Kev Txhais Lus:

Ib qho txheej txheem ua haujlwm txias rau cov hlau phaj, feem ntau muab faib ua shearing, xuas nrig ntaus, khoov, riveting, pwm tsim, vuam, thiab lwm yam. Cov phaj siv feem ntau suav nrog cov phaj kub dov, cov phaj pickled, cov phaj txias dov, cov phaj galvanized, cov phaj tooj liab, cov phaj txhuas, cov ntawv txhuas, cov phaj stainless hlau, thiab lwm yam.

Cov txheej txheem ua haujlwm feem ntau:

1. Kev ua cov hlau phaj los ntawm lub tshuab CNC punching, CNC bending tshuab, laser txiav tshuab, shearing tshuab thiab lwm yam khoom siv, uas feem ntau yog siv rau cov qauv thiab cov khoom me me.

2. Lub phaj raug ua los ntawm lub pwm ruaj khov ntawm lub tshuab xuas nrig lossis nias thiab lwm yam khoom siv. Qhov ceev yog ceev thiab tus nqi qis, tab sis tus nqi ntawm lub pwm siab, kev teeb tsa thiab hloov pauv yog siv sijhawm ntau, thiab nws feem ntau yog siv rau kev tsim khoom loj.

Cov txheej txheem ua cov hlau ntawv:

1. Kev txiav: pwm, laser txiav, shearing lossis xuas nrig ntaus.

2. Kev tsim: khoov, tsim pwm.

3. Lwm yam kev ua: nias riveting, riveting lossis tapping.

4. Vuam: arc vuam (TIG / MIG), tsis kam vuam.

5. Kev kho qhov chaw: hmoov txheej, electrophoresis, electroplating, thiab lwm yam.

Cov khoom siv dav dav thiab cov txheej txheem kev taw qhia

Tshuab txiav:

Tshuab qhia:

Lub tshuab txiav siv cov hniav sab saud txav mus los thiab cov hniav qis ruaj khov, thiab siv qhov sib txawv ntawm cov hniav kom tsim nyog los siv lub zog txiav rau cov ntawv hlau ntawm ntau yam tuab kom ua rau cov ntawv tawg thiab sib cais raws li qhov loj me xav tau.

Kev taw qhia txog txheej txheem:

Siv rau kev txiav cov strips, nws feem ntau yog siv rau kev npaj cov txheej txheem pwm blanking, lossis blanking cov khoom yooj yim nrog cov duab ib txwm muaj. Ceev ceev, pheej yig, tsis muaj kev raug, tsuas yog tuaj yeem ua cov strips lossis blocks tsis muaj qhov thiab ces kaum.

Tshuab txiav laser:

Tshuab qhia:

Siv lub laser muaj zog heev los ua kom cov khoom siv uas yuav tsum tau txiav tawm. Cov khoom siv raug ua pa kom tsim tau ib lub qhov, thiab lub teeb txav mus los ua ib qho kev txiav. Txiav tawm cov qauv ntawm qhov khoom. Yuav tsum sau cov kev pab cuam laser. Nws tuaj yeem txiav ntau yam khoom nrog cov duab nyuaj. Kev ua haujlwm raug siab. Feem ntau siv rau kev tsim cov qauv lossis ntau yam khoom me me.

Kev taw qhia txog txheej txheem:

Lub taub hau laser txiav yog me heev, feem ntau qis dua 0.2MM. Thaum txiav cov hlau carbon phaj qis dua 3 hli, qhov kev kam rau qhov deb ntawm qhov chaw tuaj yeem tswj tau hauv 0.05MM, qhov kev kam rau contour tuaj yeem tswj tau hauv 0.1MM, thiab qhov roughness ntawm qhov chaw tuaj yeem ncav cuag Ra 12.5. Lub laser yuav tawm cov cim rau ntawm qhov chaw txiav. Lub phaj tuab dua, qhov pom tseeb dua.

Cov yam cuam tshuam rau kev txiav laser:

Qhov me me ntawm qhov chaw txiav laser, qhov me me ntawm qhov txiav, qhov siab dua qhov tseeb;

Qhov siab dua qhov kev tso kawm raug ntawm lub rooj ua haujlwm, qhov siab dua qhov kev txiav laser raug;

Daim ntawv tuab dua, qhov qis dua qhov tseeb ntawm kev txiav laser thiab qhov phem dua qhov roughness ntawm qhov chaw;

Nrog tib lub thickness, qhov precision ntawm lub phaj hlau yog siab dua li lub phaj txhuas, thiab qhov txiav nto yog smoother;

CNC tshuab xuas nrig ntaus:

Tshuab qhia:

Ib lub tshuab xuas nrig ntaus tsis siv neeg uas muaj kev tswj tus lej. Los ntawm CNC programming cov lus qhia, tswj kev ua haujlwm ntawm cov xuas nrig ntaus thiab tsim cov khoom.

Kev taw qhia txog txheej txheem:

Los ntawm kev sib xyaw ua ke ntawm cov pwm yooj yim, ntau yam kev sib tshuam nyuaj thiab cov ntu ncab ntiav tuaj yeem ua tiav ib zaug. Nws tuaj yeem ua tiav cov qhov loj puag ncig, cov qhov plaub fab, cov qhov duav thiab ntau yam duab ntawm cov duab nkhaus. Qhov no kuj tuaj yeem ua tiav los ntawm cov txheej txheem tshwj xeeb, xws li cov ntaub thaiv qhov rais, cov txee saum toj, cov qhov flanging, cov tav, embossing, thiab lwm yam.

CNC tshuab stamping:

Tshuab qhia:

Lub tshuab stamping yog lub tshuab ua haujlwm siab. Lub tshuab stamping thiab pwm siv lub zog sab nraud rau cov phaj, cov kab txaij, cov kav dej thiab cov profile kom ua rau cov yas deformation lossis sib cais, kom tau txais cov duab thiab qhov loj me uas xav tau ntawm txoj kev tsim khoom.

Kev taw qhia txog txheej txheem:

Los ntawm cov pwm, koj tuaj yeem ua tau blanking, punching, forming, stretching, trimming, fine blanking, shaping, riveting thiab extrusion. Qhov tseeb ntawm kev ua tiav nyob ntawm pwm thiab cov khoom siv. Lub sijhawm hloov pwm thiab kev kho pwm ntev dua. Tus nqi pwm siab. Haum rau cov khoom loj.

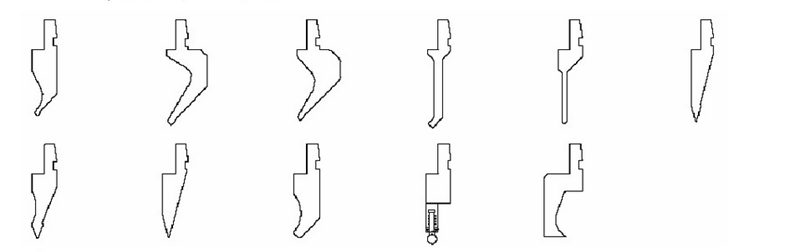

CNC tshuab khoov:

Tshuab qhia:

Cov khoom siv rau kev khoov cov phaj nyias nyias los ntawm cov pwm. Kev ua haujlwm yooj yim, thiab cov khoom ua haujlwm nrog phab ntsa sab tuaj yeem tsim tau. Ceev ceev, raug siab, thiab nws muaj lub luag haujlwm them rov qab tsis siv neeg.

Cov duab ntawm lub pwm khoov (pwm sab saud):

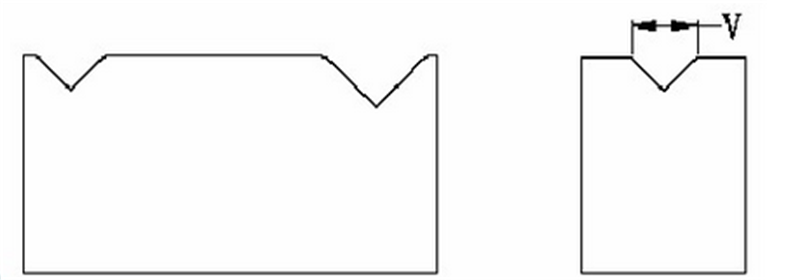

Cov duab V groove (pwm qis dua):

Tshuab vuam:

Tshuab qhia:

Lub tshuab vuam tam sim ntawd hloov lub zog hluav taws xob mus ua cua sov. Nws tuaj yeem txuas cov khoom siv hlau tib yam tam sim ntawd (kuj tseem tuaj yeem txuas cov hlau sib txawv, tab sis txoj kev vuam txawv) mus tas li.

Kev taw qhia txog txheej txheem:

Cov txheej txheem vuam feem ntau hauv cov hlau ntawv yog vuam hlau, vuam yaj thiab vuam laser. Kev vuam laser yog qhov tsim nyog rau cov phaj nyias thiab cov khoom uas xav tau qhov chaw siab. AC welder vuam cov khoom txhuas. DC vuam tshuab vuam hlau, stainless hlau, thiab lwm yam

If you have sheet metal or other metal product fabrication demands, please contact with us freely. We will quote you. Maybe you meet some problem or questions during fabrication or design, also can send into sales1@shhofen.com for help. We are glad to help you.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-20-2020