Powder coat is to use powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of the workpiece. Under the action of static electricity, a powdery coating is formed, which is baked and leveled and cured at high temperature to become the final coating.

Powder spraying uses the principle of electrostatic spraying to adsorb dry powder on the metal surface. After baking at a high temperature above 200 °C, the powder is cured into a solid and bright coating with a thickness of about 60 microns. Make the surface of the product smooth and uniform, with strong acid resistance, alkali resistance, crash resistance and wear resistance.

It can withstand the erosion of strong ultraviolet radiation and acid rain for a long time without coating chalking, fading and falling off.

The spraying effect of powder spraying is superior to the spraying process in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance, but the cost is higher than that of the spraying process.

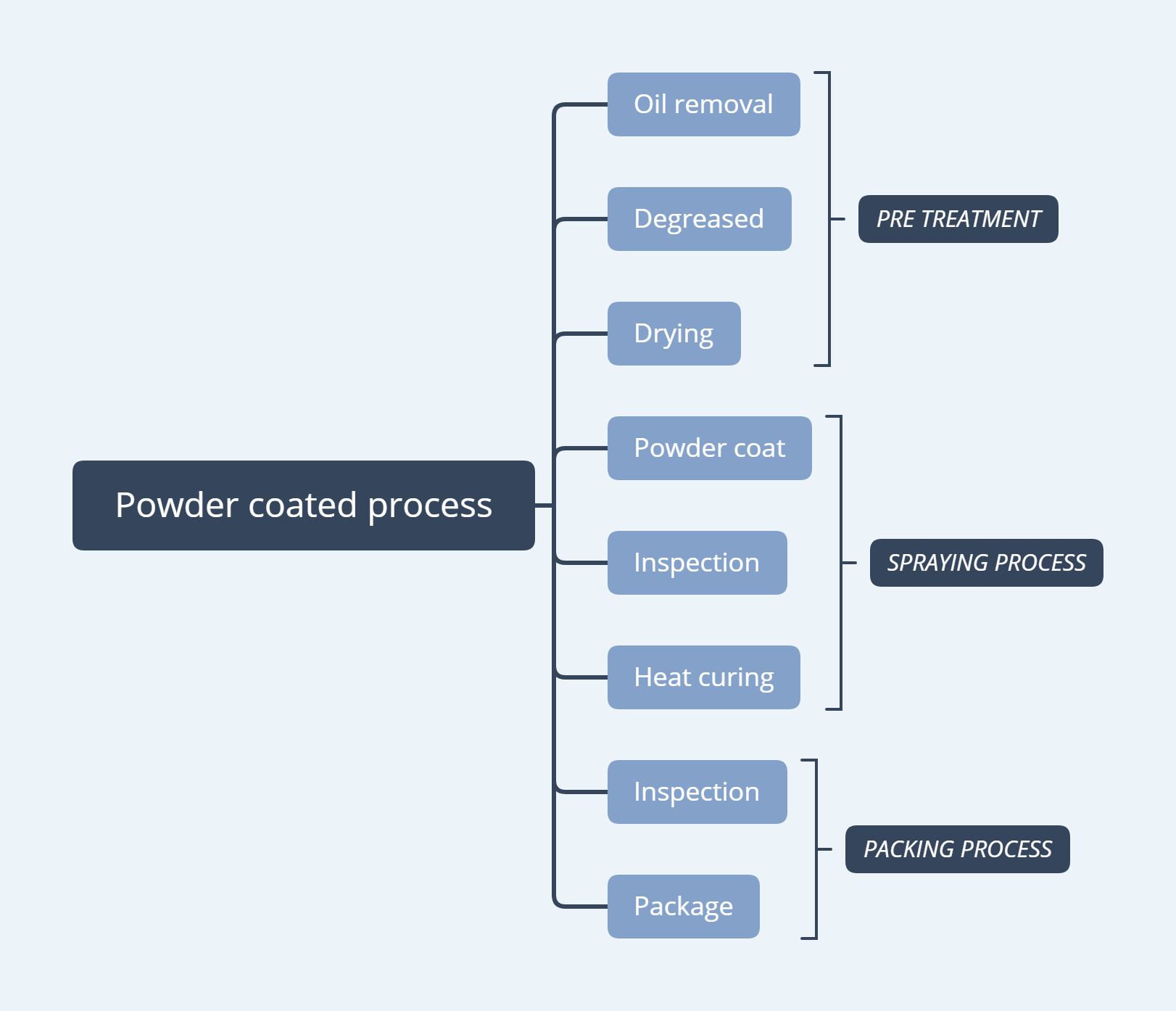

Powder coating process

Degreasing, degreasing, drying, dusting, inspection, heat curing, inspection, packaging.

Next Post: Powder coating instruction-2

Post time: Oct-08-2022