umuvuduko wa oxidation wihuta, kandi ingese y'umutuku wijimye igaragara. Ubuso bugomba gusigwa irangi, gusigwa n'amashanyarazi cyangwa ubundi burinzi iyo bukoreshwa. SPCC yerekeza ku kuzunguruka kw'ibyuma bikozwe mu byuma bikonje biva mu byuma bikonje bijya mu byuma bikonje cyangwa impapuro z'ubugari bukenewe. Nta burinzi buri ku buso bwa SPCC, kandi byoroshye gukaraba iyo bishyizwe mu kirere, cyane cyane mu kirere gikonje, umuvuduko wa oxidation wihuta, kandi ingese y'umutuku wijimye igaragara. Ubuso bugomba gusigwa irangi, gusigwa n'amashanyarazi cyangwa ubundi burinzi iyo bukoreshwa.

3. Icupa ry'icyuma gishyushye cya SGCC

Igikoresho cy'icyuma gishyushye cyitwa "hot-dip galvanized coil" kivuga ku gicuruzwa cyarangije gushyuha no gukaraba cyangwa gukonjesha, kikagezwa kandi kigahora cyinjizwa mu bwogero bwa zinc bushongeshejwe ku bushyuhe bwa dogere selisiyusi 460, ku buryo urupapuro rw'icyuma rutwikiriwe n'urwego rwa zinc hanyuma rugashiraho kandi ibikoresho bya SGCC bikonje kurusha ibikoresho bya SECC, bifite ubushobozi buke bwo gukurura (wirinde imiterere y'igishushanyo cyimbitse), urwego rwa zinc rurerure, kandi ntirushobora gusudira neza.

4. Icyuma kidakoresha ifuru SUS304

Imwe mu byuma bitagira umugese ikoreshwa cyane. Kubera ko irimo Ni (nikeli), ifite ubushobozi bwo kurwanya ingese no kurwanya ubushyuhe kurusha Cr (chromium). Ifite ubushobozi bwiza cyane bwo gukora, nta bushyuhe butuma idakomera, kandi nta bukonje.

5. Icyuma kidakoresha ifuru SUS301

Ingano ya Cr (chromium) iri hasi ugereranyije n’iya SUS304, kandi ubushobozi bwo kurwanya ingese buragabanuka. Ariko, ishobora kugira imbaraga zo gukurura no gukomera mu gukanda nyuma yo gukora mu bukonje, kandi ifite ubushobozi bwo guhindagurika neza. Ikoreshwa cyane cyane mu gukata ibyuma n’ibice birwanya EMI.

Isuzuma ry'ibishushanyo

Kugira ngo dukusanye inzira y'igice, tugomba kubanza kumenya ibisabwa mu bya tekiniki mu gushushanya igice; isuzuma ry'igishushanyo ni ryo sano ry'ingenzi mu gukusanya inzira y'igice.

(1) Reba niba ibishushanyo byuzuye.

(2) Isano iri hagati y'igishushanyo n'ishusho, niba icyapa gisobanutse neza, cyuzuye, n'ingano yacyo.

(3) Imibanire y'iteraniro, ibipimo by'ingenzi by'ibisabwa mu guteraniriza hamwe.

(4) Itandukaniro riri hagati y'ibishushanyo mbonera bya kera n'ibishya.

(5) Guhindura amashusho mu ndimi z'amahanga.

(6) Guhindura kode z'imbonerahamwe.

(7) Gusubiza no gukemura ibibazo byo gushushanya.

(8) Ibikoresho.

(9) Ibisabwa ku buziranenge n'ibisabwa mu buryo bwo gutunganya ibintu.

(10) Itangazo ryemewe ry’ibishushanyo rigomba gushyirwaho ikimenyetso cy’ubuziranenge.

Amabwiriza yo Kwirinda

Ishusho yagutse ni ishusho y'igishushanyo (2D) ishingiye ku gishushanyo cy'ibice (3D).

(1) Uburyo bwo kwagura bugomba kuba bukwiriye, kandi bugomba kuba bworoshye mu kuzigama ibikoresho no kubitunganya neza.

(2) Hitamo neza uburyo bwo gutandukanya icyuho n'impande, T=2.0, icyuho ni 0.2, T=2-3, icyuho ni 0.5, kandi uburyo bwo gutandukanya impande bukoresha impande ndende n'impande ngufi (inzugi).

(3) Gusuzuma neza ibipimo by'ubworoherane: itandukaniro riri hagati y'ibipimo bibiri n'ibice bibiri, itandukaniro riri hagati y'ibipimo bibiri n'ibice bibiri; ingano y'umwobo: itandukaniro riri hagati y'ibipimo bibiri n'ibice bibiri, itandukaniro riri hagati y'ibipimo bibiri n'ibice bibiri.

(4) Icyerekezo cya Burr.

(5) Shushanya ishusho y'igice cy'ingenzi mu cyerekezo cyo gukuramo, gukurura umuvuduko, gushwanyagurika, gukubita ingingo zipfundikiye (paki), n'ibindi.

(6) Genzura ibikoresho n'ubugari bw'ikibaho ukurikije ubushobozi bw'ikibaho.

(7) Ku mfuruka zidasanzwe, uruziga rw'imbere rw'inguni ihengamye (muri rusange R=0.5) rugomba guhindurwa no gupfunduka.

(8) Ahantu hakunze kubaho amakosa (asymmetry isa) hagomba kugaragazwa.

(9) Amashusho manini agomba kongerwaho aho ingano zirenze.

(10) Ahantu hagomba kurindwa hakoreshejwe imashini ziterwa hagomba kugaragazwa.

Ingamba zo gukora

Dukurikije itandukaniro riri mu miterere y'ibice by'icyuma, inzira y'ibikorwa ishobora gutandukana, ariko igiteranyo ntikirenza ingingo zikurikira.

- Gukata: Hari uburyo butandukanye bwo gukata, cyane cyane uburyo bukurikira.

①Imashini yo kogosha: Ni igice cyoroheje cy'ibikoresho gikoresha imashini yo kogosha mu gukata imirongo. Ikoreshwa cyane cyane mu gusiga ifu no gutegura ibumba. Igiciro ni gito, kandi ubuziranenge buri munsi ya 0.2, ariko ishobora gusa gutunganya imirongo cyangwa bloki nta mwobo cyangwa mfuruka.

②Gukubita: Ikoresha uburyo bwo gukubita kugira ngo ikuremo ibice birambuye nyuma yo gukuramo ibice biri ku isahani mu ntambwe imwe cyangwa nyinshi kugira ngo ikore imiterere itandukanye y'ibikoresho. Ibyiza byayo ni amasaha magufi y'abakozi, imikorere myiza cyane, ubushishozi bwinshi, igiciro gito, kandi ikwiriye gukorwa ku bwinshi. Ariko gushushanya ibumba.

③NC CNC ifunze. Iyo ufunze NC, ugomba kubanza kwandika porogaramu yo gukora imashini ya CNC. Koresha porogaramu ya porogaramu kugira ngo wandike ishusho ifunze muri porogaramu ishobora kumenyekana n'imashini itunganya igishushanyo ya NC digitale, kugira ngo ibashe gukubita buri kimwe ku isahani intambwe ku yindi hakurikijwe izi porogaramu. Imiterere ni igice kirambuye, ariko imiterere yacyo igirwaho ingaruka n'imiterere y'igikoresho, igiciro ni gito, kandi ubuziranenge ni 0.15.

④Gukata hakoreshejwe laser ni ugukoresha laser mu gukata imiterere n'imiterere y'icyuma giteretse ku gipande kinini giteretse. Porogaramu ya laser igomba gutegurwa nk'icyuma giteretse ku gipande cya NC. Ishobora gushyiramo imiterere itandukanye y'ibice biteretse ku giciro cyo hejuru kandi ikora neza. 0.1.

⑤Imashini yo gukata: Koresha cyane cyane imiterere ya aluminiyumu, imiyoboro kare, imiyoboro yo gushushanya, imigozi izengurutse, nibindi, bihendutse kandi bifite ubuziranenge buke.

2. Umukozi: gucukura amazi mu buryo bunyuranye, gukomanga, gucukura amazi mu buryo bunyuranye, gucukura amazi mu buryo bunyuranye.

Inguni yo kugabanya ubushyuhe muri rusange ni 120℃, ikoreshwa mu gukurura rivets, naho 90℃ ikoreshwa mu gukurura vis no gukanda umwobo wo hasi wa santimetero.

3. Gupfunyika: Nanone byitwa gukurura imyobo no guhindukiza imyobo, ari byo gukurura umwobo munini gato ku mwobo muto wo hasi, hanyuma ukawukanda. Utunganywa cyane cyane n'icyuma cyoroshye kugira ngo wongere imbaraga zawo n'umubare w'imigozi. , Kugira ngo wirinde kunyerera kw'amenyo, muri rusange bikoreshwa ku bugari bw'isahani nto, gupfunyika ku buryo busanzwe hafi y'umwobo, ubugari ntibuhinduka, kandi ubugari bwemerewe kugabanywaho 30-40%, burenga 40% ugereranyije n'uburebure busanzwe bwo gupfunyika bushobora kuboneka. Ku burebure bwa 60%, uburebure ntarengwa bwo gupfunyika bushobora kuboneka iyo gupfunyika ari 50%. Iyo ubugari bw'isahani ari bunini, nka 2.0, 2.5, nibindi, bushobora gupfunyikaho ako kanya.

4. Gukubita: Ni uburyo bwo gutunganya bukoresha ibumba. Muri rusange, gutunganya ibumba birimo gukubita, gukata impande, gusiba, gukuba igice cy’inyuma (bump), gukuba no gushwanyagurika, gukuba, gushushanya n'ubundi buryo bwo gutunganya. Uburyo bwo gutunganya bugomba kugira uburyo bujyanye n'ubwo. Ibumba rikoreshwa mu kurangiza imirimo, nko gukuba no gusiba ibumba, ibumba rinini, gukuba, gukuba ibumba, gukora ibumba, nibindi. Igikorwa cyibanda cyane cyane ku mwanya n'icyerekezo.

5. Gutera umuvuduko: Ku bijyanye n'ikigo cyacu, gutera umuvuduko ahanini bikubiyemo utubuto two gutera umuvuduko, vis, n'ibindi. Igikorwa kirangizwa n'imashini itera umuvuduko wa hydraulic cyangwa imashini itera umuvuduko, ikawutera ku bice by'icyuma, na Way itera umuvuduko, igomba kwita ku cyerekezo.

6. Gupfunyika: Gupfunyika ni ugupfunyika ibice bya 2D birambuye mo ibice bya 3D. Gutunganya bigomba kurangizwa n'igitanda gipfunyika n'ibishushanyo bihuye, kandi bifite urukurikirane runaka rwo gupfunyika. Ihame ni uko gupfunyika gukurikiraho bitabangamira gupfunyika kwa mbere, kandi ingaruka zizavuka nyuma yo gupfunyika.

Umubare w'imirongo igonda ni ukubye inshuro 6 ubunini bw'isahani iri munsi ya T=3.0mm kugira ngo harebwe ubugari bw'umuyoboro, nka: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Ishyirwa mu byiciro ry'ibimera byo mu buriri, icyuma kigororotse, icyuma cyo gukaraba (80 ℃, 30 ℃).

Hari imiturire iyo icyuma cya aluminiyumu gipfundikiye. Ubugari bw'umwanya wo hasi w'icyuma bushobora kongerwa, naho icyuma cyo hejuru R gishobora kongerwa (gufunga bishobora kwirinda imiturire).

Amabwiriza yo kwirinda mu gihe ugonda: Ⅰ Gushushanya, ubugari n'ingano by'isahani bikenewe; Ⅱ icyerekezo cyo gugonda; Ⅲ inguni yo gugonda; Ⅳ Ingano yo gugonda; Ⅵ Ishusho, nta mikurire yemewe ku bikoresho bya chrome byakozwe na electroplated. Isano iri hagati yo gugonda no gukomanga umuvuduko muri rusange ni ugukomanga umuvuduko wa mbere hanyuma ugakomanga, ariko bimwe mu bikoresho bizabangamira gukomanga umuvuduko, hanyuma bigakanda mbere, kandi bimwe bisaba gukomanga umuvuduko-hanyuma ugakomanga n'ibindi bikorwa.

7. Gusudira: Ibisobanuro byo gusudira: Intera iri hagati ya atome na molekile z'ibikoresho byasudiwe n'urukuta rwa Jingda ikora byose.

①Ishyirwa mu byiciro: a Gusudira mu buryo bwa Fusion: Gusudira mu buryo bwa Argon arc, Gusudira mu buryo bwa CO2, Gusudira mu buryo bwa Gazi, Gusudira mu buryo bwa Manual. b Gusudira mu buryo bwa Pressure: Gusudira ahantu hatandukanye, Gusudira mu buryo bwa Butt, Gusudira mu buryo bwa Bump. c Gusudira mu buryo bwa Brazing: Gusudira mu buryo bwa chromium y'amashanyarazi, Insinga z'umuringa.

② Uburyo bwo gusudira: gusudira hakoreshejwe gaze ya CO2. b Gusudira Argon arc. c Gusudira ahantu runaka, nibindi. d Gusudira Robot.

Uburyo bwo gusudira bushingiye ku bisabwa n'ibikoresho nyabyo. Muri rusange, gusudira hakoreshejwe gaze ya CO2 ikoreshwa mu gusudira icyuma; gusudira argon arc ikoreshwa mu gusudira icyuma kitagira umugese na aluminiyumu. Gusudira robo bishobora kuzigama amasaha y'akazi no kunoza imikorere. Kandi ubuziranenge bwo gusudira bugabanya imbaraga z'akazi.

③ Ikimenyetso cyo gusudira: Δ fillet suiling, Д, I type welding, V type welding, single side V type welding (V) V type welding with a blunt edge (V), spot welding (O), plug welding or slot welding (∏), Crimp welding (χ), single-side V-shaped welding with a blunt edge (V), U-shaped welding with blunt, J-shaped welding with blunt, back cover welding, na buri welding.

④ Insinga n'ibihuza.

⑤ Habuze ingamba zo gusudira no gukumira.

Gusudira ahantu hadahagije: iyo imbaraga zidahagije, hashobora gukorwa uduce duto hanyuma agace ko gusudira kagashyirwaho

Gusudira CO2: umusaruro mwinshi, gukoresha ingufu nke, igiciro gito, kurwanya ingese cyane

Gusudira Argon arc: ubujyakuzimu bwo gushonga buto cyane, umuvuduko wo gusudira buhoro, imikorere micye, ikiguzi kinini cyo gukora, inenge zo gushyiramo tungsten, ariko bifite akarusho ko gusudira neza, kandi bishobora gusudira ibyuma bidafite feri, nka aluminiyumu, umuringa, manyeziyumu, nibindi.

⑥ Impamvu zo guhindura uburyo bwo gusudira: gutegura bidahagije mbere yo gusudira, hakenewe ibindi bikoresho. Uburyo bwo kunoza uburyo bwo gusudira nabi. Uburyo bwo gusudira butameze neza.

⑦ Uburyo bwo gukosora ubushyuhe bwo gusudira: Uburyo bwo gukosora umuriro. Uburyo bwo gutigita. Uburyo bwo gukubita. Uburyo bwo gusaza bw'ubukorano.

izindi porogaramu

Intambwe zo gutunganya ibice byo gutunganya mu iduka ry’icyuma ni izi: igeragezwa ry’umusaruro mbere yo gupimwa, igeragezwa ryo gutunganya umusaruro no gukora ibicuruzwa mu byiciro. Mu ntambwe yo gutunganya umusaruro, igomba kuvugana n’abakiriya ku gihe, kandi nyuma yo kubona isuzuma ry’uburyo bitunganywa, umusaruro ushobora gukorwa ku bwinshi.

Ikoranabuhanga ryo gucukura hakoreshejwe laser ni ryo koranabuhanga rya mbere rikoreshwa muri laser mu ikoranabuhanga ryo gutunganya ibikoresho bya laser. Gucukura hakoreshejwe laser mu icupa ry’icyuma muri rusange bikoresha laser zikoresha pulsed, zifite ingufu nyinshi kandi zigafata igihe gito. Ishobora gutunganya imyobo mito ya 1μm. Ikwiriye cyane cyane gutunganya imyobo mito ifite inguni runaka n’ibikoresho bito, kandi ikwiriye no gutunganya imbaraga n’ubukana. Imyobo mito miremire n’imyobo mito mu bice by’ibikoresho birebire cyangwa byoroshye kandi byoroshye.

Laser ishobora gucukura ibice by'umuriro bya turbine ya gaze, kandi ingaruka zo gucukura zishobora gucukura mu cyerekezo cy'ibice bitatu, kandi umubare ushobora kugera ku bihumbi. Ibikoresho bifite imyobo birimo icyuma kitagira umugese, aloyi za nickel-chromium-fer, na aloyi zishingiye kuri HASTELLOY. Ikoranabuhanga ryo gucukura laser ntirigira ingaruka ku miterere y'ibikoresho, kandi biroroshye gukora ikoranabuhanga.

Bitewe n'iterambere ry'ikoranabuhanga ryo gucukura hakoreshejwe laser, imashini ikata laser yageze ku mikorere yayo bwite. Imikoreshereze yayo mu nganda z'ibyuma byahinduye uburyo bwo gutunganya ikoranabuhanga gakondo ry'ibyuma bya sheti, ikora nta muntu ubikora, yongera cyane imikorere myiza, kandi ikora neza muri rusange. Imikorere yayo bwite yateje imbere ubukungu bw'ibyuma bya sheti, kandi yazamuye umusaruro wo gucukura ku rwego rwo hejuru, kandi ingaruka zo gutunganya ziratangaje.

Igihe cyo kohereza: Gicurasi-27-2021