Inkcazo:

Inkqubo ebanzi yokusebenza ngokubanda kwepleyiti yesinyithi, eyahlulwe ngokubanzi kukusika, ukubhoboza, ukugoba, ukugoba, ukwenza isikhunta, ukuwelda, njl. Iipleyiti ezisetyenziswa rhoqo ziquka iipleyiti ezigoqiweyo ezishushu, iipleyiti ezicoliweyo, iipleyiti ezigoqiweyo ezibandayo, iipleyiti ze-galvanized, iipleyiti zobhedu, iipleyiti ze-aluminium, iiprofayili ze-aluminium, iipleyiti zentsimbi engagqwaliyo, njl.

Iindlela eziqhelekileyo zokucubungula:

1. Ukucutshungulwa kweepleyiti ngesinyithi esenziwe ngomatshini wokubhoboza we-cnc, umatshini wokugoba we-cnc, umatshini wokusika nge-laser, umatshini wokucheba kunye nezinye izixhobo, ezisetyenziswa kakhulu kwimveliso yesampulu kunye nebhetshi encinci.

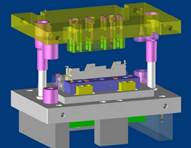

2. Ipleyiti icutshungulwa ngesikhunta esizinzileyo kwi-punch okanye kwi-press nakwezinye izixhobo. Isantya siyakhawuleza kwaye ixabiso liphantsi, kodwa ixabiso lesikhunta liphezulu, ukufakelwa nokutshintshwa kuthatha ixesha elide, kwaye isetyenziselwa kakhulu ukuvelisa ngobuninzi.

Inkqubo yokucubungula iindawo zesinyithi:

1. Ukusika: ukungunda, ukusika nge-laser, ukucheba okanye ukubhoboza.

2. Ukubumba: ukugoba, ukwenza umngundo.

3. Okunye ukucubungula: ukubethela ngoxinzelelo, ukubethela okanye ukuthepha.

4. Ukuwelda: ukuwelda nge-arc (TIG/MIG), ukuwelda ngokumelana.

5. Unyango lomphezulu: i-powder coating, i-electrophoresis, i-electroplating, njl.

Izixhobo eziqhelekileyo kunye nentshayelelo yenkqubo

Umatshini wokucheba:

Intshayelelo yomatshini:

Umatshini wokucheba usebenzisa i-blade ephezulu ehambayo kunye ne-blade esezantsi ezinzileyo, kwaye usebenzisa isithuba esifanelekileyo se-blade ukufaka amandla okucheba kumashiti esinyithi anobukhulu obahlukeneyo ukuze amaphepha aqhekeke aze ahlukane ngokobukhulu obufunekayo.

Intshayelelo yenkqubo:

Isetyenziselwa ukusika imicu, isetyenziselwa kakhulu ukulungiselela ukucutshungulwa kwe-die blanking, okanye ukucutshungulwa kweendawo ezilula ezineemilo eziqhelekileyo. Isantya esikhawulezayo, ixabiso eliphantsi, ukuchaneka okuphantsi, inokucubungula imicu okanye iibhloko kuphela ezingenamingxuma kunye neekona.

Umatshini wokusika nge-laser:

Intshayelelo yomatshini:

Sebenzisa i-laser enamandla aphezulu ukuze ukhanyisele izinto eziza kusikwa. Izinto ziyafuthwa ukuze zenze umngxuma, kwaye umqadi uhamba ukuze wenze umngxuma. Sika imilo yesakhiwo senxalenye. Kufuneka ubhale inkqubo ye-laser. Ingasika iindawo ezahlukeneyo ezineemilo ezintsonkothileyo. Ukuchaneka okuphezulu. Isetyenziswa kakhulu kwimveliso yesampulu okanye kwiintlobo ngeentlobo zemveliso encinci.

Intshayelelo yenkqubo:

Ububanzi bomqadi wokusika nge-laser buncinci kakhulu, buhlala bungaphantsi kwe-0.2MM. Xa usika iipleyiti zentsimbi yekhabhoni ezingaphantsi kwe-3 mm, ukunyamezelana komgama phakathi kwemingxuma kunokulawulwa ngaphakathi kwe-0.05MM, ukunyamezelana kwe-contour kunokulawulwa ngaphakathi kwe-0.1MM, kwaye uburhabaxa bomphezulu bunokufikelela kwi-Ra 12.5. I-laser iya kushiya amanqaku kumphezulu wokusika. Okukhona ipleyiti ityebile, kokukhona icacile.

Izinto ezichaphazela ukusika nge-laser:

Okukhona indawo yokusika nge-laser incinci, kokukhona umngxuma uncinci, kokukhona ukuchaneka kuphezulu;

Okukhona ukuchaneka kokubekwa kwetafile yokusebenza kuphezulu, kokukhona ukuchaneka kokusika nge-laser kuphezulu;

Okukhona iphepha lijiyile, kokukhona ukuchaneka kokusikwa nge-laser kunciphisa kwaye kokukhona uburhabaxa bomphezulu busiba bubi;

Ngobukhulu obufanayo, ukuchaneka kwepleyiti yentsimbi kuphezulu kunepleyiti ye-aluminium, kwaye umphezulu wokusika uthambile;

Umatshini wokubhoboza we-CNC:

Intshayelelo yomatshini:

Umatshini wokubhoboza ozenzekelayo oxhotyiswe ngolawulo lwamanani. Ngemiyalelo yenkqubo ye-CNC, lawula isenzo sesibhoboza uze wenze iindawo.

Intshayelelo yenkqubo:

Ngokusebenzisa indibaniselwano elula yokubumba, iintlobo ngeentlobo zeepasi ezintsonkothileyo kunye neendawo ezolulekileyo ezinganzulu zingagqitywa ngexesha elinye. Ingacubungula imingxunya emikhulu engqukuva, imingxunya yesikwere, imingxunya yesinqe kunye neemilo ezahlukeneyo zemilo egobileyo. Oku kungenziwa nangeenkqubo ezikhethekileyo, ezinje ngeeblinds, ii-countersink, imingxunya eflangiweyo, iimbambo, ukugquma, njl.njl.

Umatshini wokunyathela we-CNC:

Intshayelelo yomatshini:

Umatshini wokunyathela ngumatshini woxinzelelo. Umatshini wokunyathela kunye nomngundo zifaka amandla angaphandle kwiipleyiti, imicu, iipayipi kunye neeprofayili ukuze kubangele ukuguquka okanye ukwahlukana kweplastiki, ukuze kufunyanwe imo kunye nobukhulu obufunekayo bendlela yokwenza imveliso.

Intshayelelo yenkqubo:

Ngokusebenzisa isikhunta, ukugquma, ukubhoboza, ukwenza, ukolula, ukusika, ukucola isikhunta, ukubumba, ukugoba kunye nokukhupha izinto kungenziwa. Ukuchaneka kokucubungula kuxhomekeke kwisikhunta kunye nezinto. Ixesha lokutshintsha isikhunta kunye nokulungisa ixesha elide. Ixabiso lesikhunta liphezulu. Ifanelekile kwiimveliso ezinkulu.

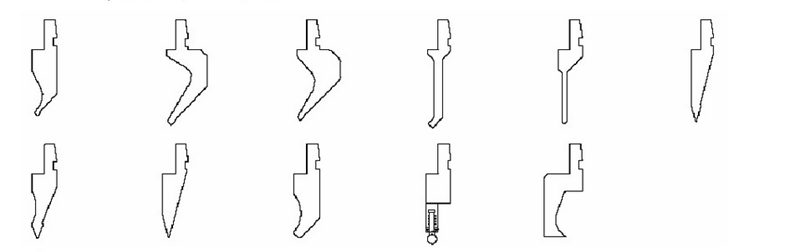

Umatshini wokugoba we-CNC:

Intshayelelo yomatshini:

Izixhobo zokugoba iipleyiti ezibhityileyo ngokusebenzisa iimolds. Umsebenzi ulula, kwaye umsebenzi onodonga olusecaleni ungenziwa. Isantya esikhawulezayo, ukuchaneka okuphezulu, kwaye unomsebenzi wokubuyisela ngokuzenzekelayo.

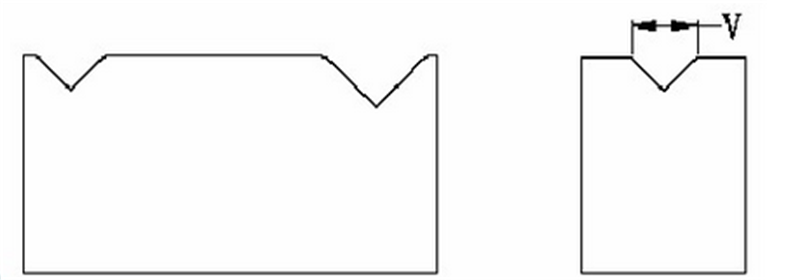

Imilo eqhelekileyo yokugoba idayisi (umngundo ongaphezulu):

Imilo ye-groove eqhelekileyo ye-V (umngundo osezantsi):

Umatshini wokuwelda:

Intshayelelo yomatshini:

Umatshini wokuwelda uguqula amandla ombane abe bubushushu ngoko nangoko. Ungadibanisa ngoko nangoko izinto zesinyithi ezifanayo (ungadibanisa neentsimbi ezahlukeneyo, kodwa indlela yokuwelda yahlukile) ngokusisigxina.

Intshayelelo yenkqubo:

Iindlela eziqhelekileyo zokuwelda kwiindawo zesinyithi kukuwelda ngocingo, ukuwelda ngokunyibilikisa kunye nokuwelda nge-laser. Ukuwelda nge-laser kufanelekile kwiipleyiti ezincinci kunye neemveliso ezineemfuno eziphezulu zomphezulu. Umwelda we-AC uwelda iindawo ze-aluminiyam. Ukuwelda ngomatshini wokuwelda we-DC isinyithi, intsimbi engatyiwayo, njl.njl.

If you have sheet metal or other metal product fabrication demands, please contact with us freely. We will quote you. Maybe you meet some problem or questions during fabrication or design, also can send into sales1@shhofen.com for help. We are glad to help you.

Ixesha lokuposa: Novemba-20-2020