Incazelo:

Inqubo ebanzi yokusebenza ngokubanda kwepuleti lensimbi, ehlukaniswe kakhulu ukucheba, ukubhoboza, ukugoba, ukugoba, ukwakha isikhunta, ukushisela, njll. Amapuleti asetshenziswa kakhulu afaka amapuleti ashisiwe ashisayo, amapuleti afakwe ukhilimu, amapuleti aqinisiwe abandayo, amapuleti agqitshiwe, amapuleti ethusi, amapuleti e-aluminium, amaphrofayili e-aluminium, amapuleti ensimbi engagqwali, njll.

Izindlela zokucubungula ezivamile:

1. Ukucutshungulwa kwamapuleti ngensimbi yeshidi ngomshini wokubhoboza we-cnc, umshini wokugoba we-cnc, umshini wokusika nge-laser, umshini wokugunda kanye neminye imishini, esetshenziswa kakhulu ekukhiqizeni amasampula kanye neqembu elincane.

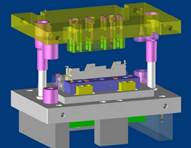

2. Ipuleti licutshungulwa ngesikhunta esiqinile ku-punch noma press kanye neminye imishini. Ijubane liyashesha futhi izindleko ziphansi, kodwa izindleko zesikhunta ziphezulu, ukufakwa nokushintshwa kudla isikhathi, futhi lisetshenziswa kakhulu ekukhiqizweni ngobuningi.

Inqubo yokucubungula izingxenye zensimbi:

1. Ukusika: isikhunta, ukusika nge-laser, ukugunda noma ukubhoboza.

2. Ukwakha: ukugoba, ukwakha isikhunta.

3. Okunye ukucubungula: ukugoba ngengcindezi, ukugoba nge-riveting noma ukuthepha.

4. Ukushisela: ukushisela i-arc (TIG/MIG), ukushisela ukumelana.

5. Ukwelashwa kwendawo: ukumbozwa ngempuphu, i-electrophoresis, i-electroplating, njll.

Imishini evamile kanye nokwethulwa kwenqubo

Umshini wokugunda izinwele:

Isingeniso somshini:

Umshini wokugunda usebenzisa i-blade ephezulu ehambayo kanye ne-blade engezansi eqinile, futhi usebenzisa igebe elifanele le-blade ukufaka amandla okugunda kumashidi ensimbi anobukhulu obuhlukahlukene ukuze amashidi aqhekeke futhi ahlukane ngokobukhulu obudingekayo.

Isingeniso senqubo:

Isetshenziselwa ukusika imichilo, isetshenziswa kakhulu ekulungiseleleni ukucutshungulwa kokumboza ngodayi, noma ukumboza izingxenye ezilula ezinezimo ezijwayelekile. Isivinini esisheshayo, izindleko eziphansi, ukunemba okuphansi, ingacubungula imichilo noma amabhlogo kuphela ngaphandle kwemigodi namakhona.

Umshini wokusika nge-laser:

Isingeniso somshini:

Sebenzisa i-laser enamandla aphezulu ukuze ukhanyisele izinto ezizosikwa. Izinto ziyashiswa ukuze kudalwe umgodi, bese ugongolo luhamba ukuze lwakhe uqhekeko. Sika ukuma kwesakhiwo sengxenye. Kudingeka ubhale uhlelo lwe-laser. Ingasika izingxenye ezahlukahlukene ezinezimo eziyinkimbinkimbi. Ukunemba okuphezulu. Isetshenziswa kakhulu ekukhiqizeni amasampula noma izinhlobo eziningi zomkhiqizo omncane.

Isingeniso senqubo:

Ububanzi bomsebe wokusika nge-laser buncane kakhulu, ngokuvamile bungaphansi kuka-0.2MM. Uma usika amapuleti ensimbi yekhabhoni ngaphansi kuka-3 mm, ukubekezelela ibanga eliphakathi kwembobo kungalawulwa ngaphakathi kuka-0.05MM, ukubekezelela kwe-contour kungalawulwa ngaphakathi kuka-0.1MM, kanti ubulukhuni bomphezulu bungafinyelela ku-Ra 12.5. I-laser izoshiya amamaki ebusweni bokusika. Uma ipuleti likhudlwana, kulapho libonakala khona.

Izici ezithonya ukusika nge-laser:

Uma indawo yokusika nge-laser incane, ucezu luncane, ukunemba kuyanda;

Uma ukunemba kokubeka kwetafula lokusebenza kuphakeme, kulapho ukunemba kokusika nge-laser kukhuphuka khona;

Uma ishidi lijiyile, ukunemba kokusika nge-laser kwehla futhi ukujiya kobuso kubi kakhulu;

Ngobukhulu obufanayo, ukunemba kwepuleti lensimbi kuphakeme kunepuleti le-aluminium, futhi indawo yokusika ibushelelezi;

Umshini wokushaya we-CNC:

Isingeniso somshini:

Umshini wokubhoboza ozenzakalelayo ohlonyiswe ngokulawula izinombolo. Ngemiyalelo yokuhlela ye-CNC, lawula isenzo sesibhoboza bese udala izingxenye.

Isingeniso senqubo:

Ngokusebenzisa inhlanganisela elula yesikhunta, izingxenye ezahlukahlukene zokudlula eziyinkimbinkimbi kanye nokwelula okungajulile kungaqedwa ngesikhathi esisodwa. Kungacubungulwa imigodi emikhulu eyindilinga, imigodi eyisikwele, imigodi okhalweni kanye nezimo ezahlukahlukene zemigoqo egobile. Lokhu kungacubungulwa futhi ngezinqubo ezikhethekile, njengezimpumputhe, izinki eziphikisayo, imigodi ephanyekayo, izimbambo, ukugqokisa, njll.

Umshini wokunyathela we-CNC:

Isingeniso somshini:

Umshini wokunyathela uwumshini wokucindezela. Umshini wokunyathela kanye nesikhunta kusebenzisa amandla angaphandle kumapuleti, imichilo, amapayipi kanye namaphrofayili ukuze kubangele ukuguqulwa noma ukuhlukaniswa kwepulasitiki, ukuze kutholakale isimo nosayizi odingekayo wendlela yokwakha umkhiqizo.

Isingeniso senqubo:

Ngokusebenzisa isikhunta, ukugoqa, ukushaya, ukwakha, ukwelula, ukusika, ukusika kahle, ukubumba, ukugoqa kanye nokukhipha kungenziwa. Ukunemba kokucubungula kuncike kusikhunta kanye nezinto zokwakha. Isikhathi sokushintsha isikhunta kanye nokulungisa isikhathi eside. Izindleko zesikhunta ziphezulu. Kufanelekela imikhiqizo eminingi.

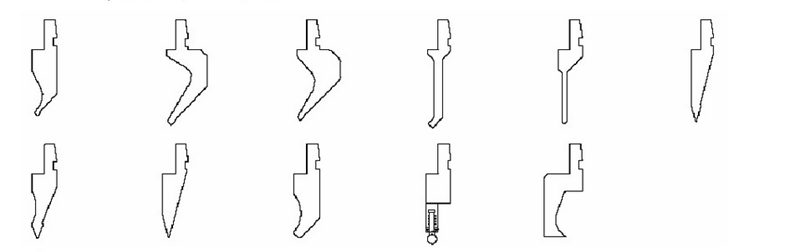

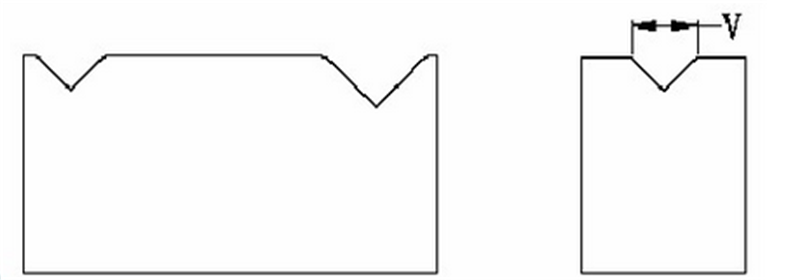

Umshini wokugoba we-CNC:

Isingeniso somshini:

Imishini yokugoba amapuleti amancane ngokusebenzisa izikhunta. Ukusebenza kulula, futhi umsebenzi onodonga oluseceleni ungenziwa. Isivinini esisheshayo, ukunemba okuphezulu, futhi unomsebenzi wokunxephezela okuzenzakalelayo.

Isimo se-die esivamile sokugoba (isikhunta esingaphezulu):

Isimo se-groove evamile engu-V (isikhunta esingezansi):

Umshini wokushisela:

Isingeniso somshini:

Umshini wokushisela uguqula amandla kagesi abe ukushisa ngokushesha. Ungaxhuma ngokushesha izinto zensimbi ezifanayo (futhi ungaxhuma izinsimbi ezingafani, kodwa indlela yokushisela ihlukile) unomphela.

Isingeniso senqubo:

Izindlela ezivamile zokushisela ezingxenyeni zensimbi ezishidi ukushisela ngocingo, ukushisela ngokuncibilikisa kanye nokushisela nge-laser. Ukushisela nge-laser kufanelekile kumapuleti amancane nemikhiqizo enezidingo eziphezulu zobuso. Umshiseli we-AC ushisela izingxenye ze-aluminium. Ukushisela umshini wokushisela we-DC insimbi, insimbi engagqwali, njll.

If you have sheet metal or other metal product fabrication demands, please contact with us freely. We will quote you. Maybe you meet some problem or questions during fabrication or design, also can send into sales1@shhofen.com for help. We are glad to help you.

Isikhathi sokuthunyelwe: Novemba-20-2020