Ukucutshungulwa kwensimbi yeshidi

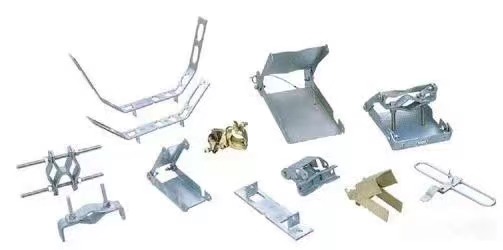

Ukucutshungulwa kwensimbi eshidi kuwubuchwepheshe behabhu okudingeka ochwepheshe bensimbi eshidi babuqonde, futhi kuyinqubo ebalulekile ekwakheni umkhiqizo wensimbi eshidi. Ukucutshungulwa kwensimbi eshidi kuhlanganisa izindlela zendabuko zokusika, ukuvala, ukugoba nokwakha kanye nemingcele yenqubo, kanye nezinhlaka ezahlukene zesakhiwo sedayi esibandayo kanye nemingcele yenqubo, izimiso ezahlukene zokusebenza kwemishini kanye nezindlela zokusebenza, kanye nobuchwepheshe obusha bokucutshungulwa kanye nobuchwepheshe obusha. Ukucutshungulwa kwensimbi eshidi yezingxenye kubizwa ngokuthi ukucutshungulwa kwensimbi eshidi.

Ukucubungula insimbi eshidi kubizwa ngokuthi ukucubungula insimbi eshidi. Ngokukhethekile, isibonelo, ukusetshenziswa kwamapuleti ukwenza amashimoni, imiphongolo yensimbi, amathangi kaphethiloli, amathangi kawoyela, amapayipi okungenisa umoya, izindololwane, izindololwane, izikwele, ama-funnel, njll. Izinqubo eziyinhloko zifaka phakathi ukugunda, ukugoba, ukugoba, ukwakha, ukushisela, ukugoba, njll. Ulwazi oluthile lwejometri. Izingxenye zensimbi eshidi ziyizingxenye ezincane zensimbi eshidi, okungukuthi, izingxenye ezingacutshungulwa ngokunyathela, ukugoba, ukwelula nezinye izindlela. Incazelo ejwayelekile yingxenye enobukhulu obungaguquki ngesikhathi sokucubungula. Ihambisana nokuphonswa, ukuphonswa, izingxenye zomshini, njll.

Ukukhetha izinto

Izinto ezisetshenziswa kakhulu ekucubungulweni kwensimbi eshidi yipuleti eligoqiwe elibandayo (SPCC), ipuleti eligoqiwe elishisayo (SHCC), ipuleti eligoqiwe (SECC, SGCC), ithusi (CU), ithusi elibomvu, ithusi le-beryllium, ipuleti le-aluminium (6061, 5052) 1010, 1060, 6063, i-duralumin, njll.), amaphrofayili e-aluminium, insimbi engagqwali (ubuso besibuko, ubuso obuxutshwe ngebhulashi, ubuso obungacwebezeli), kuye ngendima yomkhiqizo, ukukhetha kwezinto kuhlukile, futhi ngokuvamile kudingeka kucatshangelwe ngokusetshenziswa komkhiqizo kanye nezindleko zawo.

(1) Ishidi eligoqiwe elibandayo i-SPCC, elisetshenziswa kakhulu ekufakeni i-electroplating kanye nokubhaka izingxenye ze-varnish, ezingabizi kakhulu, kulula ukuzibumba, kanye nobukhulu bezinto ≤ 3.2mm.

(2) Ishidi eligoqekile elishisayo i-SHCC, impahla engu-T≥3.0mm, isebenzisa ne-electroplating, izingxenye zopende, ezishibhile, kodwa kunzima ukuzakha, ikakhulukazi izingxenye eziyisicaba.

(3) I-SECC, ishidi le-galvanized le-SGCC. Ibhodi le-electrolytic le-SECC lihlukaniswe ngezinto ze-N kanye nezinto ze-P. Izinto ze-N zisetshenziselwa kakhulu ukwelashwa kwendawo kanye nezindleko eziphakeme. Izinto ze-P zisetshenziselwa izingxenye ezifuthwe.

(4) Ithusi, ikakhulukazi izinto ezisetshenziswayo, ukwelashwa kwendawo yi-nickel plating, i-chrome plating, noma ukungaphathwa kahle, izindleko ziphezulu.

(5) Ipuleti le-aluminium, ngokuvamile lisebenzisa i-surface chromate (J11-A), i-oxidation (i-conductive oxidation, i-chemical oxidation), izindleko eziphezulu, i-silver plating, i-nickel plating.

(6) Amaphrofayili e-aluminium, izinto ezinezakhiwo eziyinkimbinkimbi zesigaba esibanzi zisetshenziswa kabanzi emabhokisini amancane ahlukahlukene. Ukwelashwa kobuso kufana nepuleti le-aluminium.

(7) Insimbi engagqwali, isetshenziswa kakhulu ngaphandle kokwelashwa kwendawo, futhi izindleko ziphezulu.

Izinto ezisetshenziswa kakhulu

- Ishidi lensimbi elihlanganisiwe le-SECC

Isisekelo se-SECC yi-coil yensimbi evamile egoqwe ngokubandayo, eba umkhiqizo ogoqwe ngogesi ngemva kokususa amafutha, ukuphotha, ukufakelwa ngogesi kanye nezinqubo ezahlukahlukene zangemva kokwelashwa emgqeni wokukhiqiza ogoqwe ngogesi. I-SECC ayinazo nje kuphela izakhiwo zemishini kanye nokucutshungulwa okufanayo kweshidi lensimbi eligoqwe ngokubandayo, kodwa futhi inokumelana nokugqwala okuphezulu kanye nokubukeka kokuhlobisa. Iyancintisana kakhulu futhi ingashintshwa emakethe yemikhiqizo kagesi, izinto zasekhaya kanye nefenisha. Isibonelo, i-SECC ivame ukusetshenziswa ezimweni zekhompyutha.

2. Ishidi elivamile eligoqiwe elibandayo i-SPCC

I-SPCC ibhekisela ekugingqikeni okuqhubekayo kwama-ingots ensimbi ngokusebenzisa ama-cold rolling mills abe ama-coil ensimbi noma amashidi anobukhulu obudingekayo. Akukho sivikelo ebusweni be-SPCC, futhi kulula uku-oxidation uma ivezwa emoyeni, ikakhulukazi endaweni enomswakama, ijubane loku-oxidation liyasheshiswa, futhi kuvela ukugqwala okubomvu okumnyama. Ubuso kufanele bupendwe, bufakwe ngogesi noma okunye ukuvikelwa uma kusetshenziswa. I-SPCC ibhekisela ekugingqikeni okuqhubekayo kwama-ingots ensimbi ngokusebenzisa ama-cold rolling mills abe ama-coil ensimbi noma amashidi anobukhulu obudingekayo. Akukho sivikelo ebusweni be-SPCC, futhi kulula uku-oxidation uma ivezwa emoyeni, ikakhulukazi endaweni enomswakama, ijubane loku-oxidation liyasheshiswa, futhi kuvela ukugqwala okubomvu okumnyama. Ubuso kufanele bupendwe, bufakwe ngogesi noma okunye ukuvikelwa uma kusetshenziswa.

3. Ishidi lensimbi elishisiwe elishisayo i-SGCC

Ikhoyili yensimbi egayiwe eshisayo ibhekisela kumkhiqizo oqediwe kancane ngemva kokugoqa nokufaka i-pickling noma ukugoqa okubandayo, okugezwa futhi kucwiliswe njalo ebhavini le-zinc elincibilikisiwe ekushiseni okungaba ngu-460°C, ukuze ishidi lensimbi limbozwe ngesendlalelo se-zinc bese licinywa futhi izinto ze-SGCC ezithambile zibe nzima kunezinto ze-SECC, zinokuguquguquka okubi (gwema ukwakheka kokudweba okujulile), ungqimba lwe-zinc olujiyile, kanye nokushibilika okubi.

4. Insimbi engagqwali i-SUS304

Enye yezinsimbi ezingagqwali ezisetshenziswa kakhulu. Ngenxa yokuthi iqukethe i-Ni (nickel), inokumelana nokugqwala nokushisa okungcono kunensimbi ye-Cr (chromium). Inezakhiwo ezinhle kakhulu zemishini, ayinayo into yokuqinisa ukwelashwa kokushisa, futhi ayinakunwebeka.

5. Insimbi engagqwali i-SUS301

Okuqukethwe kwe-Cr (chromium) kuphansi kunokwe-SUS304, futhi ukumelana nokugqwala akukuhle. Kodwa-ke, ingathola amandla amahle okudonswa kanye nobunzima ekunyathelweni ngemva kokusebenza okubandayo, futhi inokuguquguquka okuhle. Isetshenziswa kakhulu kwiziphethu ze-shrapnel kanye ne-anti-EMI.

Isibuyekezo sokudweba

Ukuze sihlanganise ukugeleza kwenqubo yengxenye, kumele siqale sazi izidingo zobuchwepheshe ezahlukahlukene zomdwebo wengxenye; ukubuyekezwa komdwebo kuyisixhumanisi esibaluleke kakhulu ekuhlanganisweni kokugeleza kwenqubo yengxenye.

(1) Hlola ukuthi imidwebo iphelele yini.

(2) Ubudlelwano phakathi komdwebo nombono, ukuthi ilebula licacile, liphelele, kanye neyunithi yobukhulu.

(3) Ubudlelwano bokuhlanganisa, izilinganiso ezibalulekile zezimfuneko zokuhlanganisa.

(4) Umehluko phakathi kwezinguqulo ezindala nezintsha zehluzo.

(5) Ukuhunyushwa kwezithombe ngezilimi zakwamanye amazwe.

(6) Ukuguqulwa kwamakhodi ethebula.

(7) Impendulo kanye nokuxazulula izinkinga zokudweba.

(8) Izinto.

(9) Izidingo zekhwalithi kanye nezidingo zenqubo.

(10) Ukukhishwa okusemthethweni kwemidwebo kumele kugxivizwe ngesitampu sokulawula ikhwalithi.

Izinyathelo zokuzivikela

Umbono owandisiwe uwumbono wohlelo (2D) osekelwe emdwebweni wezingxenye (3D).

(1) Indlela yokwandisa kufanele ifaneleke, futhi kufanele ibe lula ukonga izinto zokwakha kanye nokucutshungulwa kwazo.

(2) Khetha ngendlela efanele indlela yegebe kanye ne-edging, T=2.0, igebe lingu-0.2, T=2-3, igebe lingu-0.5, kanti indlela ye-edging isebenzisa izinhlangothi ezinde kanye nezinhlangothi ezimfushane (amaphaneli eminyango).

(3) Ukucatshangelwa okunengqondo kobukhulu bokubekezelelana: umehluko ongemuhle uya ekugcineni, umehluko omuhle uya phakathi; usayizi womgodi: umehluko omuhle uya ekugcineni, umehluko ongemuhle uya phakathi.

(4) Isiqondiso se-Burr.

(5) Dweba umbono oqondile ohlangothini lokukhipha, ukugoba kwengcindezi, ukudabula, ukubhoboza amaphuzu aqondile (iphakheji), njll.

(6) Hlola izinto zokwakha kanye nobukhulu bebhodi ukuze kuhambisane nokubekezelelana kobukhulu bebhodi.

(7) Kuma-engeli akhethekile, irediyasi yangaphakathi ye-engeli egobayo (ngokuvamile i-R=0.5) idinga ukugoba nokuvuleka.

(8) Izindawo ezivame ukwenza amaphutha (ukungalingani okufanayo) kufanele zigqanyiswe.

(9) Izithombe ezikhulisiwe kufanele zengezwe lapho kunosayizi abaningi khona.

(10) Indawo okufanele ivikelwe ngokufafaza kumele ikhonjiswe.

Izinqubo zokukhiqiza

Ngokusho komehluko ekwakhiweni kwezingxenye zensimbi ezishidi, ukugeleza kwenqubo kungahluka, kodwa ingqikithi ayidluli amaphuzu alandelayo.

- Ukusika: Kunezindlela ezahlukene zokusika, ikakhulukazi lezi ezilandelayo.

①Umshini wokugunda: Uyinto elula esebenzisa umshini wokugunda ukusika imichilo. Isetshenziswa kakhulu ekulungiseni isikhunta nokulungisa ukwakheka. Izindleko ziphansi, kanti ukunemba kungaphansi kuka-0.2, kodwa ingacubungula imichilo noma amabhlogo kuphela ngaphandle kwemigodi namakhona.

②Ukubhoboza: Isebenzisa ukubhoboza ukukhipha izingxenye ezisicaba ngemva kokuvula izingxenye ezisepuletini ngesinyathelo esisodwa noma ngaphezulu ukwakha izimo ezahlukene zezinto. Izinzuzo zayo amahora amafushane okusebenza, ukusebenza kahle okuphezulu, ukunemba okuphezulu, izindleko eziphansi, futhi ifaneleka ekukhiqizweni ngobuningi. , Kodwa ukuklama isikhunta.

③Ukufaka i-NC CNC engenalutho. Uma ufaka i-NC engenalutho, kufanele uqale ubhale uhlelo lomshini we-CNC. Sebenzisa isofthiwe yokuhlela ukuze ubhale isithombe esidwetshiwe esivuliwe sibe uhlelo olungabonwa umshini wokucubungula umdwebo wedijithali we-NC, ukuze ukwazi ukubhoboza ngayinye epuletini isinyathelo ngesinyathelo ngokwalezi zinhlelo. Isakhiwo siyisiqeshana esiyisicaba, kodwa isakhiwo saso sithinteka yisakhiwo sethuluzi, izindleko ziphansi, kanti ukunemba kungu-0.15.

④Ukusika nge-laser ukusetshenziswa kokusika nge-laser ukusika isakhiwo kanye nesimo sepuleti eliyisicaba epuletini elikhulu eliyisicaba. Uhlelo lwe-laser ludinga ukuhlelwa njengokusika kwe-NC. Lungalayisha izimo ezahlukahlukene eziyinkimbinkimbi zezingxenye eziyisicaba ngezindleko eziphakeme kanye nokunemba okuphansi. 0.1.

⑤Umshini wokusika: Sebenzisa kakhulu amaphrofayili e-aluminium, amashubhu asikwele, amashubhu okudweba, imigoqo eyindilinga, njll., ngezindleko eziphansi kanye nokunemba okuphansi.

2. Umshini wokulinganisa: ukucwila phansi, ukuthepha, ukubhoboza, ukubhoboza.

I-angle ye-counterbore ngokuvamile ingu-120℃, esetshenziselwa ukudonsa ama-rivets, kanti engu-90℃ isetshenziselwa izikulufo ezifakwe emanzini angaphansi kanye nokuthinta imigodi engezansi yamasentimitha.

3. Ukugoqa: Kubizwa nangokuthi ukudweba imigodi nokujika imigodi, okuwukudweba imbobo enkulu kancane emgodini omncane oyisisekelo, bese uyithinta. Icutshungulwa kakhulu ngensimbi encane ukuze kwandiswe amandla ayo kanye nenani lezintambo. , Ukuze ugweme amazinyo ashelelayo, ngokuvamile asetshenziselwa ukujiya kwepuleti elincane, ukugoqa okuvamile okungajulile okuzungeze umgodi, ukujiya akushintshi ngokuyisisekelo, futhi ukujiya kuvunyelwe ukuncishiswa ngo-30-40%, ukuphakama okungu-40 kunokuphakama okujwayelekile kokugoqa okungatholakala. Ukuze uthole ukuphakama okungu-60%, ukuphakama okuphezulu kokugoqa kungatholakala lapho ukuncishiswa kungu-50%. Uma ukujiya kwepuleti kukhulu, njengo-2.0, 2.5, njll., kungacindezelwa ngqo.

4. Ukubhoboza: Kuyinqubo yokucubungula esebenzisa ukwakha isikhunta. Ngokuvamile, ukucubungula ukubhoboza kuhlanganisa ukubhoboza, ukusika ekhoneni, ukumboza, ukubhoboza igobolondo eliyindilinga (iqhubu), ukubhoboza nokuklebhula, ukubhoboza, ukwakha kanye nezinye izindlela zokucubungula. Ukucubungula kudinga ukuba nezindlela zokucubungula ezihambisanayo. Isikhunta sisetshenziselwa ukuqedela imisebenzi, njengokubopha nokumboza isikhunta, isikhunta esiyindilinga, ukuklebhula isikhunta, ukumboza isikhunta, njll. Umsebenzi unaka kakhulu isikhundla kanye nesiqondiso.

5. Ukugoba ngokucindezela: Ngokuphathelene nenkampani yethu, ukugoba ngokucindezela kuhlanganisa kakhulu amantongomane okugoba ngokucindezela, izikulufo, njalo njalo. Umsebenzi uqedwa ngomshini wokugoba ngokucindezela we-hydraulic noma umshini wokubhoboza, okuwagoba ezingxenyeni zensimbi ezishidi, kanye ne-riveting Way, okudingeka ukunaka indlela okuqondiswa ngayo.

6. Ukugoba: Ukugoba kuwukugoba izingxenye eziyisicaba ze-2D zibe izingxenye ze-3D. Ukucubungula kudinga ukuqedwa ngombhede ogoqayo kanye nezimonyo ezigoqayo ezihambisanayo, futhi kunokulandelana okuthile kokugoba. Isimiso siwukuthi ukusika okulandelayo akuphazamisi ukugoba kokuqala, futhi ukuphazamiseka kuzokwenzeka ngemva kokugoba.

Inani lemichilo yokugoba liphindwe kasithupha ubukhulu bepuleti ngaphansi kwe-T=3.0mm ukuze kubalwe ububanzi bomsele, njengokuthi: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Ukuhlukaniswa kwesikhunta sombhede esigobayo, ummese oqondile, isikere (80 ℃, 30 ℃).

Kukhona imifantu lapho ipuleti le-aluminium ligobile. Ububanzi besikhala se-die esingezansi bungandiswa, kanti i-die R engenhla ingandiswa (uku-annealing kungagwema imifantu).

Izinyathelo Zokuqapha Lapho Ugoba: Ⅰ Ukudweba, ukujiya kwepuleti okudingekayo kanye nobuningi; Ⅱ isiqondiso sokugoba; Ⅲ i-engeli yokugoba; Ⅳ usayizi wokugoba; Ⅵ ukubukeka, akukho ukugoba okuvunyelwe ezintweni ezifakwe i-chrome. Ubudlelwano phakathi kokugoba kanye nenqubo yokugoba ingcindezi ngokuvamile buwukuqala kokugoba ingcindezi bese kuba ukugoba, kodwa ezinye izinto zizophazamisa ukugoba kwengcindezi, bese zicindezela kuqala, kanti ezinye zidinga ukugoba-ukugoba-ukugoba-bese kugoba nezinye izinqubo.

7. Ukushisela: Incazelo yokushisela: Ibanga eliphakathi kwama-athomu nama-molecule ezinto ezishiselwe kanye ne-lattice ye-Jingda yakha konke.

①Ukuhlukaniswa: a Ukushisela kwe-Fusion: ukushisela kwe-argon arc, ukushisela kwe-CO2, ukushisela kwegesi, ukushisela ngesandla. b Ukushisela ngengcindezi: ukushisela amabala, ukushisela izinqe, ukushisela kwe-bump. c Ukushisela nge-brazing: ukushisela kwe-chromium kagesi, ucingo lwethusi.

② Indlela yokushisela: ukushisela okuvikelwe yigesi ye-CO2. b Ukushisela i-argon arc. c Ukushisela amabala, njll. d Ukushisela irobhothi.

Ukukhetha indlela yokushisela kusekelwe ezidingweni zangempela kanye nezinto zokwakha. Ngokuvamile, ukushisela okuvikelwe yigesi ye-CO2 kusetshenziselwa ukushisela ipuleti lensimbi; ukushisela i-argon arc kusetshenziselwa ukushisela insimbi engagqwali kanye nepuleti le-aluminium. Ukushisela i-robot kungonga amahora okusebenza futhi kuthuthukise ukusebenza kahle komsebenzi. Futhi ikhwalithi yokushisela, kunciphisa ukuqina komsebenzi.

③ Uphawu lokushisela: Ukushisela i-Δ fillet, Д, ukushisela uhlobo lwe-I, ukushisela uhlobo lwe-V, ukushisela uhlobo lwe-V olulodwa (V) Ukushisela uhlobo lwe-V olunomphetho okhanyayo (V), ukushisela amabala (O), ukushisela ipulaki noma ukushisela izikhala (∏), Ukushisela okunezinsika (χ), ukushisela okunohlangothi olulodwa lwe-V olunomphetho okhanyayo (V), ukushisela okunohlobo lwe-U olunomugqa okhanyayo, ukushisela okunohlobo lwe-J olunomugqa okhanyayo, ukushisela kwesembozo sangemuva, kanye nokushisela ngakunye.

④ Izintambo zomcibisholo nezixhumi.

⑤ Izindlela zokushisela ezingekho kanye nezindlela zokuvimbela.

Ukushisela amabala: uma amandla enganele, kungenziwa amaqhubu bese indawo yokushisela ifakwa

Ukushisela i-CO2: ukukhiqiza okuphezulu, ukusetshenziswa kwamandla aphansi, izindleko eziphansi, ukumelana nokugqwala okunamandla

Ukushisela i-argon arc: ukujula kokuncibilika okungajulile, isivinini sokushisela esihamba kancane, ukusebenza kahle okuphansi, izindleko zokukhiqiza eziphakeme, amaphutha okufakwa kwe-tungsten, kodwa kunenzuzo yekhwalithi enhle yokushisela, futhi kungashisela izinsimbi ezingezona i-ferrous, njenge-aluminium, ithusi, i-magnesium, njll.

⑥ Izizathu zokuguquguquka kokushisela: ukulungiswa okunganele ngaphambi kokushisela, kudingeka izinto ezengeziwe. Inqubo yokuthuthukisa ama-jig okushisela angalungile. Uchungechunge lokushisela alulungile.

⑦ Indlela Yokulungisa Ukuguqulwa Kokushisela: Indlela Yokulungisa Ilangabi. Indlela Yokudlidliza. Indlela Yokubhoboza. Indlela Yokuguga Okwenziwayo.

ezinye izinhlelo zokusebenza

Izinyathelo zokucubungula izingxenye zokucubungula endaweni yokusebenzela yensimbi yilezi: ukuhlolwa kwangaphambi komkhiqizo, ukukhiqizwa kwesilingo sokucubungula umkhiqizo kanye nokukhiqizwa kweqoqo lomkhiqizo. Esinyathelweni sokukhiqiza kwesilingo sokucubungula umkhiqizo, kufanele ixhumane namakhasimende ngesikhathi, futhi ngemva kokuthola ukuhlolwa kokucubungula okuhambisanayo, umkhiqizo ungakhiqizwa ngobuningi.

Ubuchwepheshe bokubhoboza nge-laser buwubuchwepheshe bokuqala obusebenzayo be-laser kubuchwepheshe bokucubungula izinto ze-laser. Ukubhoboza nge-laser endaweni yokusebenzela yensimbi eshidi ngokuvamile kusebenzisa ama-laser ashukunyiswayo, anamandla aphezulu kanye nesikhathi esifushane. Ingacubungula imigodi emincane engu-1μm. Ifaneleka kakhulu ekucubunguleni imigodi emincane ene-engeli ethile kanye nezinto ezincane, futhi ifanele futhi amandla okucubungula kanye nobunzima. Imigodi emincane ejulile kanye nemigodi emincane ezingxenyeni zezinto eziphakeme noma ezibuthakathaka kakhulu nezithambile.

I-laser ingasebenzisa ukubhoboza izingxenye zomlilo ze-turbine yegesi, futhi umphumela wokubhoboza ungasebenzisa isiqondiso esinezinhlangothi ezintathu, futhi inani lingafinyelela izinkulungwane. Izinto ezimboziwe zifaka insimbi engagqwali, ama-alloy e-nickel-chromium-iron, kanye nama-alloy asekelwe ku-HASTELLOY. Ubuchwepheshe bokubhoboza nge-laser abuthinteki yizakhiwo zemishini zento, futhi kulula ukwenza okuzenzakalelayo.

Ngokuthuthuka kobuchwepheshe bokubhoboza nge-laser, umshini wokusika nge-laser uye wafeza ukusebenza okuzenzakalelayo. Ukusetshenziswa embonini yensimbi eshidi kushintshe indlela yokucubungula ubuchwepheshe bensimbi eshidi yendabuko, kwafeza ukusebenza okungenamuntu, kwathuthukisa kakhulu ukusebenza kahle kokukhiqiza, futhi kwafeza yonke inqubo. Ukusebenza okuzenzakalelayo kukhuthaze ukuthuthukiswa komnotho wensimbi eshidi, futhi kuthuthukise umphumela wokubhoboza ezingeni eliphakeme, futhi umphumela wokucubungula uyamangalisa.

Isikhathi sokuthunyelwe: Meyi-27-2021