I-Aluminium iyinsimbi eguquguqukayo evame ukusetshenziswa ezimbonini ezahlukahlukene ezihlanganisa ezokwakha, ezokuthutha kanye nokupakisha. Ukwenziwa kwe-aluminium kuyisici esibalulekile sokuguqula ukusetshenziswa kwalesi sici embonini yesimanje. Ukwenziwa kwe-Aluminium kusho inqubo yokuklama, ukusika nokushisela i-aluminium ukuze kwakhiwe izakhiwo noma imishini ehlangabezana nezidingo ezithile zezimboni.

I-Aluminium inezinto ezihlukile eziyenza ilungele ukwenziwa. Ilula, imelana nokugqwala, futhi inokuhamba kahle kakhulu kwe-thermal kanye nogesi. Le nsimbi futhi iqinile, iyathandeka futhi iyabonakalisa kakhulu. Zonke lezi zakhiwo zenza izinsimbi zibe izinto ezinhle kakhulu zokwenziwa kwemikhiqizo ehlukene.

Inqubo yokukhiqiza ibandakanya izigaba eziningana ezihlanganisa ukuklama, ukusika kanye nokushisela. Isinyathelo sokuqala sibandakanya ukuklanywa kwesakhiwo noma umshini ozokwenziwa. Inkampani ekhiqizayo izosebenzisana eduze nekhasimende ukuze inqume ukusetshenziswa komkhiqizo, imininingwane ethile, nezinye izidingo.

Uma inqubo yokuklama isiqediwe, isigaba esilandelayo siwukusika. Inqubo ihilela ukusika i-aluminium ibe ngusayizi oyifunayo kanye nokuma usebenzisa amathuluzi okusika akhethekile kanye nemishini. Ukusika kungenziwa ngokusebenzisa izindlela ezahlukene ezihlanganisa ukusika nge-laser, ukusika nokugunda.

Ngemva kokusika, isigaba esilandelayo siwukushisela. Inqubo ihilela ukujoyina izingcezu ezahlukene ze-aluminium usebenzisa umshini wokushisela. Ukushisela kwenza izinkampani ezikhiqizayo zenze izakhiwo eziqinile neziqinile ezingamelana nezidingo zezimboni ezihlukahlukene.

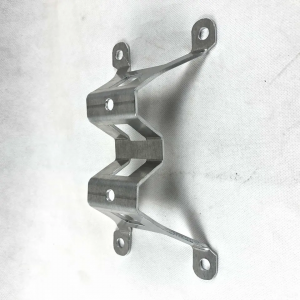

Enye yezinzuzo zokwenziwa kwe-aluminium ukuguquguquka kwayo. I-Aluminium ingenziwa ibe yizinhlaka ezahlukene ezihlanganisa amagobolondo, amafreyimu, amaphaneli kanye nezakhiwo zokusekela.

Ukusetshenziswa kokwakhiwa kwe-aluminiyamu kuguqule izimboni ezihlukahlukene kusukela kwezokuthutha kuya emkhathini. Izakhiwo ze-Aluminium ezingasindi futhi zimelana nokugqwala ziyenza ilungele ukukhiqiza izingxenye ezihlukene zezindiza nemikhumbi-mkhathi. Ukusetshenziswa kwe-aluminium futhi kuqinisekisa ukusebenza kahle kukaphethiloli endizeni ngenxa yesisindo sayo esincane.

Embonini yezokwakha, ukwakhiwa kwe-aluminium kuvame ukusetshenziselwa ukukhiqiza amafasitela, iminyango nezinye izingxenye zokwakha. Ukwakhiwa kwe-aluminium kuhlala isikhathi eside, ukumelana nokugqwala futhi kulula ukukugcina, okwenza kube ukukhetha okuhle kakhulu kubakhi.

Ukwenziwa kwe-aluminium kuyinqubo evumelana nemvelo njengoba i-aluminium ikwazi ukugaywa kabusha futhi akukho ntuthu eyingozi ephumayo phakathi nenqubo yokukhiqiza. Ukugaywa kabusha kwe-aluminium konga kuze kufike ku-90% wamandla adingekayo ukuze kukhiqizwe i-aluminium entsha.

E-Hongfeng Machinery (Shanghai) Co., Ltd., siyaziqhenya ngokuhlinzeka ngekhwalithi nezinsiza ezisebenzayo zokucubungula i-aluminium. Ithimba lethu lochwepheshe abanamakhono nabanolwazi lisebenzisa ubuchwepheshe bamuva kanye nemishini ukuklama, ukusika nokushisela izakhiwo nemishini ye-aluminium yezidingo zezimboni ezahlukene.

Sizibophezele ekuhlinzekeni ngemikhiqizo ye-aluminium yangokwezifiso ehlangabezana nezidingo eziyingqayizivele zamakhasimende ethu. Sisebenzisana eduze namakhasimende ethu ukuze siqinisekise ukuthi siyaziqonda izidingo zawo, imininingwane kanye nesabelomali. Lokhu kusenza sikwazi ukuhlinzeka ngezixazululo ezingabizi kakhulu ezidingweni zabo zezimboni.

Sengiphetha, zokwenziwa kwe-aluminium kuyinqubo ebalulekile yokuguqula izimboni ezahlukene, kusukela ku-aerospace kuya kwezokwakha. Isisindo esilula, ukumelana nokugqwala kanye nokugaywa kabusha kwe-aluminium kuyenza ilungele ukukhiqiza imikhiqizo ehlukene. Kwa-Hoffen Machinery (Shanghai) Co., Ltd., sizibophezele ekuhlinzekeni ngemikhiqizo ye-aluminium yezinga eliphezulu ehlangabezana nezidingo ezihlukile zamakhasimende ethu kanye nokucaciswa kwawo. Xhumana nathi namuhla ukuze ufunde kabanzi mayelana nezinsizakalo zethu zokwenziwa kwe-aluminium.

Isikhathi sokuthumela: May-08-2023