Kugadziriswa kwesimbi yepepa

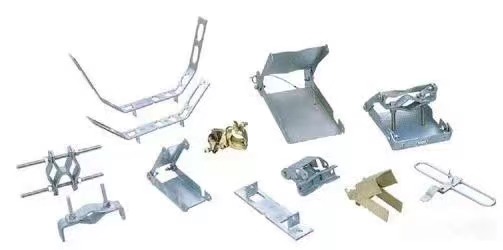

Kugadzira simbi yesimbi inyanzvi yehub iyo nyanzvi dzesimbi yesimbi dzinofanira kunzwisisa, uye ibasa rakakoshawo pakugadzira zvigadzirwa zvesimbi yesimbi. Kugadzira simbi yesimbi yesimbi kunosanganisira nzira dzekucheka, kubvisa, kukotama nekugadzira uye maparamendi ekugadzirisa, pamwe chete nematanho akasiyana-siyana ekugadzira nekugadzira zvinhu zvinotonhora, misimboti yakasiyana-siyana yekushanda kwemidziyo uye nzira dzekushanda, uye tekinoroji itsva yekuisa zvimiti uye tekinoroji itsva. Kugadzira simbi yesimbi yezvikamu kunonzi processing yesimbi yesimbi yesimbi.

Kugadzira simbi inonzi sheet metal processing. Semuenzaniso, kushandiswa kwemaplate kugadzira chimney, simbi, matangi emafuta, matangi emafuta, mapaipi emhepo, magokora, magokora, masikweya, mafunnel, nezvimwewo. Maitiro makuru anosanganisira kucheka, kukotama, kukotama, kugadzira, kusveta, riveting, nezvimwewo. Ruzivo rwakadzama rwejometri. Zvikamu zvesimbi izvikamu zvitete zvesimbi, kureva kuti, zvikamu zvinogona kugadziriswa nekudzvanya, kukotama, kutambanudza nedzimwe nzira. Tsanangudzo yakajairika chikamu chine ukobvu hunogara huripo panguva yekugadzirisa. Inoenderana ne castings, forgings, machining parts, nezvimwewo.

Sarudzo yezvinhu

Zvinhu zvinowanzoshandiswa mukugadzirisa simbi dzakagadzirwa nesimbi zvinoti: plate yakaputirwa inotonhora (SPCC), plate yakaputirwa inopisa (SHCC), galvanized plate (SECC, SGCC), copper (CU) brass, red copper, beryllium copper, aluminium plate (6061, 5052) 1010, 1060, 6063, duralumin, nezvimwewo), aluminium profiles, stainless steel (girazi pamusoro, brushed surface, matte surface), zvichienderana nebasa rechigadzirwa, sarudzo yezvinhu zvakasiyana, uye zvinowanzoda kutariswa kubva pakushandiswa kwechigadzirwa uye mutengo wacho.

(1) Cold rolled sheet SPCC, inonyanya kushandiswa pakugadzira nekugadzira zvikamu zvevarnish, inodhura zvishoma, iri nyore kugadzira, uye ukobvu hwechinhu ≤ 3.2mm.

(2) SHCC yakaputirwa nemoto, yakagadzirwa neT≥3.0mm, inoshandisawo electroplating, zvikamu zvependi, zvinodhura zvishoma, asi zvakaoma kugadzira, kunyanya zvikamu zvakati sandara.

(3) SECC, jira reSGCC rakarukwa. Bhodhi remagetsi reSECC rakakamurwa kuita zvinhu zveN uye zvinhu zveP. Zvinhu zveN zvinonyanya kushandiswa pakurapa pamusoro uye zvinodhura zvakanyanya. Zvinhu zveP zvinoshandiswa pakushandisa zvikamu zvinopfapfaidzwa.

(4) Mhangura, inonyanya kushandiswa nezvinhu zvinofambisa mvura, mushonga wepamusoro unosanganisira nickel plating, chrome plating, kana kuti hapana mushonga, mutengo wakakwira.

(5) Aruminiyamu ndiro, inowanzoshandisa chromate yepamusoro (J11-A), oxidation (oxidation yekufambisa, oxidation yemakemikari), mutengo wakakwira, sirivha, nickel plating.

(6) Mapurofayi eAruminiyamu, zvinhu zvine maumbirwo akaomarara ezvikamu zvakasiyana-siyana zvinoshandiswa zvakanyanya mumabhokisi akasiyana-siyana. Kugadziriswa kwepamusoro kwakafanana neplate yearuminiyamu.

(7) Simbi isina ngura, inonyanya kushandiswa isina kugadziriswa pamusoro, uye mutengo wayo wakakwira.

Zvinhu zvinoshandiswa kazhinji

- Sheti resimbi rakakamurwa SECC

Chikamu cheSECC isimbi yakaputirwa nechando, iyo inova chigadzirwa chakaputirwa nemagetsi mushure mekubviswa mafuta, kuputirwa, kuputirwa nemagetsi uye maitiro akasiyana-siyana ekugadzirisa mushure mekubvisa mafuta, kuputirwa, kuputirwa nemagetsi uye maitiro akasiyana-siyana ekugadzirisa mushure mekugadzirwa kwemagetsi. SECC haina chete hunhu hwemakanika uye kugona kwakafanana kwesimbi yakaputirwa nechando, asiwo inodzivirira ngura zvakanyanya uye chitarisiko chekushongedza. Inokwikwidzana zvikuru uye inogona kutsiviwa mumusika wezvigadzirwa zvemagetsi, midziyo yemumba nefenicha. Semuenzaniso, SECC inowanzoshandiswa mumakesi emakombiyuta.

2. SPCC yakaputirwa nechando

SPCC inoreva kutenderedzwa kwesimbi kuburikidza nemabhandi anotonhorera anopinda musimbi kana mapepa ane ukobvu hunodiwa. Hapana dziviriro pamusoro peSPCC, uye inooxidized zviri nyore kana yaiswa mumhepo, kunyanya munzvimbo ine hunyoro, kumhanya kweoxidation kunowedzera, uye ngura tsvuku yakasviba inoonekwa. Pamusoro payo panofanira kupendwa, kuiswa nemagetsi kana kumwe kudzivirirwa kana ichishandiswa. SPCC inoreva kutenderedzwa kwesimbi kuburikidza nemabhandi anotonhorera anopinda musimbi kana mapepa ane ukobvu hunodiwa. Hapana dziviriro pamusoro peSPCC, uye inooxidized zviri nyore kana yaiswa mumhepo, kunyanya munzvimbo ine hunyoro, kumhanya kweoxidation kunowedzera, uye ngura tsvuku yakasviba inoonekwa. Pamusoro payo panofanira kupendwa, kuiswa nemagetsi kana kumwe kudzivirirwa kana ichishandiswa.

3. Sheti resimbi rakabatidzwa rinopisa SGCC

Coil yesimbi yakagadzika inopisa inoreva chigadzirwa chakapedzwa mushure mekuputirwa nekupisa nekuputirwa kana kuputirwa nechando, icho chinogezwa uye chinogara chichinyudzwa mubhavhu rezinc rakanyungudutswa patembiricha inosvika 460°C, kuitira kuti jira resimbi rifukidzwe nezinc layer uye robva radzimwa uye zvinhu zveSGCC zvinogara zvakaoma kupfuura zvinhu zveSECC, hazvina ductility yakanaka (dzivisa dhizaini yekudhirowa yakadzika), zinc layer yakakora, uye kusawirirana kwakashata.

4.Simbi isina ngura SUS304

Imwe yesimbi dzisina ngura dzinonyanya kushandiswa. Nekuti ine Ni (nickel), ine simba rekudzivirira ngura uye kupisa zviri nani kupfuura Cr (chromium) steel. Ine hunhu hwakanaka kwazvo hwemakanika, haina kupisa kunoomesa, uye haina kusimba.

5.Simbi isina ngura SUS301

Huremu hweCr (chromium) hwakaderera pane hweSUS304, uye kuramba ngura kwakaderera. Zvisinei, inogona kuwana simba rakanaka rekudhonza uye kuomarara pakutsika mushure mekushanda muchitonhora, uye ine kusimba kwakanaka. Inonyanya kushandiswa kumasprings e shrapnel uye anti-EMI.

Ongororo yemifananidzo

Kuti tiunganidze maitikiro echikamu, tinofanira kutanga taziva zvinodiwa zvehunyanzvi zvechikamu; ongororo yedhirowa ndiyo inonyanya kukosha mukuunganidza maitikiro echikamu.

(1) Tarisa kana mifananidzo yacho yakakwana.

(2) Hukama huripo pakati pemufananidzo nemaonero, kana zita racho rakajeka, rakakwana, uye chiyero chehukuru.

(3) Hukama hwemuunganidzi, zviyero zvakakosha zvezvinodiwa muunganidzi.

(4) Musiyano uripo pakati pemavhezheni ekare neatsva.

(5) Kushandurwa kwemifananidzo mumitauro yekune dzimwe nyika.

(6) Kushandurwa kwemakodhi etafura.

(7) Mhinduro uye kugadzirisa matambudziko ekudhirowa.

(8) Nyaya.

(9) Zvinodiwa zvemhando yepamusoro uye zvinodiwa pakuita basa.

(10) Kuburitswa kwemifananidzo zviri pamutemo kunofanirwa kudhindwa nechisimbiso chekudzora mhando.

Zvekungwaririra

Maonero akawedzerwa ndiwo maonero ehurongwa (2D) zvichibva pamufananidzo wechikamu (3D).

(1) Nzira yekuwedzera inofanira kunge yakakodzera, uye inofanira kunge iri nyore kuchengetedza zvinhu uye kugona kugadzikiswa.

(2) Sarudza zvine musoro nzira yepakati nepakati, T=2.0, musiyano uri 0.2, T=2-3, musiyano uri 0.5, uye nzira yepakati inoshandisa mativi marefu nemativi mapfupi (mapaneru emusuwo).

(3) Kufunga zvine musoro nezvezvikamu zvekushivirira: musiyano uripo unoenda kumagumo, musiyano uripo unoenda hafu; saizi yeburi: musiyano uripo unoenda kumagumo, musiyano uripo unoenda hafu.

(4) Kutungamira kweBurr.

(5) Dhirowa mufananidzo wepakati pechikamu wakananga kunobviswa, kudzvanywa kwesimba, kubvarura, kupwanya nzvimbo dzakapinza (pakeji), nezvimwewo.

(6) Tarisa zvinhu uye ukobvu hwebhodhi zvichienderana nekukwanisa kwebhodhi kukwira.

(7) Kune makona akakosha, radius yemukati yekona inokombama (kazhinji R=0.5) inofanira kuchinjika uye kuvhurwa.

(8) Nzvimbo dzinokanganisa (dzisina kuenzana kwakafanana) dzinofanira kuratidzwa pachena.

(9) Mifananidzo yakakura inofanira kuwedzerwa kana paine saizi dzakawanda.

(10) Nzvimbo inofanira kuchengetedzwa nekupfapfaidza inofanira kuratidzwa.

Maitiro ekugadzira

Zvichienderana nemusiyano uripo muchimiro chezvikamu zvesimbi, kuyerera kwemaitiro kunogona kusiyana, asi huwandu hwese hahupfuure mapoinzi anotevera.

- Kucheka: Kune nzira dzakasiyana-siyana dzekucheka, kunyanya nzira dzinotevera.

①Muchina wekuveura: Chinhu chiri nyore kushandisa muchina wekuveura zvidimbu. Chinonyanya kushandiswa pakugadzira nekuputira chakuvhuvhu. Mutengo wacho wakaderera, uye kururama kwacho kuri pasi pe0.2, asi chinongogona kugadzirisa zvidimbu kana mabhuroko pasina maburi uye pasina makona.

②Kubaya: Inoshandisa kubaya kuburitsa zvikamu zvakati sandara mushure mekuvhura zvikamu zviri mundiro nedanho rimwe kana kupfuura kuti igadzire maumbirwo akasiyana-siyana ezvinhu. Zvakanakira zvayo ndezvekushanda kwemaawa mashoma, kushanda zvakanaka, kunyatsorongeka, mutengo wakaderera, uye yakakodzera kugadzirwa kwakawanda. , Asi kugadzira mold.

③NC CNC blanking. Kana NC blanking, unofanira kutanga wanyora chirongwa cheCNC machining. Shandisa software yeprogramming kunyora mufananidzo wakavhurwa kuita purogiramu inogona kuzivikanwa nemuchina weNC digital drawing processing, kuitira kuti igone kupinza chimwe nechimwe paplate nhanho nhanho zvichienderana nemapurogiramu aya. Chimiro chacho chidimbu chakati sandara, asi chimiro chacho chinokanganiswa nemagadzirirwo echishandiso, mutengo wakaderera, uye kururama kwacho i0.15.

④Kucheka neLaser kunoshandiswa kucheka neLaser kucheka chimiro nechimiro cheplate yakatsetseka paplate hombe yakatsetseka. Chirongwa cheLaser chinofanira kurongwa seNC cutting. Chinogona kurodha maumbirwo akasiyana-siyana akaomarara ezvikamu zvakatsetseka nemutengo wakakwira uye kunyatsorongeka kwakaderera. 0.1.

⑤Muchina wekucheka: Shandisa ma profiles earuminiyamu, machubhu akaenzana, machubhu ekudhirowa, mapuranga akatenderera, nezvimwewo, nemari yakaderera uye kunyatsoita zvinhu nemazvo.

2. Kugadzirira: kunyura pasi, kugonya, kukwesha, kuboora.

Kona yemuchina wekudzivirira simbi inowanzova 120℃, inoshandiswa pakudhonza ma rivets, uye 90℃ inoshandiswa pakudhonza screws dzinoiswa pasi pemvura uye kubata maburi epasi neinchi.

3. Kupinza: Inonziwo kudhonza maburi uye kutenderedza maburi, zvinoreva kudhonza gomba rakakura zvishoma paburi diki repasi, wobva waribaya. Rinonyanya kugadzirwa nesimbi yakatetepa kuti riwedzere simba raro uye huwandu hweshinda. , Kuti udzivise mazino anotsvedza, anowanzo shandiswa pakukora kweplate yakatetepa, kutenderedza gomba zvisina kudzika, ukobvu hwacho hauchinji, uye ukobvu hwacho hunobvumirwa kutetepa ne30-40%, 40-yakakwirira kupfuura kukwirira kweflangi kwakajairika kunogona kuwanikwa. Kana kukwirira kwe60%, kukwirira kweflangi kwakakwirira kunogona kuwanikwa kana kutetepa kuri 50%. Kana ukobvu hweplate hwakakura, senge 2.0, 2.5, nezvimwewo, hunogona kuroverwa zvakananga.

4. Kubaya: Inzira yekugadzirisa inoshandisa kugadzira chakuvhuvhu. Kazhinji, kugadzirisa kunosanganisira kubaya, kucheka pakona, kubvisa chinhu, kubaya convex hull (bump), kurova nekubvarura, kurova, kugadzira nedzimwe nzira dzekugadzirisa. Kugadzira kunofanirwa kuve nenzira dzinoenderana dzekugadzirisa. Chiumbwa chinoshandiswa kupedzisa mabasa, akadai sekurova nekubaya chiumbwa, convex molds, kubvarura chiumbwa, kubaya chiumbwa, kugadzira chakuvhuvhu, nezvimwewo. Kushanda kwacho kunonyanya kutarisa nzvimbo negwara.

5. Kudzvanya pressure riveting: Kana tichitarisa kambani yedu, kudzvanya pressure riveting kunosanganisira nzungu dzinodzvanya pressure riveting, screws, nezvimwewo. Basa racho rinoitwa nemuchina we hydraulic pressure riveting kana muchina we punching, uchidzidzvanya muzvikamu zvesimbi, uye nzira yekudzidzvanya, inofanira kutarisisa divi rayo.

6. Kukombama: Kukombama kunoreva kupeta zvikamu zve2D zvakati sandara kuita zvikamu zve3D. Kugadzira kunofanirwa kuitwa nemubhedha unopetwa uye maforoma anokombama anoenderana, uye kunewo kurongwa kwekukombama kwakati. Nheyo ndeyekuti kucheka kunotevera hakukanganisi kukombama kwekutanga, uye kukanganiswa kuchaitika mushure mekukombama.

Huwandu hwezvimedu zvinokotama hunopfuura katanhatu ukobvu hweplate iri pasi paT=3.0mm kuti uverenge upamhi hwemugero, hwakadai se: T=1.0, V=6.0 F=1.8, T=1.2, V=8, F=2.2, T=1.5, V =10, F=2.7, T=2.0, V=12, F=4.0.

Kurongwa kwechimiro chemubhedha chinokotama, banga rakatwasuka, scimitar (80 ℃, 30 ℃).

Pane mitswe kana ndiro yearuminiyamu yakakombama. Upamhi hwenzvimbo yepasi pedhie inogona kuwedzerwa, uye dhie yepamusoro R inogona kuwedzerwa (kunyungudutsa kunogona kudzivirira mitswe).

Kungwarira pakukotama: Ⅰ Kudhirowa, ukobvu hweplate hunodiwa uye huwandu; Ⅱ gwara rekukotama; Ⅲ kona yekukotama; Ⅳ saizi yekukotama; Ⅵ chitarisiko, hapana makwinya anotenderwa pane zvinhu zvakaiswa chrome. Hukama huripo pakati pekukotama nemaitiro ekuita riveting yekumanikidza kazhinji ndiyo yekutanga riveting yekumanikidza uye yekukotama, asi zvimwe zvinhu zvinokanganisa riveting yekumanikidza, uye wobva wadzvanya kutanga, uye zvimwe zvinoda kukotama-kumanikidzwa riveting-zobva wakotama nezvimwe zvinhu.

7. Kukwesha: Tsanangudzo yekukwesha: Chinhambwe chiri pakati pemaatomu nemamorekuru echinhu chakakweshaniswa neJingda lattice chinoumba zvese.

①Kupatsanura: a Kubatanidza: argon arc welding, CO2 welding, gas welding, manual welding. b Kubatanidza nepressure: kusanganisa spot, kusanganisa butt, kusanganisa bump. c Brazing: kusanganisa chromium yemagetsi, waya yemhangura.

② Nzira yekuwedera: welding ine CO2 gas shielded. b Welding yeArgon arc. c Welding yeSpot, nezvimwewo. d Welding yeRobot.

Sarudzo yenzira yekuwedera inobva pane zvinodiwa chaizvo nezvinhu. Kazhinji, welding yeCO2 inoshandiswa pakuwedera plate yesimbi; welding yeargon arc inoshandiswa pakuwedera simbi isina ngura uye aluminium plate. Welding yemarobhoti inogona kuchengetedza maawa evashandi uye kuvandudza kushanda zvakanaka. Uye kunaka kwekuwedera, kunoderedza simba rebasa.

③ Chiratidzo chekuwelda: Δ fillet welding, Д, I type welding, V type welding, single side V type welding (V) V type welding ine blunt edge (V), spot welding (O), plug welding kana slot welding (∏), Crimp welding (χ), single-sided V-shaped welding ine blunt edge (V), U-shaped welding ine blunt, J-shaped welding ine blunt, back cover welding, uye yega yega welding.

④ Waya dzemiseve nezvinobatanidza.

⑤ Kusavapo kwekunamira uye matanho ekudzivirira.

Kupinza nzvimbo: kana simba risina kukwana, mabumps anogona kugadzirwa uye nzvimbo yekupinza inoiswa

Kuwedera kweCO2: kubereka kwakanyanya, kushandiswa kwesimba shoma, mutengo wakaderera, kuramba ngura kwakasimba

Kunyungudutsa kweArgon arc: kudzika kwekunyunguduka kushoma, kumhanya kwekunyungudutsa kunononoka, kushanda zvishoma, mutengo wakakwira wekugadzira, zvikanganiso zvekubatanidza tungsten, asi zvine mukana wemhando yepamusoro yekunyungudutsa, uye zvinogona kunyungudutsa simbi dzisina ferrous, dzakadai sealuminium, copper, magnesium, nezvimwewo.

⑥ Zvikonzero zvekuchinjika kwewelding: kugadzirira kusina kukwana usati waisa welding, zvimwe zvinodiwa. Maitiro ekuvandudza majig ekuisa welding asina kunaka. Kutevedzana kwewelding hakuna kunaka.

⑦ Nzira Yekugadzirisa Kuchinja KwemaWelding: Nzira Yekugadzirisa Moto. Nzira yekudedera. Nzira yekurova nenyundo. Nzira yekuchekerera yakagadzirwa.

mamwe maapplication

Matanho ekugadzirisa zvikamu zvekugadzirisa mu sheet metal workshop ndeaya: bvunzo yekutanga kwechigadzirwa, bvunzo yekugadzira chigadzirwa uye kugadzirwa kweboka rezvigadzirwa. Mudanho rekugadzira bvunzo yekugadzirisa chigadzirwa, chinofanira kutaurirana nevatengi nenguva, uye mushure mekuwana kuongororwa kwekugadzirisa kwakakodzera, chigadzirwa chinogona kugadzirwa zvakanyanya.

Tekinoroji yekuboora nelaser ndiyo tekinoroji yekutanga inoshanda yelaser muhunyanzvi hwekugadzirisa zvinhu zvelaser. Kuboora nelaser muworkshop yesimbi yepepa kunowanzo shandisa malaser ane simba rakawanda uye nguva pfupi. Inogona kugadzirisa maburi madiki e1μm. Yakakodzera zvakanyanya kugadzirisa maburi madiki ane kona yakati uye zvinhu zvakatetepa, uye yakakodzerawo kugadzirisa simba nekuomarara. Maburi madiki akadzika uye maburi madiki muzvikamu zvezvinhu zvakakwirira kana zvakanyanya kuputsika uye zvakapfava.

Laser inogona kuburitsa zvikamu zvemoto zvegasi turbine, uye mhedzisiro yekuburitsa inogona kuburitsa divi remativi matatu, uye nhamba yacho inogona kusvika zviuru. Zvinhu zvakaboorwa zvinosanganisira simbi isingatsvedzeri, nickel-chromium-iron alloys, uye HASTELLOY-based alloys. Tekinoroji yekuburitsa laser haikanganisike nehunhu hwemuchina wechinhu chacho, uye zviri nyore kuita otomatiki.

Nekuvandudzwa kwetekinoroji yekuboora nelaser, muchina wekucheka nelaser wave kushanda otomatiki. Kushandiswa muindasitiri yesimbi kwakachinja nzira yekugadzirisa tekinoroji yechinyakare yesimbi, kwakabatsira kushanda pasina mutyairi, kwakavandudza zvikuru mashandiro ekugadzira, uye kwakabatsira maitiro ese. Kushanda otomatiki kwakasimudzira kukura kwehupfumi hwesimbi, uye kwakavandudza mhedzisiro yekubaya kusvika padanho repamusoro, uye mhedzisiro yekugadzirisa inoshamisa.

Nguva yekutumira: Chivabvu-27-2021