Ma'anar:

Tsarin aiki mai sanyi don faranti na ƙarfe, wanda aka raba shi zuwa sassaka, naushi, lanƙwasawa, riveting, ƙirƙirar mold, walda, da sauransu. Faranti da aka fi amfani da su sun haɗa da faranti masu zafi, faranti masu tsami, faranti masu sanyi, faranti masu galvanized, faranti na jan ƙarfe, faranti na aluminum, bayanan aluminum, faranti na bakin ƙarfe, da sauransu.

Hanyoyin sarrafawa na yau da kullun:

1. Sarrafa faranti na ƙarfe ta hanyar injin cnc, injin lanƙwasa cnc, injin yanke laser, injin yankewa da sauran kayan aiki, wanda galibi ana amfani da shi don samar da samfura da ƙananan rukuni.

2. Ana sarrafa farantin ta hanyar amfani da wani abu mai ƙarfi a kan wani abu mai ƙarfi ko kuma a kan wani abu mai ƙarfi da sauran kayan aiki. Saurin yana da sauri kuma farashin yana da ƙasa, amma farashin injin yana da yawa, shigarwa da maye gurbinsa suna ɗaukar lokaci, kuma galibi ana amfani da shi don samar da kayayyaki da yawa.

Tsarin sarrafa sassan ƙarfe na sheet:

1. Yankan: mold, Laser yankewa, yankewa ko naushi.

2. Samarwa: lanƙwasawa, samar da mold.

3. Sauran sarrafawa: riveting na matsi, riveting ko tapping.

4. Walda: walda ta baka (TIG/MIG), walda mai juriya.

5. Maganin saman jiki: shafa foda, electrophoresis, electroplating, da sauransu.

Kayan aiki na yau da kullun da gabatarwar tsari

Injin aski:

Gabatarwar na'ura:

Injin yanke yana amfani da ruwan wuka mai motsi da kuma ruwan wuka mai ƙayyadadden ... girman da ake buƙata.

Gabatarwar tsari:

Ana amfani da shi wajen yanke tsiri, galibi ana amfani da shi ne don shirya sarrafa tsiri, ko kuma ɓoye sassa masu sauƙi tare da siffofi na yau da kullun. Saurin sauri, ƙarancin farashi, ƙarancin daidaito, ana iya sarrafa tsiri ko tubalan ne kawai ba tare da ramuka da kusurwoyi ba.

Injin yanke Laser:

Gabatarwar na'ura:

Yi amfani da laser mai ƙarfi don haskaka kayan da za a yanke. Ana tururi kayan don ƙirƙirar rami, kuma katakon yana motsawa don samar da tsagewa. Yanke siffar tsarin ɓangaren. Ana buƙatar rubuta shirin laser. Yana iya yanke sassa daban-daban tare da siffofi masu rikitarwa. Babban daidaito. Ana amfani da shi galibi don samar da samfura ko nau'ikan ƙananan samfura da yawa.

Gabatarwar tsari:

Girman katakon yanke laser yana da ƙanƙanta sosai, yawanci ƙasa da 0.2MM. Lokacin yanke faranti na ƙarfen carbon ƙasa da 3mm, ana iya sarrafa juriyar nisan tsakiyar ramin a cikin 0.05MM, ana iya sarrafa juriyar kwane-kwane a cikin 0.1MM, kuma ƙaiƙayin saman zai iya kaiwa Ra 12.5. Laser ɗin zai bar alamomi a saman yanke. Faranti mai kauri, mafi bayyane.

Abubuwan da ke tasiri ga yanke laser:

Ƙaramin wurin yanke laser, ƙaramin ramin, mafi girman daidaito;

Mafi girman daidaiton matsayi na teburin aiki, mafi girman daidaiton yanke laser;

Mafi kauri takardar, ƙarancin daidaiton yanke laser da kuma mummunan taurin saman;

Da irin wannan kauri, daidaiton farantin ƙarfe ya fi farantin aluminum girma, kuma saman yankewa yana da santsi;

Injin CNC na'ura mai sarrafawa:

Gabatarwar na'ura:

Injin huda kai tsaye wanda aka sanye shi da na'urar sarrafa lambobi. Ta hanyar umarnin shirye-shiryen CNC, sarrafa aikin huda sannan a ƙera sassan.

Gabatarwar tsari:

Ta hanyar haɗakar mold mai sauƙi, ana iya kammala nau'ikan sassa masu rikitarwa da marasa zurfi a lokaci guda. Yana iya sarrafa manyan ramuka masu zagaye, ramuka masu murabba'i, ramukan kugu da siffofi daban-daban na lanƙwasa. Hakanan ana iya sarrafa wannan ta hanyar hanyoyi na musamman, kamar su mayafi, matsewa, ramuka masu lanƙwasa, haƙarƙari, embossing, da sauransu.

Injin tambarin CNC:

Gabatarwar na'ura:

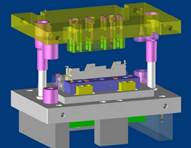

Injin tambari injin matsi ne. Injin tambari da mold suna amfani da ƙarfi na waje a kan faranti, tube, bututu da bayanan martaba don haifar da nakasa ko rabuwar filastik, don samun siffar da girman da ake buƙata ta hanyar samar da samfurin.

Gabatarwar tsari:

Ta hanyar mold, ana iya yin blanking, hudawa, samar da abu, shimfiɗawa, gyarawa, tsaftace shi, siffanta shi, riveting da extrusion. Daidaiton sarrafawa ya dogara da mold da kayan aiki. Sauya mold da lokacin daidaitawa ya fi tsayi. Kudin mold yana da yawa. Ya dace da samfuran da yawa.

Injin lanƙwasa na CNC:

Gabatarwar na'ura:

Kayan aiki don lanƙwasa faranti masu sirara ta cikin molds. Aikin yana da sauƙi, kuma ana iya ƙera kayan aikin da ke da bangon gefe. Sauri, daidaito mai yawa, kuma yana da aikin diyya ta atomatik.

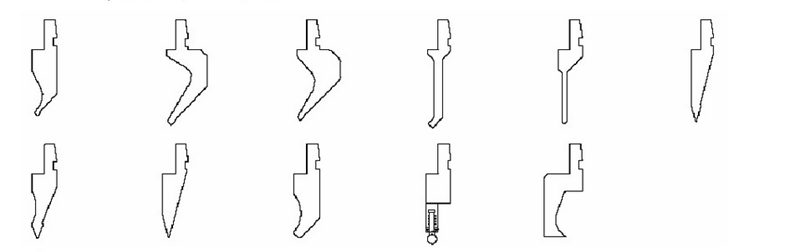

Siffar lanƙwasa ta gama gari (ƙafafun saman):

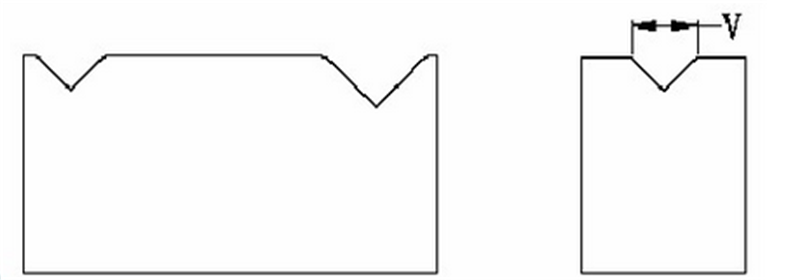

Siffar tsagi na V na gama gari (ƙasa da mold):

Injin walda:

Gabatarwar na'ura:

Injin walda nan take yana mayar da makamashin lantarki zuwa zafi. Yana iya haɗa kayan ƙarfe iri ɗaya nan take (kuma yana iya haɗa ƙarfe daban-daban, amma hanyar walda ta bambanta) har abada.

Gabatarwar tsari:

Hanyoyin walda da aka fi amfani da su a sassan ƙarfe na takarda sune walda ta waya, walda ta narkewa da walda ta laser. Walda ta laser ta dace da faranti masu siriri da samfuran da ke da buƙatar saman da ya dace. Walda ta AC tana walda sassan aluminum. Walda ta DC tana walda ƙarfe, bakin ƙarfe, da sauransu.

If you have sheet metal or other metal product fabrication demands, please contact with us freely. We will quote you. Maybe you meet some problem or questions during fabrication or design, also can send into sales1@shhofen.com for help. We are glad to help you.

Lokacin Saƙo: Nuwamba-20-2020